Flow assurance methods reflect increasing production challenges

Bob Carter

Mentor Subsea Technology Services Inc.

Changes in field development and produc-tion requirements that continue to place new demands on the industry. The past 12 months have seen a continued emphasis on flow assurance issues as operators around the world seek to enhance the potential of acreage already in their portfolios or plan for new developments under more difficult conditions.

The general concept of flow assurance relates to delivery of a hydrocarbon from its reservoir to a preliminary processing facility where it is prepared for subsequent shipment to a refinery for final processing and eventual sale. Hydrates and paraffin are probably the two most readily identified flow assurance phenomena. In addition to those, flow assurance, on a broader scale, includes asphaltenes or other precipitants or flocculants, corrosion, emulsions, slugging, and any other condition that disrupts or inhibits hydrocarbon flow between the reservoir and initial processing facility. All the aspects of flow assurance become more critical, and their control more important, in deepwater and more remote locales. Accurate fluid characteristics are fundamental to system optimization as the costs associated with field productivity increase both for avoidance and for remediation.

Flow assurance issues

In general, flow assurance problems are avoided as much as possible or remediated after their occurrence. Avoidance is achieved through chemical or mechanical means, and in the case of hydrates and paraffin, control is achieved by maintaining flowline temperatures and pressures in a "safe" zone. Chemicals are also used, generally glycol or methanol, but this type of "active" control is more complicated than "passive" temperature control achieved through insulation.

Pressure is less easily controlled, but the use of subsea booster pumps is growing and may provide some flow assurance benefits, in addition to productivity improvements. However, if a production line becomes restricted or completely blocked, remedial measures must be used to reestablish flow. Remediation includes flowline depressurization to remove a hydrate blockage. This may be avoided by selecting an optimized flowline route and bathymetry but is not always possible. Paraffin restrictions are generally addressed by pigging, using a "round trip" dual-flowline routing.

Technology

Avoidance measures for flow assurance problems may include the use of riser-base gas lift to reduce or eliminate severe slugging. This technique is currently in use, as are the more common subsea and topsides slug catchers. A developing method for pressure maint- enance is to boost well bore or flowline pressure using subsea booster pumps driven either electrically or hydraulically using energy from water injection or gas injection lines to drive the pump.

The use of single flowlines in conjunction with a subsea pig launcher is a possibility as subsea pig launchers expand in usage and acceptance. Pressure and temperature monitoring systems increase the data available for an operator to use in evaluating system performance and schedule pigging runs or chemical dosing requirements.

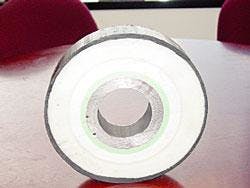

As noted previously, temperature and pressure are two prime constituents of flow assurance avoidance and remediation, and of the two, temperature control is the easier to influence, although chemicals may be used either independently or in conjunction with insulation to alter the fluid's characteristics and tendency to foul the flowlines. Temperature control in the wellbore may also be an issue in system performance, and the use of vacuum insulated tubing is a solution to be considered.

The development of reserves in deeper waters requires that new testing programs address mechanical and thermal performance to identify potential issues with installability and suitability for long-term service. This is increasingly important for production risers as water depths continue to increase and thermal performance must be matched by long-term mechanical integrity of the insulated piping system. Deepwater issues to consider include:

- Collapse resistance of insulating materials and the flowline or riser

- Joule-Thompson cooling effects from gas expansion in the riser that can affect steady-state flowing temperatures and cause hy-drate formation

- The use of buoyancy as insulation.

New solutions are emerging to deal with the growing challenges of deepwater and related problems.