R&D program seeks to reduce methane emissions

Twelve multi-year research projects under way

Bill Pike

KeyLogic Inc./US Department of Energy

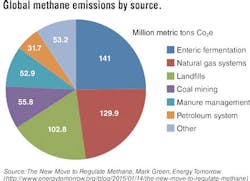

The emission of methane from oil and gas operations has become the topic of considerable debate of late. Methane is a “primary constituent of produced natural gas and a greenhouse gas (GHG) with a global warming potential of over 20 times that of carbon dioxide,” according to the SPE paper “Designing the Ideal Offshore Platform: Methane Mitigation Strategy” (Bylin, et.al., SPE 126964, 2010). Taken together, methane emissions from oil and gas represent a major portion of all methane emissions worldwide.

In addition to being a major GHG, emitted methane has considerable value. Annual methane emissions from the global oil and gas industry are equivalent (in 2010) to 94 bcm, or $10 to $23 billion worth of natural gas lost to the atmosphere, according to the SPE paper.

In the offshore industry, methane emissions mirror global emissions. In 2010, offshore production of oil and natural gas made up 9% of methane emissions from the US production sector and 6% of total methane emissions, accounting for 41% of total methane emissions in the petroleum sector. The emissions come from a number of different sources, including drilling and production platforms, service fleets and pipelines (both offshore and onshore).

In response to the growing methane emissions debate in the US, the Environmental Protection Agency (EPA) issued the first-ever standards to cut methane emissions from the oil and gas sector in May 2016, after having received some 900,000 comments on an August 2015 methane emissions reduction proposal. The standards, and associated regulations, are predicted to reduce 510,000 short tons of methane in 2025, according to the EPA.

At the same time, an Interagency Methane Strategy was also initiated by the Obama administration under the Climate Action Plan. Under that strategy, the US Department of Energy (DOE) was enlisted to “continue to conduct research and analysis to help improve our ability to measure methane emissions and advance technologies and practices that will enable cost-effective emissions reductions,” as noted by then US Energy Secretary Ernest Moniz.

The result was the September 2016 announcement by DOE of a natural gas infrastructure R&D program to enhance operational efficiency while reducing methane emissions. Under the program, $13 million of total funding will be awarded to 12 multi-year research projects intended to develop cost efficient and effective ways to mitigate methane emissions from natural gas pipeline and storage infrastructure. The research will also look to better quantify the sources, volumes, and rates of methane emissions. This new initiative by the Office of Fossil Energy builds upon the President’s Climate Action Plan Strategy to Reduce Methane Emissions.

Seven of these newly selected projects will be mitigation-focused research efforts that will work on developing a suite of natural gas leak reduction technologies. These research initiatives will help to develop, modify, and evaluate tools and technologies for methane mitigation beyond a proof of concept and eventually have the potential to be commercialized in the near future.

The remaining five projects will advance methane emission quantification research that is intended to better measure and understand methane emissions derived from the natural gas supply chain.

The following seven projects represent the start of DOE’s Methane Emissions Mitigation from Midstream Infrastructure research. These detection and mitigation projects may also be applied to production facilities and are applicable to both onshore and offshore operations.

Oceanit (Honolulu, Hawaii).Oceanit will develop EverPel, a multi-functional coating to prevent corrosion and deposits that would require pipeline refurbishment and repair, which leads to methane emissions.

Southwest Research Institute (San Antonio, Texas).Southwest Research Institute will develop and demonstrate an optical-based methane leak detection system for midstream infrastructures.

PPG Industries, Inc. (Allison Park, Pennsylvania).PPG Industries, Inc., GTI, and RTI International will develop and demonstrate three technology platforms which will be combined as a system to provide remote monitoring of natural gas pipeline conditions, and early detection of factors leading to a potential for unintended methane release.

Princeton University (Princeton, New Jersey).Princeton University, along with American Aerospace Advisors, Inc., will develop and deploy new advances in chirped laser dispersion spectroscopy (CLaDS) to make an airborne-based sensor for remote detection of methane leaks from pipelines, compressor stations, and other midstream infrastructure. The technology would use a range-resolved, integrated-path spectroscopic technique to remotely identify leaks along pipelines and other related facilities. The primary objective is to develop, test, and field demonstrate the heterodyne-enhanced chirped modulated CLaDS (HE-CM-CLaDS) system for the ability to perform measurements with low light returns, immunity of the measured signal to back-scattered light intensity fluctuations and high linearity and extended dynamic range of concentration detection.

Southwest Research Institute.SwRI, along with Next Seal AB, and Williams Pipeline will develop a seal design for reciprocating compressor piston rods that mitigates the highest contributor to methane emissions from midstream machinery. The primary objective is to design, manufacture, and test a liquid seal in a full-scale setting to demonstrate the operability of the seal, verify the performance of components, and demonstrate the potential for producing a seal that reduces methane emissions with minimal wear to the seal.

Gas Technology Institute (Des Plaines, Illinois).GTI and Jet Propulsion Laboratory will develop and test an integrated Thermoelectric Generator/burner system in a field pilot for oil and gas field operations. The system will substitute air instead of natural gas as the operating fluid for pneumatic controllers, resulting in energy recovery and reduced greenhouse gas emissions.

University of Pittsburgh (Pittsburgh, Pennsylvania). The University of Pittsburgh and Corning Inc. will develop an advanced distributed optical fiber technology optimized for natural gas infrastructure monitoring which could have significant impacts on distributed fiber sensing technology and its applications in the energy industry.

In addition, DOE has selected five projects which will kick off DOE Methane Emissions Quantification research. These are described below.

Gas Technology Institute.GTI, along with AECOM, GHD Services, Inc., and WSU Laboratory for Atmospheric Research Laboratory will conduct field campaigns to measure methane emissions from new and vintage plastic, plastic lined steel, and cast iron pipes as well as from industrial meters. The primary objective is to collect information on parameters that would allow further classification of pipeline and meter emission categories to improve the Environmental Protection Agency’s US Greenhouse Gas Inventory (GHGI) and help operators prioritize the repair of leaks to maximize reduction of methane emissions.

Colorado State University (Fort Collins, Colorado). The University of Colorado and AECOM will: (1) develop nationally-representative, activity-weighted, methane emission factors for each type of principal equipment located at typical gathering compressor stations suitable for use in EPA’s GHGI; (2) develop estimates of episodic emissions; and (3) test new methods to characterize intermittent device emissions. The primary objectives include conducting a field measurement campaign, consolidating and publishing measurement results, developing a national model of gathering operations, and publishing a national model of methane emissions, including activity-weighted emission factors.

GSI Environmental Inc. (Houston, Texas).GSI Environmental Inc., along with Utah State University, Colorado State University, and Houston Advanced Research Center, will carry out field investigation activities at the Clay Basin, Utah, underground natural gas storage facility, which ranks among the top 20 largest gas storage facilities in the US The primary objective is to employ a novel combination of complementary measurement methods and technologies to detect and accurately quantify average annual methane emissions from an underground natural gas storage facility, including from aboveground equipment leaks and seepage at the ground surface from underground leaks.

GSI Environmental Inc. (Houston, Texas).GSI Environmental Inc., along with Utah State University and Houston Advanced Research Center, will employ a step-wise process to improve the accuracy of methane emissions reported in EPA’s GHGI. GSI will integrate a novel data visualization package that digitally overlays methane concentrations and rates over time with three dimensional smart maps of the site.

University of Colorado Boulder (Boulder, Colorado).University of Colorado Boulder, along with NIST, University of California-Davis, and Scientific Aviation, will collect ground-based regional scale measurements and aircraft measurements in order to estimate emissions across the underground storage sector. The project will consist of multi-month deployments of a ground based dual frequency comb spectrometer in conjunction with multiple, focused aircraft mass balance flights at oil and natural gas storage facilities.

The Office of Fossil Energy funds research, development and demonstration projects to reduce the risk and cost of advanced carbon technologies and further the sustainable use of the Nation’s fossil resources. To learn more about the programs within the Office of Fossil Energy, visitwww.energy.gov/fe/ or sign up for FE news announcements at http://energy.gov/fe/register-fossil-energy-newsalerts.