ESPs used to prolong reservoir depressurization

John Blanksby

Steve Hicking

Shell UK Ltd.

William Milne

Baker Hughes Centrilift

The installation of electrical submersible pumps (ESPs) to back-produce water from the reservoir in the Brent field in the Northern North Sea is extending the life of the field. ESPs have been deployed with some success to prolong reservoir depressurization in order to replenish the gas cap for subsequent production. This is the first offshore application of ESPs for this purpose and differs from water production from aquifer wells for reinjection purposes.

The Brent field lies in the northern part of the UK sector of the North Sea, 110 mi northeast of Shetland. Shell UK Ltd. operates the field on behalf of the joint venture with Esso Exploration and Production UK Ltd.

The field was brought onstream in 1976 and will be operating, as of next year, 30 years. During this time, it has changed from being predominantly an oil producer with associated gas sales to being a gas producer with oil production at the tail end. Gas exports began with the commissioning of the FLAGS pipeline in 1982.

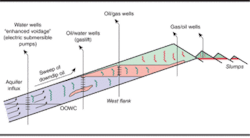

Brent is currently being depleted as part of a depressurization process. Depressurization is controlled not only by production from oil and gas wells but also by the addition of enhanced voidage (EV) wells. These EV wells produce water to accelerate depressurization, allowing the gas cap to expand, and ultimately reach a lower abandonment pressure. To date, it is the largest offshore reservoir depressurization scheme in the world.

During the 1990s, the Brent field underwent redevelopment to prepare it for the changing depletion strategy. After 17 years of water injection to maintain the reservoir at a constant pressure, field-wide water injection ceased during 1997. During this period, 2 bbl of water had been injected for every bbl of oil produced.

A total of 2.8 Bbbl have been injected since 1980. Now, the reservoir is being depressurized as part of the long-term field development. Depressurization began with shutting down water injection when the reservoir pressure was at 5,000 psi.

Offshore infrastructure comprises four platforms, one of which (Alpha) has been adapted to “lighthouse mode” and is tied back, remotely operated from an adjacent installation. The three remaining platforms (Bravo, Charlie, Delta) have been designated for long-term field development (LTFD). Production is expected to continue beyond 2010. The EV project represents the final phase of the LTFD and is also termed deep depressurization.

The objective of depressurization is to release solution gas from both residual and trapped oil that is uneconomic to drill or has been bypassed. The liberated gas migrates up-dip to replenish the gas cap. This migration increases gas recovery and improves lift efficiency, allowing a lower final abandonment pressure of crestal wells.

The quantity of gas liberated by a volume of EV water is termed voidage ratio and is not a constant value. It is time-dependent, increasing to a maximum value before declining with time.

The producing formations are Brent and Statfjord reservoirs of the Middle Jurassic age.

The Brent reservoir pressure has been declining at an average 600 psi/yr from an initial pressure of 5,700 to currently 1,800 psi (datum 8,700 ft TVD-ss). Similarly, the deeper Statfjord reservoir pressure is declining at an average 600 psi/yr from an initial pressure of 6,130 psi (datum 9,400 ft TVD-ss) to its current 2,400 psi.

Sensitivity to well productivity index considered the range 10-150 bpd/psi. ESP modeling showed that sensitivity to productivity index (PI) was acute when the PI fell below 50 bpd/psi. A suite of pumps was required to track reservoir static bottomhole pressure (SBHP) in line with the expected steep decline curve.

Field-wide lift strategy

The reservoir has been successfully produced (and depressurized) using gas-lift to maintain production of crestal producers. As reservoir pressure declines, gas-lift becomes less efficient, wherein these wells will eventually die.

Producing water from dedicated EV wells lowers the reservoir pressure and releases incremental solution gas from the residual oil. The gas migrates to the crestal producer wells and is produced approximately a year later. EV wells are targeted to counteract the influx of water from the aquifer and drive deep depressurization to release solution gas. This helps to sustain the high gas-to-liquid (GTL) ratio crestal wells, necessary to continue producing the incremental solution gas released from depressurization.

ESPs are required to maintain the momentum of depressurization and to take the reservoir down to its planned abandonment pressure. Current gas-lift methods, including deep gas-lift, would result in field abandonment at 1,500 psi, whereas with ESPs a cut-off pressure of 1,200 psi is feasible. At present there is no alternative to ESPs to achieve depressurization below 1,500 psi.

The project has undergone considerable evolution since the original Redevelopment Plan was submitted in 1992. Currently, the number of wells has been revised to 12. The ratio of wells targeted in the Brent vs. Statfjord is 2 to1.

Deployment of ESPs began during 1999-2000 with the commissioning of a single unit on each platform. A two-year hiatus ensued due to intense focus on drilling oil and gas infill wells and better than expected reservoir depressurization. In 2001, a predicted shortfall of wet gas production gave the project renewed impetus, and ESP installations resumed.

Further installations began late 2003 to project completion in 2005. Consequently, project execution has been undertaken in three phases, where each well is expected to produce approximately 10 MMbbl of water, liberating about 10 bcf of gas.

The EV design provides high-productivity wells capable of large offtake rates. Project economics require healthy run-lives. Installing sand control and performing regular scale inhibitor squeeze campaigns mitigated the risks of sand production and scaling. Flow-wetted components use corrosion resistant alloy to provide long-term integrity and reuse capability. Tubing size is maximized to allow optimum utilization of ESP horsepower.

Topside facilities

EV fluids were expected to be similar to carbonated mineral water. Production would be via dedicated manifold and degassers with marine disposal via dump caisson. Entrained gas would be recovered by the LP compression system.

Instead, the potential for significant hydrocarbon in EV fluids and available usage in the hydrocarbon production system favored using the existing LP production system. New flowline, production choke, and manifold isolation valve required for each EV well are constructed from duplex stainless steel and connect to the existing LP manifold.

The switchgear is housed in self-contained modules, pre-commissioned onshore, before being retrofitted offshore. Switchgear modules on Bravo and Delta platforms have the capacity for 10 ESPs each; Charlie platform has a mini-module with switchgear for two ESPs. A 60-Hz fixed-speed system with HV soft-starters was selected due to space and cost constraints plus the design basis of produced fluid composition did not require the increased flexibility afforded by variable speed drives.

Typically, EV wells produce 100% water with trace oil content and some free gas. A strategy of targeting mid-dip wells to co-produce oil with water proved to be short-lived. Wells drilled either found no oil or encountered un-depleted formations with high gas-to-oil ratios compromising ESP operability and reliability.

Drilling a 12 1/4-in. sidetracks through pre-existing 13 3/8-in. casings meant that 9 5/8-in. 80-ksi production casing was the logical choice. New EV wells provided an opportunity for full life-cycle (15 year) corrosion integrity, particularly to protect against the higher fluid temperatures expected across the 725 motor section. The lowermost 500 ft of the new 9 5/8-in. production casing string was specified as 13% chrome casing.

The lower completion comprises the sand-face completion hung off a sump packer with 7-in. liner and incorporates mechanical fluid loss devices to enable completion and workover.

Sand exclusion is required as reservoir depressurization will inevitably lead to sand failure. Predictions also indicated that limiting drawdown would have little effect since numerous intervals within the reservoirs are vulnerable to failure. The sand screens used for exclusion are fabricated from Alloy 825 with 304SS and components. A fluid loss control valve is run as an integral part of the sand screens. It is a ‘one-shot’ device installed between the hang-off packer and screens, providing a barrier to allow the upper completion to be run.

The completion comprises two sections, upper and lower, where the function of the lower completion is to allow isolation of the upper wellbore from the open-hole reservoir section. It also provides an extra barrier above the open reservoir while running the upper completion. Additionally, the lower completion is attached to the upper completion, which comprises the ESP system, production packer, downhole safety valve, tubing, and tubing hanger.

The horizontal tree was selected to facilitate replacement workover. The tree is 5,000 psi rated and flow-wetted surfaces of the tree, tubing hanger, and production choke are either clad with Inconel 625 or manufactured from Inconel 718.

ESP design

The ESP system was specified to meet the requirements of flow rate, pressure/temperature, and fluid. The flow rate system selected was based on delivering 500 kb/d of water production across the field using 18 ESPs. This translated into a system capable of being operated at a maximum of 43 kb/d (at 60 Hz) assuming a best efficiency point of 35 kb/d.

The pressure/temperature were estimated to result in a tubing head pressure of ± 5 barg and a reservoir temperature of 210o F determined from the existing Brent BOD dataset.

The GLR of the fluid initially was estimated to be 1-15 cf/bbl, but after a better understanding of solution gas, production from swept or un-swept zones (i.e. above or below the original oil-water contact) could range from 15-500 cf/bbl. Testing was carried out at Centrilift’s R&D facility (Claremore, Okla.) on the 675 H series pump. The design incorporates tungsten carbide thrust and radial support in every stage for abrasion resistance. A floating-stage pump was selected because the high hydraulic thrust developed would exceed the single thrust bearing capability of a fixed-stage (compression) pump. The final outcome of extensive testing with different permutations resulted in an HC35000 tandem pump (2 x 20-stage) with tungsten carbide inserts (1:1 configuration) for abrasion resistance.

Once the design had been finalized, factory acceptance tests were conducted to prove pump performance, following which a site integration test was carried out to confirm system integrity.

The 9 5/8-in. casing allowed the maximum horsepower units to be used for the application. Maximum horsepower is limited by the shaft strength of the 675 H series pumps (6.75-in. OD), which have a capacity of 1,250 hp (Inconel 718 shaft with involute spline) and 43,000 b/d at 60 Hz. This also allows use of a 725 tandem motor with specifications of: 1,250 hp, 4500V, 161A, 60 Hz, 250°F. The Brent motors are rated to 1,500 hp (100°F) and de-rated by the vendor to 1,250 hp (250°F). Shaft material is K500 Monel.

Initially a tandem HC35000 (40-stage) pump was installed, giving way to the triple-tandem HC27000 (60-stage) pump and HC19000 (initially 84-stage, now 87-stage) to compensate for the rapidly declining reservoir pressure.

To improve the heat resilience of the ESP system, elastomers and other materials have been revised to a higher temperature specification: seal section bag elastomer from Nitrile to Aflas; motor interconnector insulators from Torlon to PEEK, and motor bushings from brass to tungsten carbide.

The slippage in project implementation occurred for several reasons:

- Favorable reservoir performance, through having a weaker aquifer and lower critical gas saturation than predicted, allowed voidage through conventional oil and gas well production to be effective;

- Successful gas-lift project (incorporating deep gas-lift) enabled voidage to continue with conventional wells to lower reservoir pressures; and

- New drill infield oil and gas wells with higher economic value prioritized activities away from EV (value of early EV was reduced due to good reservoir depressurization performance). Project deferral rendered some of the early planned units redundant.

Acknowledgments

The authors would like to thank Shell UK Ltd. and Esso Exploration and Production UK Ltd. for permission to publish this paper. Thanks are also due to the EV project team, the ESP task force, and both development and well engineering teams within Brent for their respective contributions. Particular thanks are due to Alastair Simpson (Triangle Engineering) and Neil Griffiths (Shell International Exploration and Production) for advice and assistance provided in preparing this paper.

Editors Note: This is a summary of the SPE 96797 paper presented at Offshore Europe 2005.