New leak detection technology shows promise in a range of applications

It is widely recognized that 30-45% of all active wells globally suffer from integrity issues1 with over 30% exhibiting sustained annulus pressure which rebuilds after it is bled off2 – a common indicator of a persistent leak route from the reservoir. Other integrity issues can include barrier or valve malfunction or corrosion failure of completion strings, conductors or casing3, which can result in hydrocarbon migration within the completion or, in the worst case, escape to the environment.

As the market has evolved and well stock has aged, operators have often acquired or inherited wells without historical data. Added to this, the pressure on operators to reduce the cost burden, protect the environment and pro-actively manage their assets to avoid unnecessary or prolonged downtime, the demand for detailed, quantitative evaluation of well risk has increased. Integrity surveys are now a high priority for all operators, including those with already well documented, historical data. Ensuring good well integrity sits at the core of responsible management, whether the aim is enhancing production, extending life or reducing the financial burden.

The cost of well workovers and loss of production caused by integrity issues is huge. Worldwide it may account for as many as half of all well shut-ins and nearly half of all workovers in mature fields4. The cost to the oil and gas industry, in terms of lost production alone, has been estimated at $1.09 billion/day (2015)5.

Traditional well surveys

Downhole surveillance provides the crucial first step in a better understanding of well integrity, locating points of fluid movement and identifying where and what type of remediation work will be effective. Pro-actively gathering this intelligence ensures long-term efficiency and cost reduction, but there have historically been barriers to its uptake. This has mainly been due to the cost, time and risk presented by performing the survey itself.

Traditionally, leak detection has been performed using Spectral Noise Logging (SNL) tools conveyed on wireline for real-time data, or slickline in memory mode. The drawbacks of this method are derived from the limitations of the system, the use of point measurements and limited data at surface. The movement of the tool within the wellbore creates significant ‘road noise’ which can mask the acoustic signal of the leak. To overcome this, the SNL tool must be stationary and therefore an initial pass or log is desirable, but not always possible, to identify likely locations for the leak followed by a high number of tool stations. When deployed on slickline in memory mode, the leak detection is performed blind with data only recovered when the tool is retrieved. Even when deployed on wireline, only a fraction of the acoustic signal can be transmitted via the copper wires. The result is long survey times and limited ability to ensure that the leak location has been detected prior to rigging down.

In terms of timescales, this dedicated wireline intervention program involves 3-6 hours to rig up at the wellsite; between 18-48 hours to perform the survey; 3-6 hours for rig down and demobilization; and over a week for full interpretation of the data.

More recently, leak detection surveys have been performed with fiber-enabled slickline6. These systems use a fiber-in-metal-tube (FIMT) system whereby the optical fibers are encapsulated within a 1/8-in. metal tube that can be deployed as slickline or within a coiled tubing system.

Using both single mode and multi-mode fibers for distributed temperature sensing (DTS) and distributed acoustic sensing (DAS), the entire wellbore can be logged simultaneously with the FIMT static in the wellbore. This solution requires similar surface equipment as wireline to deploy, with similar associated timescales, but enables the leak detection survey to be completed more quickly. Fiber also provides integrity information over greater depths and as a function of time, to detect direction, velocity and periodic issues. Further to this, the data is collected at surface and available for immediate analysis while the FIMT is still in the well. FIMT does not provide the same acoustic sensitivity as contemporary spectral noise logs and requires capital investment in a specialist cable, so while is has proven effective in many applications, uptake to date has been limited.

Bare fiber advantages

Overcoming the limitations of wireline logging and FIMT surveys is possible using a disposable ‘FiberLine Intervention’ (FLI) system. FLI was introduced by UK-headquartered company Well-SENSE in 2016 and has been commercially deployed around the world with success, in a range of survey applications and well types. The system provides all the advantages of distributed fiber-optic sensing, but with higher acoustic and thermal sensitivity, leading to a higher-quality image and more detailed insights into the well and surrounding environment. This quality data is combined with improved simplicity, time, cost and space savings when compared to wireline or FIMT techniques.

The technology is a complete intervention and surveying system, requiring no additional well control or wireline equipment. This reduces the wellsite rig-up footprint by 95% and the time to rig up by 50%. Surveys are performed by a single engineer offline, allowing other operations to continue as planned.

Uniquely, the system deploys bare fiber into the well from a small, weighted probe, both of which are disposable at the end of the survey. With very little surface hardware, offshore rig-up and deployment to depth is often complete in under two hours. Coupled with the efficiency of a distributed fiber-optic sensing survey, the time savings mean that multiple wells can be surveyed within days. Batch surveys provide valuable insights at a greatly reduced cost, ahead of planned interventions, allowing operators to precisely plan and optimize their campaigns.

A closer look

FiberLine Intervention is a standalone system comprising a single use fiber deployment probe, pressure-controlled release assembly, hand pump and fiber-optic data acquisition system. The probe is available in 1,625-in., 2.00-in. or 2.75-in. OD versions and may be configured with one or more spools of bare optical fiber, up to 25,000 ft (7,620 m) in length. Both single-mode or multimode fiber can be accommodated with the most common probe configurations, using both for simultaneous DAS and DTS acquisition. Weighing less than 16 lb (7.2kg) and measuring up to 5 ft (1.5 m) in length, the probe is lightweight and easily handled around the wellsite, with a single engineer able to run the entire operation. The complete loadout including pressure control equipment (PCE) can be packed in a half height eight-foot container, saving deck space.

Unlike conventional intervention services, FLI does not feed cable into the well. Instead, the fibers are held at a pre-determined point at the top of the PCE and, as the probe free-falls into the well, the bare fibers are paid out behind, adhering to the wall of the wellbore for continuous, real-time, depth-specific logging. The probe can also be pumped into the well to access highly deviated and horizontal wellbores.

Offshore case study

The FiberLine Intervention system was recently selected by a leading international operator to investigate sustained annulus pressure in an offshore well. Located in the North Sea, the well had been in production since 1982 before being released for abandonment in 2019. In preparation for abandonment, a deep-set plug was set around 9,000 ft before cutting the tubing above this to circulate liquids into the well. Fluid returns could not be established and a shallow set plug was deployed. Following pre-abandonment operations, the operator had observed pressure in the A-annulus building-up from 0 psi to 1,070 psi and it was suspected that the gas lift valve below the deep-set plug had been washed out. However, upon opening the well, a pressure of 943 psi was observed in the tubing, indicating either a shallow leak path or failure of the shallow set plug.

The objective for FLI was to determine the leak point to enable barriers to be re-established, by monitoring the real-time DAS and DTS profiles, while the B-annulus pressure was being bled down. Fluid and gas movement will generate sound energy, with high frequencies attenuated more quickly than low frequencies. The change in frequency indicates the depth origin of the leak in relative distance from the fiber sensor. Fluid or gas movement can also cause localized changes in temperature which can be used to identify the leak point, both in terms of depth but also in terms of entry and exit points. A tubing leak, for example, could generate a change in localized temperature next to the fiber, but an annulus leak may not, as there is a physical barrier between them, so this information can determine the point of origin.

Two disposable distributed acoustic and temperature sensing fibers were deployed into the well via a 2¾-in. diameter probe to a total depth of 8,850 ft. The probe reached total depth 16 minutes after being launched at surface and the gas/liquid interface was identified at 3,900 ft by a change in the descent velocity of the probe and verified with the acoustic coupling signature. Once the ambient acoustics from deployment had diminished, then baseline DAS and DTS logs were taken as a reference point. Next the leak was induced using differential pressure, by bleeding off from the B-annulus valve. The leak detection activity was completed 25 minutes later having captured fluid movement from a source at the top of the 7-5/8-in. liner, moving both up the well towards a side pocket mandrel, and down to a milled window.

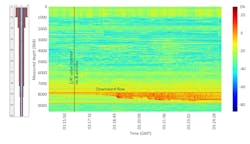

Figure 1 shows the baseline acoustic log and the effect of opening the B-annulus valve over the following 10 minutes. There is an obvious and almost immediate acoustic event starting at a depth of 7,960ft, with downward progressing flow over time.

Taking a closer look at the acoustic anomaly in Figure 2, a flow front is observed travelling both up and down the completion at a velocity of approximately 2.2 ft/s. The upward flow rises to the top of a 7-5/8-in. liner, at 7,912 ft, whilst the downward flow travels to a depth of 8,200ft which coincides with the top of a milled window in the 9-5/8-in. casing. At this point the flow front accelerates to 20 ft/s with increased acoustic energy, before returning to a flow rate of 2.2 ft/s at 8,360 ft and continuing down the wellbore to a depth of circa 8,660 ft.

The distributed temperature survey in Figure 3 shows the thermal gradient of the well. Throughout the survey there were no obvious thermal responses associated with the pressure bleed down of the B-annulus, so this indicated no leak path through the tubing, which is very useful information to support the findings from the DAS data.

After the bleed down of the B-annulus, there was no further evidence of flow and the acoustic response was very similar to the original baseline. This established that once the pressure differential had diminished the leak was no longer present. It also confirmed the leak was at a single point in the well and there were no other leak paths present within the wellbore or completion. The survey data allowed the operator to make well-informed and efficient remediation decisions prior to well abandonment.

Value to operators

Compared to other surveillance solutions, FLI has been shown to be the lowest cost, highest quality and finest sensitivity option, with the smallest wellsite footprint and the fastest time to rig-up and down and perform the well survey. The rapid and compact offline solution is also highly compatible with batch operations, enabling multiple wells to be assessed, achieving even greater savings and added value.

In mature wells, cost is a critical factor in maximizing late-life production, reducing the burden of ongoing integrity challenges and remediation work, and final decommissioning liabilities. In this situation, Fiberline Intervention provides the best opportunity to assess the well risk and optimize value. It enables good investment decisions and ensures that downhole operations are well planned and keenly targeted.