Unlimited depth applications predicted for lower-cost Spar floaters

Oil prices were less than $20/bbl until sometime in July 1999. The industry was much slower than expected to respond with capital expenditures. Now, in 3Q, 2000, expenditures appear to be accelerating amid concerns about insufficient human resources to execute planned projects. Apparently, there are still reservations about the price of oil remaining at a level sufficient to sustain high-cost deepwater projects.

Unquestionably, the petroleum industry tracks the global economy, with some areas more influential than others. Now that Southeast Asia economy appears to be recovering, this should be a positive sign for the petroleum industry. There are 3.5 billion people in Southeast Asia with a per capita oil consumption of about 1 bbl; by comparison, US per capita consumption is 33 bbl/person/yr. China continues to have a net population growth of 12 million people per year - the equivalent of two Norways per year. We will always experience price cycles, but it is hard to visualize any scenario that would keep prices "low," indefinitely.

Ultra-deepwater

The single, most promising growth area for the petroleum industry is deep- and ultra-deepwater on a global scale. For this discussion, let's define these terms as 1,000-5,000 ft and beyond 5,000 ft, respectively (the MMS has defined ultra-deepwater as 5,250 ft). Technology has progressed so rapidly that "deepwater" has almost become routine. "Ultra-deep" is receiving attention due to the need to fill some technology gaps and to reduce costs, while never compromising safety and environmental issues.

The US Gulf of Mexico is the most active area in the world for ultra-deepwater (UDW) opportunities. Table 1 summarizes the number of ultra deepwater leases in the US Gulf during the past three years. Recall that leases in 2,624 ft (800 meters) and deeper have a 10-year term.

The regional table indicates that there is moderate activity in ultra-deepwater (UDW) and lease sales data imply there is an abundance of leases that must be drilled or relinquished. The objective is to find oil and gas in commercial quantities. This brings up the crux of the matter - the definition of "commercial quantities." There are too many variables to discuss, but having low cost reliable floating "real estate" is quite often the consideration, which makes a discovery a commercial success. One proven and cost-effective floater is the Spar.

Spar producer

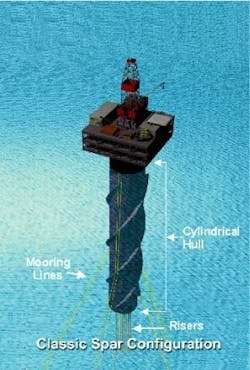

The Spar producer is a moored platform characterized by a relatively long cylindrical shape (Fig.1). It floats upright, partially extending above the water level, thereby providing a place for affixing the deck (s) for drilling and/or facilities and/or dry trees, or oil storage, and other function. The upper end of the long cylindrical structure incorporates a plurality of watertight compartments, which provide the buoyancy.

The lower part is filled with water, functioning as a means to provide/adjust ballast. The net result is that the Spar hull has a relatively deep draft with a center of buoyancy considerably above the center of gravity. This characteristic of the Spar configuration makes it a more stable platform than any other floating system.

Drilling risers and/or production risers, and/or flowline-pipeline risers can be placed in the center of the Spar (Fig. 1). This provides a protected area for the risers and facilitates the use of multiple risers, especially when considering the Spar's slight motion. The Spar also provides cost effective oil storage facilities. Since the Spar is moored (lines versus tendons), it can easily be used in water depths to 10,000 ft.

The Spar is a relatively simple and field-proven design for deepwater applications. To date, there have been three actual installations, with an additional two Spars under construction (Table 3). Figure 2 shows the Spars installed and under construction in a graphic format.

The Spar designed for the deepest water depth to date is 5,400 FSW. However, Aker has done considerable research to verify that the Spar is relatively insensitive to water depths. It can easily (and economically) be applied in water depths to 10,000 FSW or greater.

Conversely, a TLP, for example, is limited due to thickness/diameter ratio of the tendons to accommodate the collapse pressure and tensile load requirements in deepwater. While numerous other factors enter into the TLP tendon "equations," which may be solvable from a pure engineering viewpoint, the cost of the tendons appear to become prohibitive. Mooring lines on a Spar are much more economical and represent a small portion of the overall investment.

As alluded to above, the Spar is successful due to its very limited motion characteristics - stability due to its basic configuration of a long cylindrical structure. These positive characteristics, including drilling riser, production riser, and pipeline riser designs have been verified by the approximate four years of service of the Oryx-Kerr McGee Neptune Spar. It is noteworthy that the Neptune Spar successfully weathered two hurricanes. Hurricanes Earl and Georges in September 1998 subjected the Spar to 78-knot winds and 36-ft significant waves.

Deep applications

There is no doubt the industry is rapidly moving into ultra-deepwater. This imposes an increasing emphasis for further reducing the cost of Spars. Two approaches, somewhat interdependent, are aggressively being studied and tested by the research and development group within Aker Maritime:

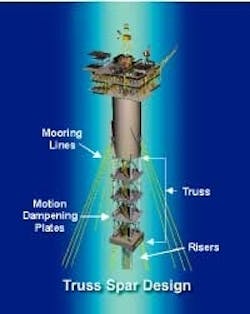

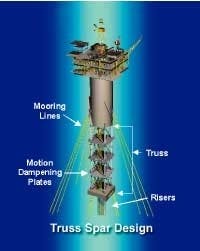

- The first is to take "lessons learned" by simplifying the Spar design and reducing the weight and cost. This has been accomplished primarily by replacing the lower cylindrical end of the Spar with a truss structural configuration (Fig. 3). By using large horizontal flat plate-like sections in up to five locations in the truss structure, the motion of the Spar can be dramatically dampened, further improving the already superior motion characteristics. However, the conventional design (Fig. 1) is used when oil storage is required.

- Secondly, the dampening effect of mooring line dynamics in different water depths has been analyzed. Based on "lessons learned" data, the mooring system dampening effect (reduced heave motion) becomes more beneficial as the water depth increases. This facilitates a reduction in hull length, thereby reducing fabrication cost and transportation costs. Depending on the functional requirements of the Spar (drilling/prod-uction, oil storage, etc.), some Spars can now be transported as a one-piece assembly.

While the above are two of several ways of reducing platform costs, Aker is evaluating other approaches to reducing the overall cost of using Spars. A formal business unit was organized to pursue commercial and financial innovations to achieve this objective.

One basic approach is to make Spars available on a leveraged tax lease. The intent is to create a regional hub facility for subsea tiebacks to the facility after the lease has concluded, and thus spread the capital cost and risk over a larger portfolio of fields. In this manner, the effective cost of capital to the lessee is brought close to the lessee's own internal borrowing cost.

In order to facilitate an earlier decision on leasing, an option is available to the lessee to buy into the lessor partnership two to three years into the tenure of the lease. Hence, the lease protects the operator on the low performance case, while allowing the operator to buy in on favorable terms in the high performance case. This concept has been received very favorably.

From a flexibility/scope viewpoint, the definition of a Spar can be expanded, for example, to possibly include risers and other structures. The net result can be a very substantial positive impact on cost and cash flow.

In summation, the Spar, being a field-proven floating platform can be a very cost-effective part of an ultra-deepwater field development system. Unlike alternatives, the Spar becomes economically more attractive as water depths increase.