Floating production platform construction market remains key bright spot in offshore marketplace

Editor's note: This is an extended version of the cover story that first appeared in the January-February 2024 issue of Offshore magazine. Click here to view the full issue.

By David Boggs, Energy Maritime Associates

The floating production facility construction market remains one of the brightest spots in the offshore industry today. Offshore development costs remain low, with break-evens under $35/bbl for the most robust projects. Activity levels are expected to remain high from 2024-2026 but will be challenged by capacity constraints and access to finance.

The Global Floating Production Industry Survey, now in its eleventh year, gauges the current market sentiment as well as where the industry is heading in the future. Respondents come from all areas of the industry and from all parts of the globe.

This year the sentiment is overwhelmingly positive, with 93% of respondents confident in achieving their revenue and production targets. This is a record high in the survey’s 11 years. There has been a continuing trend over the past four years. In 2021, 19% were somewhat or highly pessimistic, which declined to 8% in 2022, 5% in 2023 to 0% this year. On the other end, the number of highly optimistic responses increased dramatically from 29% to 50%. The number of slightly optimistic responses decreased slightly from 48% to 43%. Also decreasing was the percentage of those in the middle, with 7% having a neutral outlook (down from 19% last year). This overwhelmingly shows great confidence in the outlook for the offshore energy sector, with little to no expectations of a negative future.

Cost inflation

Higher prices are a certainty for 2024 according to all respondents. Increased activity, reduced competition, and general inflation continue to drive this escalation. Over two-thirds expect a 5-10% increase in capex costs, while 20% believe inflation will be more than 10%. This is a significant change from last year, when 40% of respondents believed that costs would increase by more than 10%. The number who expected prices to rise less than 5% remains essentially unchanged (13%). So there seems to be consensus that costs will continue to increase in 2024, but at a slower rate than last year.

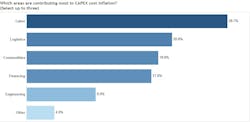

The main areas pushing cost inflation remain labor, logistics, and commodities. Last year there was more concern over commodities, while this year logistics is a greater issue. Labor continues to be the biggest expected driver of cost inflation according to 28% of respondents, up 5% from last year. Higher interest rates and financing costs remain a concern for 17%, unchanged from 2023.

Activity levels

Each year we ask respondents their views on future activity levels. Comparing last year’s expectations for 2023 with actual activity, we see that predictions were broadly in-line, with tendering and project execution even busier than predicted.

Busy times are expected for the next two years, particularly in tendering and project execution. For 2024, levels for these two areas were the highest ever recorded in the survey’s history, with 61% and 70% expecting high levels of activity for tendering and project management respectively. Activity may ease slightly in 2025, with 52% and 58% of respondents expecting high levels of activity for tendering and project management respectively.

Obstacles to growth

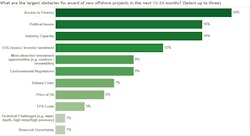

Access to finance was named as the greatest obstacle to offshore project growth, moving up from second place in 2023 and fourth place in 2022. Financing has been a growing concern, as an increasing number of banks have ceased or restricted funding for hydrocarbon developments. As a result of this and higher financing costs, more field operators have shifted their contracting approach, and contractors throughout the industry are seeking alternative sources of capital, including bonds and private equity.

Tied for second place were political issues and industry capacity. Industry capacity has been a growing concern, increasing to 16% of respondents, up from 10% last year, 7% in 2022 and 5% in 2021. Political issues had been the top issue for the past two years, but moved to second place this year. Concerns remain about global conflicts, particularly Russia-Ukraine and in the Middle East.

ESG issues/investor sentiment remained in third place this year, unchanged from 2023. Some respondents believe these are an existential threat to the industry and companies certainly factor in these issues when making investments, as seen by Shell’s exit from the UK’s Cambo development. This is another factor contributing to the difficulty in finding finance for these developments.

Environmental regulations and more attractive investment opportunities tied for fourth place. Environmental regulations slipped one place from third last year, perhaps as energy security issues and political winds have shifted. More attractive investment opportunities were ranked in sixth place in 2023. Its perception as an increased threat could be due to M&A activity, particularly in the onshore US space. There is continued interest in offshore renewables, despite reassessment and renegotiation of some projects due to unexpected cost increases.

The price of oil, which had been the main issue for seven years, has been steadily declining from second place in 2022, to fourth place in 2023, and finally to sixth place this year.

Potential bottlenecks

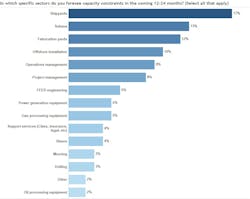

Like last year, the main issues are shipyards, fabrication yards, and offshore installation. However, this year there is even more concern from respondents about shipyards. Subsea concerns jumped up from eleventh place in 2022 to fifth place last year to second this year, reflecting a continued tightening in this sector. In addition to a busy offshore sector, there has been a huge surge in demand for renewable infrastructure and shipping, with many companies now having full orderbooks for the next three years.

Growth regions

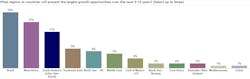

Brazil remains the top growth region again this year, as it has been since the beginning of the FPS market survey. Although Petrobras did not award any FPSO contracts in 2023, it has tenders currently in progress for five units to develop new presalt fields as well as replace aging FPSOs in the Campos basin. Independent operators are redeveloping older fields, while larger players such as Equinor and Shell are progressing new developments. EMA is tracking 26 potential projects in Brazil, which could require up to 38 floating production units.

In second place is West Africa, unchanged from the last two years. However, the number of votes increased from 16% to 21%, buoyed by the prospects of long-awaited awards in mature areas like Angola as well as new discoveries in frontier areas like Namibia.

South America (ex-Brazil) remained in third place, with a growing number of responses (up from 14% to 17%). ExxonMobil has placed orders for six FPSOs and has plans for an additional four units in Guyana (10 in total). There could be potential for double this number to develop the entire basin, which extends to neighboring Suriname.

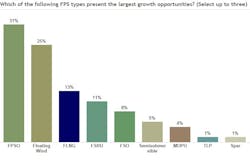

FPS types with growth potential

FPSOs remained the clear leader as the floating production system with the most promising growth potential, according to 31% of respondents. Floating wind held second position again, reflecting continued enthusiasm for renewables, despite recent setbacks due to cost overruns and supply chain constraints. FLNG remained in third place, although with less support than last year (13% of responses, down from 19% last year). Perhaps last year there was more optimism driven by the surge in LNG prices and need for energy security.

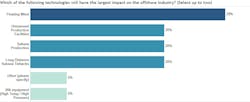

Technology game changers

This year, when we asked which type of technology will have the largest impact on the offshore industry, floating wind was again the winner by far, accounting for almost one third of the votes. While still in its infancy, there is a great deal of enthusiasm and hope for floating wind. Time will tell if it can live up to the expectations. FLNG was the top ranked technology in this survey from 2013- 2019, before dropping off the list.

This year there was a three-way tie for second place among unmanned production facilities (UPFs), subsea production, and long-distance tiebacks. Several reasons account for UPF’s popularity – the high cost of personnel as a portion of operating costs, application of digital solutions, and increasing comfort with working remotely. While unmanned fixed facilities are common, the technology is just beginning to be transferred to floaters. Even if a completely unmanned facility is not realized, reductions in personnel offshore would result in lower operating costs. In 2022, Chevron placed a $554-million order with Daewoo for the Jansz-Io production semi, which would be the first normally unmanned floating facility.

Subsea production moved up one spot with 20% of the vote. Use of this technology can reduce the topside requirements on floating facilities and keep them within existing designs. The Jansz-Io project features a $795-million subsea gas compression station, which is connected to the previously mentioned production semi.

Long-distance subsea tiebacks moved up two places this year. This technology could increase the utilization of existing facilities and follows the trend of infrastructure-led investment. Tiebacks certainly will extend the life of currently installed production units, while the impact of future requirements is yet to be seen. Some stand-alone FPS developments could be replaced by tiebacks, while an FPS hub with tieback of multiple fields could also become economic.

Measuring the supercycle

The oilfield service sector, particularly offshore, has seen strong growth starting in 2021. Deepwater drilling rates are now over $500,000/day with stacked rigs being reactivated against long term contracts. Leading shipyards have full orderbooks for at least the next three-plus years. We asked respondents how much longer this cycle will continue. The vast majority expect this growth to continue for many years to come. About 30% believe that the sector will remain busy through 2025, with 70% saying it will last through 2026 or beyond.

This is in-line with the current floating production orderbook, which stands at over 60 units. Forty percent of these are scheduled for delivery in the next year. Another 25% should be completed by 2025. New orders for large floating production units have expected lead times of three to four years.

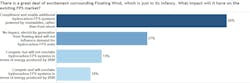

Floating wind

There continues to be a great deal of excitement regarding floating wind, with many companies looking to diversify into the renewables space. We asked about the impact of floating wind on the existing floating production sector. Would it compete or be complimentary and over what period?

Fifty percent of respondents expected floating wind to be complementary and enable new floating oil and gas units (up from 35% last year). These units could then be powered by renewable sources, rather than from shore, and reduce their carbon footprint. Plans for offshore power grids are underway in addition to stand-alone turbines for individual developments.

In a large shift from last year, only 23% (down from 43%) believed that floating wind would be competition for hydrocarbon FPS systems. This change is likely due to the large cost overruns and string of cancelled projects that have been announced for offshore wind developments. As a result, the current consensus is that it will take much longer for offshore wind to compete economically.

A growing number also believe that floating wind will not have a significant impact on the floating production sector. In 2022, only 13% held this view. Last year it grew to 20% and to 27%t this year.

Demand for floating hydrocarbon production systems remains strong and while there is certainly a huge potential for floating wind, costs have not declined as expected. Recent offshore wind developments have encountered delays and cost overruns, which has caused many to reassess their current and future investments.

Conclusion

The floating production sector grew further in 2023, continuing a rebound that began in 2021. Industry sentiment is extremely positive, with a record level of respondents optimistic about the future. These busy times are expected to continue for at least the next two to three years, despite expected cost inflation and growing supply chain concerns, particularly with fabrication facilities and shipyards.

About the Author

David Boggs

Managing Director, Energy Maritime Associates

David Boggs is the Managing Director of Energy Maritime Associates, which publishes market-leading reports on the floating production industry and advisory services for developments requiring FPSOs, FLNGs, FSRUs, semis, spars, TLPs, MOPUs, and FSOs. Boggs has over 20 years’ experience in the offshore oil and gas industry including as General Manager–Commercial for fleet of leased FSOs and FPSOs. He has a BA cum laude from Harvard University and an MBA with honors from the University of Texas at Austin.