Offshore wind moving into deeper waters with reimagined technology

Editor's note: This feature first appeared within the 2024 Offshore Wind Special Report and published within the July/August issue of Offshore magazine.

By Garry Stephen, Oil States

Current offshore wind development has primarily been in nearshore water depths, as the dynamic floating wind environment complicates critical platform and turbine stability. Offshore wind platforms that rely on monopiles are now approaching 40-m water depths while jackets are reaching 50 m. A 15+MW turbine can reach 150 m tall and weigh approximately 500 metric tonnes. Beyond that 50-m water depth, fixed structures become uneconomic due to their large jacket sizes.

This has created a conundrum that has hindered the expansion of offshore wind use, as a higher quality wind resource that’s capable of driving these larger turbines is found farther from shore in much deeper water. This has led to additional technical complexity that extends beyond the cost-effective limit for monopiles or conventional jacket structures.

For these deeper waters, the offshore wind market has focused on floating platforms including semisubmersibles and SPARs. However, those floating platforms heave, pitch and roll with the waves, and those factors are inherently problematic. These movements can reduce a turbine’s operational weather window and reliability.

The offshore wind sector not only faces these technical obstacles to pushing farther into the oceans past 50 m but also must address three additional and equally pivotal concerns. First, the manufacturability of deeper-water platforms is a substantial challenge. The offshore wind industry requires manufacturing facilities that would demand billions of dollars in investment to build.

Second, the offshore wind industry lacks critical volume delivery capabilities. This is essential to be able to scale.

Third, local content is a requirement for offshore wind projects for several reasons. Limited manufacturing capabilities can undermine offshore wind developers’ ability to satisfy local content stipulations.

Oil and gas makes offshore wind advancements possible

When it comes to the deepwater environment, the oil and gas industry has hard-won expertise and established infrastructure that resolves many of these formidable challenges. Tension-leg platforms (TLPs) have been used for offshore oil and gas production since the early 1980s and have traditionally been the best method for navigating the greater water depths that this procurement demands. TLP technology has been field-proven in deepwater applications for decades.

As this technology has been successfully used for several years, the oil and gas industry offers a stable existing supply chain with established fabrication capabilities. This eliminates the need to build costly new manufacturing centers.

The oil and gas industry is well positioned when it comes to meeting volume demands. With the ability to easily utilize existing national and international infrastructure, scaling up isn’t as daunting.

Additionally, the oil and gas industry’s global footprint helps create jobs in multiple locations. This equips the industry to satisfy offshore wind developers’ needs for local content.

Utilizing proven technology

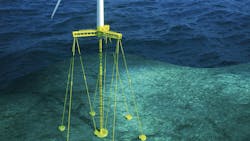

Having technology installed on 95% of the world’s TLP mooring systems, Oil States has leveraged its deepwater TLP learnings in the patent-pending FTLP Floating Wind Platform to bring the advantages of a fixed wind foundation into deeper waters—up to 150-m water depth—while minimizing the levelized cost of energy (LCOE) across the offshore wind life cycle.

The stability of the FTLP minimizes tower weight, removes the need for dynamic cabling, and minimizes turbine movement and acceleration, which is a leading cause of turbine fatigue. This helps offshore wind operators reduce total cost of ownership.

While meeting the rigorous technical demands for pushing past 50-m water depths, this technology can be cost-effectively manufactured at scale in local markets. Lowering costs has a positive impact on the speed at which developers can deploy deeper water offshore wind projects and reduces the LCOE for consumers. Every million dollars saved on an individual installation equates to a global price reduction that can be exponentially greater.

Expanding offshore wind’s potential

From reducing accelerations on the rotational equipment within the turbine nacelle to offering a fixed subsea cable connection, the FTLP overcomes many of the challenges of creating a reliable, cost-effective offshore wind energy system within the structures’ target-water depth of 50 m to 150 m.

The rich heritage of the oil and gas industry makes this step change in the stability, maintenance requirements, harbor depth and draft, economics and feasibility for floating arrays possible. Importantly, this technology has been proven in offshore oil fields for decades, giving offshore wind developers greater confidence to bid and advance projects within this deeper target-water depth. As the world’s energy needs grow, oil and gas will inform and expand the energy sources needed to meet the demand.

About the Author

Garry Stephen

Garry Stephen is group vice president, UK and Asia, with Oil States, a role he has held since 2019.

Previously, he served as the company's managing director from January 2012 to March 2019.

Prior to his time with Oil States, he worked with other industry companies such as Cameron, Expro and Aker Solutions.

He is based in Aberdeen, UK.