How do supply chain choices impact offshore wind emissions?

By Eloïse Ducreux, Spinergie

Offshore wind is a key pillar of the energy transition, providing a low-carbon alternative to fossil fuels. However, its life-cycle emissions are not negligible. Component manufacturing is the most significant contributor to emissions, but supply chain transport choices also play a significant part.

Varying emission levels are created during the transportation of turbine components, depending on which logistical decisions have been made. This makes optimization crucial to reducing offshore wind’s environmental footprint.

The offshore industry is actively working toward standardization, with initiatives like the Carbon Trust's Product Carbon Footprint standards. However, data collection and detailed studies on maritime transport emissions still need to be expanded. Here, Spinergie quantifies how supply chain choices impact the emissions generated by a campaign, highlighting the need for a deeper understanding of logistics-related carbon impacts.

Supply chain considerations in offshore wind

Supply chain decisions impact the cost, timeline and emissions profile of offshore wind projects. Choosing where components are manufactured and how they are transported can lead to vastly different emissions outcomes.

Localizing supply chains can reduce transport distances while global manufacturing hubs often offer lower production costs. Yet, beyond price considerations, many regulatory frameworks and project tenders increasingly emphasize non-priced criteria, including local content requirements, environmental impact and job creation.

Striking the right balance between these trade-offs requires a data-driven approach that considers both economic and regulatory factors.

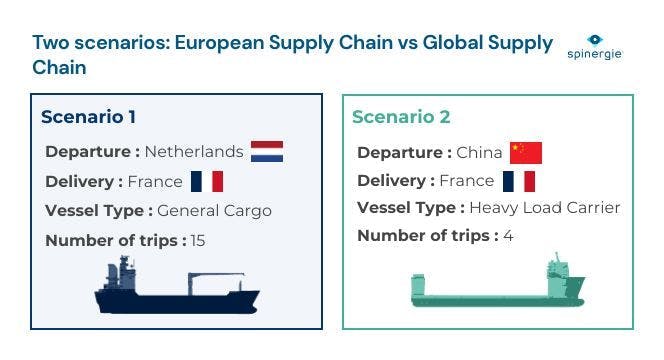

Comparing two transport scenarios for monopiles

To illustrate the impact of transport decisions, Spinergie analyzed two real-world scenarios for the delivery of 60 monopiles to a logistic port in France. These monopiles must be transported from their manufacturing location to the marshaling yard.

Scenario 1: European supply chain

- Origin: The Netherlands

- Transport method: General cargo with four monopiles onboard

- Number of round trips required: 15

Scenario 2: Global supply chain

- Origin: China

- Transport method: Heavy-load carrier with 10 to 20 monopiles onboard

- Number of round trips required: Four

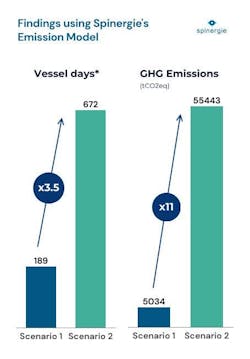

The greenhouse gas (GHG) impact of the two scenarios for the French offshore wind development has been evaluated using the Spinergie Offshore Emissions Model (SOEM).

To quantify the emissions impact of these scenarios, the SOEM integrates:

- Vessel characteristics (engine type, fuel consumption and efficiency);

- Operational activities and speeds (including transit, loading and unloading); and

- Full trip-by-trip emissions calculations to determine total GHG emissions.

Takeaways

Transporting monopiles from China resulted in GHG emissions 11 times higher compared to a European supply chain.

The difference was driven primarily by the long transit distances, even though the heavy load carriers used were more efficient in terms of capacity per trip.

These additional emissions could negate the cost savings from cheaper production in China, particularly with the introduction of the European Emissions Trading System, which imposes a financial cost on GHG emissions.

Decarbonizing supply chain transport & the way forward

These findings highlight the importance of incorporating emissions impact into supply chain decisions. While cost and logistics remain key factors, developers must also consider the full life-cycle emissions of their projects.

To achieve long-term decarbonization goals, the offshore wind sector should:

- Optimize transport routes and methods to minimize emissions without compromising cost-effectiveness;

- Encourage regional manufacturing where feasible to reduce transport-related emissions; and

- Expand emissions modeling beyond transport to include the full life cycle of offshore wind farms, from material sourcing to end-of-life decommissioning.

By integrating emissions modeling into procurement strategies, offshore wind developers can make data-driven decisions that align with both economic and environmental goals.

About the Author

Eloïse Ducreux

Eloïse Ducreux is an offshore sustainability analyst with Spinergie, a maritime technology company. She first joined Spinergie as a Stagiaire data analyst intern in April 2023 and was then hired in December 2023 for her current role.

She has also been a workshop facilitator with 2tonnes since May 2021, focusing on actions that will bring about a direct change in greenhouse-gas emissions.