Multilateral, intelligent technologies prove winner for Glitne

Dave Westgard

Adam Anderson

Baker Oil Tools

Statoil has combined advanced multilateral and intelligent well technologies to increase production, tap additional reserves, and control water production in its Glitne field.

The enabling technology includes a re-formable multilateral junction and incorporates a hydraulic intelligent completion system with a multiplexing device. The combination allows operation of a balanced-line flow control device with a single penetration through the wellhead.

Statoil’s Glitne oil field is a subsea development in approximately 330 ft of water in the Sleipner area of the Norwegian North Sea. The field is in a turbidite reservoir of Tertiary age, characterized by complex sand distribution with good vertical connectivity and somewhat lesser lateral connectivity.

Discovered in 1995, the field came onstream in 2001. With total reserves originally estimated at 40 MMbbl and peak production at 40,000 b/d, Glitne qualified as the second smallest of Statoil’s 20 Norwegian oil and gas fields. Producing from an FPSO helped make the field economically feasible. Original estimates called for the field to produce until 2003.

In early 2004, based on new information from its existing wells and reinterpretation of seismic data, Statoil upgraded total oil reserves for Glitne to 50 MMbbl and doubled the field’s producing life to 2007. Statoil also doubled its estimated total number of production wells for the field.

Multilateral design

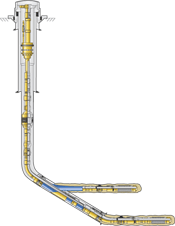

In April 2004, Statoil began constructing its Glitne A-6H, a multilateral designed to drill two laterals from a common wellbore in a new section of the reservoir. In this application, the position of the subsea wellhead would otherwise have limited the operator to a single, extended-reach lateral. Using a multilateral design enabled Statoil to drill and complete a second lateral to tap new reserves from a different section of the reservoir from the same wellbore.

The formation lithology (sandstone with layers of siltstone and claystone) called for sand control and for mechanically supported multilateral junctions with integral hydraulic integrity. The downhole environment in the Glitne field dictates using corrosion-resistant alloy materials for completion longevity. Additionally, Statoil wanted full re-entry and production isolation capability into both lateral sections and wanted the option of producing both zones independently or commingled. To address these issues, Statoil selected a well design based on Baker Oil Tools’ new multilateral system with Excluder sand control screens in each lateral.

The system consists of a main bore and two cased legs, of which one is pre-formed. The system deploys in casing and then re-forms in a casing window, providing a mechanically sound junction with integral hydraulic integrity. The ability to re-form the leg in the casing window increases the branch/parent diameter ratio, substantially increasing the effective flow area over conventional Level 5 multilateral completions.

Wellbore construction

For the Glitne A-6H, Statoil began well construction drilling a 12 1/4-in. hole to 6,528 ft MD and running 9 5/8-in. casing with 10 3/4-in. top surface casing to 8,445 ft MD. The company drilled the 8 1/2-in. main-bore section to 13,539 ft TD and completed it using an Mpas openhole packer, glass disk sub, and 5 1/2-in. Excluder premium sand control screens. The packer was activated by running a whipstock “dummy” string and shifting tool. Statoil created the 8 1/2-in. casing exit using a one-trip WindowMaster casing exit system. The upper 8 1/2-in. lateral section was then drilled to 13,560 ft TMD.

After retrieving the whipstock, the crew cleaned the well using a VACS tool and wellbore filter assembly, and then installed a seal bore diverter assembly, Excluder screens, openhole packer, FORM 5 junction, and liner hanger. The liner hanger featured internal Navigamma MWD tools for tool alignment. Statoil used a 5 3/4-in. Catexx hydraulic expansion system to expand the lateral leg to 4.56 in. ID. The swage diverter was retrieved and the glass disc sub was removed from the main bore.

In multilateral wells where the laterals contact different portions of the same reservoir, gas or water breakthrough in either of the laterals can negatively impact production. Therefore, in addition to multilateral capabilities, Statoil wanted the Glitne A-H6 to include intelligent well technology to remotely control flow from the lateral at the junction without rig intervention, in anticipation of eventual water breakthrough. Additionally, the company hoped to gain valuable reservoir and production data from the downhole sensors. Statoil selected an InForce intelligent well system with an HCM+ remotely controlled hydraulic valve for open/close flow control.

The HCM valve is a balanced-line flow control device that requires alternate pressuring on its open and closed hydraulic input lines to shift the sliding sleeve. The balanced piston concept ensures reliable operation, as it provides up to 17,000 lb of force to shift the valve open and closed. However, the design requires two hydraulic lines from the surface. This requirement can become problematic for intelligent well installation in subsea wells, where trees have few available penetration lines. The Glitne A-6H was one such well.

Multiplexing device

To address this issue without sacrificing the inherent reliability of a balanced hydraulic actuator, Statoil used a multiplexing device known as a Single Line Switch (SLS). A single line runs from the surface to the switch, while two lines run from the switch to the HCM+. By applying hydraulic pressure from the surface, the switch diverts flow to one hydraulic line and shifts the HCM+ open. Bleeding pressure off and re-pressurizing the control line at surface drives the valve closed. Vent fluid discharges to the annulus. Thus, a single zone requires only a single hydraulic line penetration, while a two-zone completion would require only two lines from surface rather than four. The SLS is designed and tested to be actuated once per month for up to 10 years. It can withstand 10,000 psi control line pressure, 7,500 psi annulus and tubing pressure, and temperature range of 40-325° F.

After Statoil completed the Glitne A-6H multilateral system, the crew installed the InForce system with SLS, production packers, gas lift valves, and safety valves. The company cleaned up and production tested the well by individually flowing from each lateral. The use of a single hydraulic line to surface ensures that running time for the intelligent well is similar to that of a conventional completion.

The final result was a dual lateral well with remotely controlled lateral production that would have been uneconomical to drill and complete using a conventional configuration of two single laterals. Based on the success of this well, additional multilateral installations are being considered for the Glitne field.