Topsides weight control prevents project delays

New approach implemented on Delta House project

Taylor Gulotta

Audubon Engineering Solutions

Accurate prediction of topsides weight and center of gravity (CG) plays a critical role in the development of offshore production facilities. In addition to ensuring that an offshore platform remains safe and within allowable structural tolerances throughout its lifecycle, employing effective weight management practices during design, construction, and installation is essential to avoiding schedule delays, preventing cost escalation, and maximizing overall design flexibility.

Load budget definition

Collaborating with contractors and using historical benchmark data to define initial load budgets in the early planning stages of a project are keys to effective weight management. It is in the early stages where the design is not totally fixed, thus allowing for layout and equipment selection to be modified if needed. As a project progresses, the ability to influence weight and CG starts to diminish and the cost associated with making design modifications to reduce weight increases significantly.

In general, poor scope and load budget definition in front-end engineering and design will make cost estimation more difficult and increase the likelihood of running into issues during detailed design.

Early contractor involvement and load budget definition played a critical role in the successful development of LLOG Exploration Co.’s Delta House semisubmersible floating production system (FPS) in the Gulf of Mexico. In order to keep pace with the aggressive schedule to design, fabricate, and install the platform within 30 months, work on Delta House commenced before any detailed reservoir data was available. As a result, the facility had to adopt a flexible “one size fits most” design philosophy that would allow it to handle a wide range of reservoir characteristics and hydrocarbon profiles.

This made managing platform weight and CG a challenging task - one that required extreme precision and coordination between the topsides contractor, Audubon Engineering Solutions, hull designer EXMAR Offshore, and other vendors working on the project.

Audubon Engineering Solutions worked closely with EXMAR in the early design phases to establish “Not to Exceed” weight budgets for all stakeholders. CG constraints were provided by EXMAR as a result of a stability analysis on the topsides and hull structure. Vertical CG was an important variable to monitor and control as it directly impacted the overall allowable weight (the higher the CG was above the deck, the lower the allowable weight). The horizontal CG was also closely monitored due to its importance during the transit condition, when the facility was being sailed to its final location.

In order to ensure that equipment packages complied with EXMAR’s stability constraints, the importance of weight control was stressed to vendors in the very early stages of the project. This was also the case during procurement, where weight was emphasized equally with cost and schedule. Equipment vendors were provided with specifications at the bid phase, which described the format for periodic weight and CG updates, along with requirements for final weighing and CG calculations before shipment. This helped create a singular mindset for those working on Delta House that weight and CG were top priorities, which improved communication between teams and allowed Audubon Engineering Solutions to track line items more efficiently.

Weight allowances

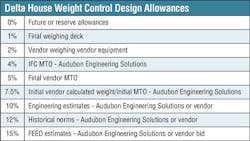

Because it is not possible to estimate the exact weight of all topsides items on an offshore facility - particularly in the early phases of the project - certain allowances should be introduced into weight and CG calculations to account for uncertainties.

Design allowances are added to individual items or groups of items based on the weight control engineer’s assessment of their weight certainty. Design allowances start as a specified percentage based on good engineering judgment, and then as the project progresses and weights become more defined, the allowances are reduced.

Using weight allowances (or contingencies) provides a certain degree of design flexibility throughout the construction process. For some facilities, the allowances may need to be included for every individual line item, whereas others may require allowances for different sections of the topsides based on each item’s individual progress. In both cases, allowing for a margin of error helps prevent delays by ensuring that the topsides do not deviate from hull stability tolerances if/when items come in heavier than originally anticipated.

In addition to the design allowances, which are applied to actual components on the platform, reserve allowances are used to account for overall design changes that may be required on the platform. Client Reserve is a weight controlled by the client and used to cover any changes to the contractual design concept. Contractor Reserve is weight controlled by one of the project contractors and is used to cover any design growth as a result of modifications made to the initial design concept.

On Delta House, for instance, Audubon Engineering Solutions initially held 300 metric tons (330 tons) in Contractor Reserve weight during the planning stages in order to account for design changes. The high figure was mainly attributable to the fact that detailed well data was unavailable at the time the hull size was chosen. If process conditions had been better defined, the reserve allowance could have been reduced.

Future Reserve is an allowance used to account for a portion of the weight budget that the client would like to hold for future production or platform improvements. On Delta House, 500 metric tons (551 tons) was held in reserve for future expansion of the topsides.

During the design of Delta House, weight reserves proved critical after pressure-volume-temperature analysis indicated an unexpectedly large volume of natural gas liquids in the reservoir. This required the addition of new processing equipment, including an 80- metric ton (88-ton) Condensate Stabilizer Skid to meet sales pipeline RVP (Reid vapor pressure) specifications and reduce liquid recycle and compression requirements.

The increase in weight was mitigated by including the Condensate Stabilizer Skid in the Future Reserve allowance. Had Audubon Engineering Solutions not included the large Contractor Reserve or Future Reserve allowances in the early stages of the project, the design change could have resulted in significant schedule delays and cost escalation.

Interface management

With hundreds of different vendors providing equipment packages, controlling topsides weight and CG on offshore facilities presents unique challenges with regards to interface management. In addition to working closely with the hull designer, the topsides weight control team is responsible for interfacing with equipment vendors, along with the client, construction teams, and inspectors in order to accurately track weight and manage design changes. Complete coordination is required to ensure that all weight items are captured and none are duplicated for interface points between hull and topsides.

Typically, the responsibility of reporting weight falls on the party that designs or procures an item. However, in situations where items span large areas of the facility (i.e., piping), it may be necessary to identify break points so that it is clear where one vendor’s reporting responsibility ends and another vendor’s responsibility begins.

While every effort should be made to weigh an equipment skid when it is fully assembled, that is not always feasible. Therefore, it is important that the weighed weight is adjusted for any post weighing changes or additions and that the reported weight reflects the true installed weight of the item.

On Delta House, Audubon Engineering Solutions required vendors to supply a list of items missing from the weighed weight, as well as the estimated weight and CG for that item. In addition, any temporary items used as shipping supports or packaging that were not present in the installed condition needed to be reported. The overall weighed weight and CG were then adjusted by adding or subtracting these items.

Piping fluid weights for multiple process conditions were evaluated by using the mass densities from the stream tables and the internal volumes of the piping and piping components as reported by the Plant Design Management System (PDMS) database. This allowed Audubon Engineering Solutions to produce a realistic fluid weight per line segment for many different cases.

PDMS also provides surface area of piping elements, which was used in combination with the weight per square foot of pipe coating and insulation. In general, coating and insulation added to 1.3% of the average bare piping weight on Delta House.

Setting sail

After the topsides has been integrated with the hull and before the platform is approved to sail, a Deadweight Survey and Lightship Experiment must be performed and witnessed by the United States Coast Guard (USCG).

The Deadweight Survey is performed to determine if all items that are to be included in the lightship weight are present and in the correct position. This is followed by the Lightship Experiment, which measures the total displacement of the hull to determine the overall platform lightship weight. The experiment consists of inclining the platform by moving weights back and forth across the deck so the extent to which the hull has listed can be quantified. The exact weight and distance that the platform has tipped is used to calculate the heeling moment. Using this information, the overall vertical CG of the platform is calculated.

USCG Marine Technical Note 04-95 gives the policy for determining when weight changes to a vessel are significant enough to warrant a new Deadweight Survey or Lightship Experiment in order to reestablish accurate lightship weight and CG. Because any modifications made to the platform will have an impact on its stability and available load capacity, keeping a detailed and accurate record of any and all weight changes is critical.

Changes to lightship weight are defined as the total of all modifications made since the last stability test or Deadweight Survey. Items can be exempted from the total if weight and CG are known exactly through actual measurements. This includes components that have a documented weight by the manufacturer, structures with detailed weight take off data, and equipment modules weighed with state-certified scales or with certified load cells witnessed by a USCG inspector.1

When the facility is in operation, every effort should be made to accurately track weight and CG of items in order to exempt as many changes as possible, thus reducing the likelihood that an additional Deadweight Survey or incline test will need to be conducted offshore. This is largely due to the inherent challenges associated with performing a Deadweight Survey or inclining experiment on a platform once it is in service.

Looking ahead

In recent years, the increased trend throughout the offshore industry toward building larger and more integrated production platforms has subsequently lead to a greater focus from regulating agencies on how operators report and manage weight and CG of their facilities.

ISO 19901-5 is the international standard that governs weight control during engineering and construction for offshore structures. A second edition of the standard is currently being drafted. Slated for implementation in 2016, it will include requirements for tracking weight and CG throughout the life of a facility.

The overall goal of the new guidance will be to standardize weight control reporting across the industry, thereby placing more pressure on operators to ensure that their offshore facilities remain safe from the beginning of the design process all the way through to platform decommissioning.

Reference

1. American Bureau of Shipping (ABS). Weight Control for Floating Offshore Installations Information Sheet.