Hydrogen presents opportunity for aging offshore facilities

Many of the coastal shallow waters that once bore an abundance of oil/gas deposits have long been exploited, leaving behind a plethora of aging platforms. There are few places this has been more apparent than in the Gulf of Mexico, where there are over 2,000 offshore platforms. A significant proportion of these platforms are nearshore and are approaching the end of their practical life or are already effectively redundant, sucking up the last drops to avoid the label of “Idle Iron.” Once a platform falls into the “Idle Iron” category, the operator has the obligation to undertake the inevitable expense of decommissioning.

Some of these defunct offshore petroleum platforms have found a new lease on life in the form of artificial reefs. In the Gulf of Mexico alone, there have been at least 532 such projects. The success of the platform-to-reef programs is well documented and will continue to offer operators an alternative to full removal. In addition to artificial reefs, another option is to convert the platform into an offshore wind turbine foundation. This idea has failed to gain much traction over the years, possibly due to the cost of installing a large wind turbine. The system would also require a network of expensive submarine power cables to bring the electric power ashore.

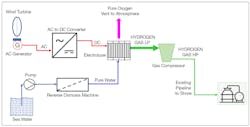

UniversalPegasus International (UPI) has undertaken initial studies related to the feasibility of converting defunct offshore platforms into offshore wind turbine foundations. The firm believes that there is a realistic way to bring power generated from an offshore wind turbine ashore without the need to install a lengthy submarine cable. UPI has determined that a more elegant, and definitely greener solution would be to generate electricity from a wind turbine installed on an existing defunct oil/gas platform jacket; convert the electricity to hydrogen (on site); then pump the hydrogen gas ashore using the existing petroleum pipelines, into existing terminal facilities. The result is not just holistically more environmentally sympathetic, but can also provide a swifter turnaround from carbon generating energy to non-carbon renewable energy.

Amidst the range of policies being considered to combat climate change, the possibility of turning to hydrogen as a fuel source is gaining momentum. Indeed, some countries have already made bold commitments to hydrogen. For example, India, a nation of a billion people and growing, has set the lofty goal of eliminating petroleum-based fuel for transport by 2050 and replacing it with hydrogen and electric-powered vehicles.

Fortunately, the humble hydrogen atom just happens to be the most abundant element in the universe, and here on Earth we are blessed with so much hydrogen that not even mankind can exploit it to the limit. So, there we are. The energy question has been solved; an end to climate change is in site; the Earth is saved...but wait. There is a catch. The caveat being that unfortunately on Earth, this abundant hydrogen is locked up along with our other friend, the oxygen atom. Teamed with hydrogen, we call it H2O, or more affectionately – “water.” The irony is that to affect a divorce of the hydrogen from the oxygen such that it can be used as fuel requires the input of a large charge of electrical energy. The most commonly used device to force apart the bond between hydrogen and oxygen is called an “electrolyzer,” which uses the simple process of electrolysis to effect this change. The most common form of industrial electrolyzers are specifically called polymer electrolyte membrane (PEM) electrolyzers.

In a PEM electrolyzer, the electrolyte takes the form of a solid plastic membrane which only allows positive hydrogen ions (H+), otherwise known as protons, to pass through. Water (H2O) reacts with the anode to form oxygen (O2) gas. The electrons flow around the DC circuit from anode to cathode. At the cathode, hydrogen (H) gas is formed as the positive hydrogen ions (H+) combine with the negative electrons (e-).

The offshore wind to onshore hydrogen process being advocated by UPI described is as follows:

1. Select a collection of oil/gas platforms (of conventional jacket structure) that are at or near end of practical petroleum production.

2. Fully decommission the topsides of all but one of the platforms. Leave one platform designated as a “gathering platform” which has at least one redundant export gas pipeline to shore.

3. On the fully decommissioned jacket platform, install a single horizontal axis turbine or an array of vertical axis wind turbines.

4. Link the array of wind turbine jacket platforms with an infield submarine electric cable.

5. On the gathering platform, remove all the oil/gas process facilities and replace them with a unitized offshore hydrogen generating plant.

6. The hydrogen gas generated is then pumped ashore through existing refurbished gas pipeline to an existing onshore facility.

There currently exist two main types of wind generator: horizontal axis and vertical axis turbines. These are described below.

Horizontal axis wind turbines. These are the most popular form of wind turbine for both onshore and offshore applications. The generator sits atop of a large tower and rotated by large propellor type blades. As of January 2021, the largest horizontal axis wind turbine (HAWT) is currently rated at 14-MW power output. The size and efficiency of HAWTs continues to improve as the economic demand continues to rise.

Vertical axis wind turbines. These are not so common and tend to be significantly smaller (circa 1.5 MW max size), and supposedly less efficient at trapping the wind energy. However, VAWTS still have a niche in the market, especially in areas where it is not feasible or practicable to use large high lift cranes, as the generator section is located at the base of the unit.

Most oil and gas platforms situated in shallow coastal waters tend to be of a simple four-leg jacket design that were originally built for an average 15,000 metric tons topside weight. When the oil/gas production ceases, the platform can be partially decommissioned and the main part of the original platform removed. A standard 5MW horizontal axis wind turbine normally weighs in at less than 1,000 metric tons. A series of four vertical axis wind turbines, if selected, would likely weigh in at a total of just 200 metric tons (4 x 50 metric tons). The weight of the reverse osmosis plant, AC/DC inverters, electrolyzers, gas compressors, and ancillary equipment all come in well under 100 metric tons each and collectively well under 500 metric tons. Even allowing for more dynamic loading and more bending moments due to the wind turbine reaction forces, most of the jackets should have sufficient load utilization. Thus, UPI deems a 5 MW output per shallow-water platform to be a reasonable starting point.

The offshore hydrogen generation process is described in a little more detail as follows:

1. Seawater is drawn up to the platform using existing fire water and process water risers.

2. Seawater is passed through a reverse osmosis plant. It should be noted that raw seawater could be used, but the resulting salts would hinder the electrolysis process and leave an undesirable industrial waste product which itself would need to be disposed of.

3. The electricity generated from the wind turbine is AC; this needs to be transformed into DC using a rectifier.

4. The pure H2O from the reverse osmosis plant and the DC electricity is fed to the electrolyzer.

5. The hydrogen gas produced is then collected, passed through a gas compressor, and is then pumped down the re-commissioned gas pipeline to the onshore facility.

All of the key components are readily available to industry, and significantly the electrolyzers are becoming larger and more efficient as the demand for hydrogen increases globally.

One of the byproducts of the electrolysis process is oxygen. This oxygen “byproduct” can be simply vented into the atmosphere for the general benefit of life on Earth or it too can be piped to an onshore facility and sold as another commodity. Even if this process was to become widespread, there is little fear of over-oxygenating the atmosphere as sadly deforestation still adversely tips the global oxygen balance. Initial studies conducted by UPI indicate that despite there being an opportunity to produce marketable quantities of pure oxygen, the net value might not warrant the cost of re-commissioning a second export pipeline along with the risks of pumping pure O2. It is also worth considering that as numerous nations start to apply a carbon tax on energy providers and users alike, there is potential for credit against a levied carbon tax in the venting of oxygen to atmosphere or ocean.

Thus, the science and engineering behind the concept of generating hydrogen from wind turbines on re-used oil/gas platforms is sound. But what about the economics?

There are industrial PEM electrolyzers currently on the market that can produce up to 200 nominal cubic meters (Nm3) of hydrogen (99% pure) per hour per MW power. The 200 Nm3/hr production of hydrogen equates to some 17.9 kg/hr. Thus, an uninterrupted production could yield nearly 160,000 kg of hydrogen a year from a one MW supply.

Remember that oxygen (O2) is a byproduct of the electrolysis process and approximately half that of the hydrogen quantity by volume is produced (ie, 100 Nm3/hr). Oxygen is much heavier than hydrogen, thus the weight of oxygen produced per MW of power could be as much as 143 kg/hr. Likewise, an uninterrupted production could yield nearly 1,251 metric tons of oxygen a year from a one-megawatt supply.

There is no doubt that as the 21st century progresses, existing oil and gas producers will morph into “energy providers,” as indeed some are already labeling themselves. And, there is increasing political pressure for significant changes in the use of fossil fuels that will eventually lead to a rapid rise in non-carbon fuel such as hydrogen. UPI concludes that redesignating redundant offshore oil and gas platforms as hosts for wind-powered generators that in turn convert that energy to hydrogen and pump it ashore has the greatest opportunity for beneficial environmental impact. By following this model, some new energy providers could not only become carbon neutral but could actually become carbon negative.