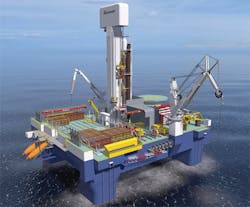

Heave compensated rig floor enables MPD, helps reduce NPT

Technology expected to be game changer for North Sea

Dieter Wijning,Huisman

The key challenge for floating rigs in the North Sea is reduction of NPT caused by downhole issues and waiting on weather (WOW), which can range from 15 to 35%. The technique of managed pressure drilling (MPD) was developed to reduce downhole issues and to drill the “undrillable.”

Huisman’s patented Heave Compensated Floor (HCF) solves this issue since the drill pipe is 100% of the time heave compensated. Said another way, the drill pipe is not heaving up and down, even when the vessel is heaving in heavy North Sea conditions. Basically, a stationary, jackup-type operation is created on a heaving floater.

Huisman’s Heave Compensated Floor (HCF) is expected to enable North Sea drilling contractors to employ the managed pressure drilling technique on floaters.

Often, when the downhole pressure of the mud in the well is lower than the pore pressure, an uncontrolled hydrocarbon influx is induced, i.e. a kick or potential blow out. When the downhole pressure of the mud in the well is higher than the fracture pressure, the formation is fractured and mud is lost (mud flows uncontrolled into the formation). In formations with a tight margin between the pore pressure and fracture pressure, the MPD technique can be applied.

MPD is a known drilling technique where the downhole pressure of the mud in the well is actively kept constant. This can be done in several ways, but most common is actively adjusting the surface back pressure on the mud return line on the rig. When the mud pumps are started the flow of mud through the well creates a higher downhole pressure: the backpressure on the rig is lowered to keep the downhole pressure constant. When the mud pumps are stopped, the downhole pressure drops. The backpressure on the rig is increased to keep the downhole pressure constant. The variation of the downhole pressure is kept within +/- 2.5 bar margin. MPD is regularly deployed on fixed drilling installations, jackups and sometimes on floaters (in benign weather conditions).

MPD cannot be deployed currently on floaters which experience significant heave. When the drill pipe is hung off in the drill floor, 3.5 m heave (which is a typical North Sea condition) can result in downhole pressure fluctuations up to 30 bar. Wells with tight pressure margins in waters deeper than approximately 130 m (maximum water depth for jackups) and waves higher than 3.5 m cannot be drilled. Areas with these conditions do exist and these cannot be economically exploited today.

The disruptive technology of the HCF (with the robotic drilling system) brings:

• Enabling MPD on floaters in heavy weather

• Enabling the running of (smart) completions on floaters in heavy weather

• Increasing safety during workover type operations

• Reducing weather related down time.

Employing the MPD technique on floaters is difficult as heave causes downhole pressure fluctuations. This applies to both surface back pressure and controlled mud loss-type MPD systems. Also, completion tubing control lines cannot be run in heavy seas as the heave motion of the tubing in the casing, when hung off, will cause damage to the control lines.

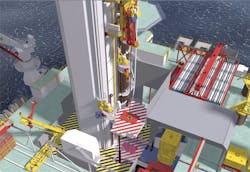

By introducing the HCF, a movable drill floor which can heave compensate the tubulars when hung off in the slips, creates a way of handling tubulars which is heave compensated anytime, enabling MPD system on floaters in heavy seas. Further the HCF eliminates the problem of damaged completion tubing control lines and the HCF can act as a HC tension frame for work over operations.

With the Heave Compensated Floor, drill pipe is heave compensated 100% of the time, which in effect creates a stationary, jackup-type on a heaving floater.

The HCF can work in two modes:

1. Conventional fixed to vessel mode; the floor is lowered flush with the main deck. Riser tensioners support the riser via a telescopic joint.

2. Above mentioned HC mode; hydraulic cylinders compensate the floor. The telescopic joint is fully stroked out.

When the floor is flush with the deck various objects can be easily skidded onto the floor to the well center. The floor also can be raised for launching large objects, such as the BOP or subsea mud lift pump, eliminating a substructure.

By integrating the accommodation in the three (i.s.o. two)-layer deckbox, the accommodation superstructure can be eliminated and a flush deck space of 1.7 times the competition is created. The flush deck and skidding systems avoid swinging crane loads and avoid workers to work on the deck.

Market readiness

The HCF is based on existing technologies. It is a smart rearrangement of existing equipment. The Huisman Innovation Tower (HIT) in the Huisman yard, a full-scale drilling test tower with automated robotic pipe handling, will serve as a test bench for the HCF and additional machinery. Underneath the HIT a 400-m deep test well together with an MPD mud system is present, which can be perfectly used for various downhole tests.

The flush deck arrangement and accommodation located inside the deckbox of the semi has been done before on various other semi-subs and is therefore considered market ready. Huisman is currently working closely together with reputable naval design houses to incorporate the design features mentioned into their proven drilling semi-sub designs.

Market potential

MPD is required to drill certain wells because of potential well control issues, such as: HPHT wells, wells in marginal/depleted fields and ‘undrillable’ wells. Also one can argue that every single well should be drilled with MPD, not only because of well control issues, but for efficiency improvements:

1. Reduce the number of potential well control events.

2. Increase the rate of penetration.

3. Increase the oil/gas recovery rate by lowering the skin factor.

A large number of these wells are located in water depths in excess of 130 m, which is the maximum for jack ups, and therefore need to be drilled from floaters. The HCF basically creates a stationary, jackup-type environment on a heaving floating rig. When looking at the difference of downtime figures (NPT and WOW) between floaters and jackups, one can easily see that the gains are massive.

Business benefit

Creating a way of handling tubulars which is 100% heave compensated solves various technology gaps. This enables MPD system on floaters in heavy seas as heave is no longer causing downhole pressure fluctuation possibly causing kicks or lost circulation related downtime. This applies to both surface back pressure and CML type MPD systems.

Currently completion tubing with control lines cannot be run in heavy seas as there is a high potential of control lines damage when the tubing is heaving when hung off in the slips (e.g. when connecting to the tubing hanger). The HCF eliminates this problem as the tubing will be heave compensated when hung off. Also, the HCF can act as a HC tension frame for work over operations, with ample safe access and proper rig up/rig down procedures.

The HCF reduces the NPT caused by WOW, saving 15-35% time/cost per well.

The massive flush deck and skid systems provide ample space and safe handling of any combination of payload, improving overall rig efficiency.

Summary

Key advantages of the HCF technology include:

• Significant improvements in terms of workability and efficiency. Wells can be drilled in 30% fewer days, resulting in 30% less emissions.

• Improvement of safety and less cost for offshore personnel. Less people on board (less cabins, less need for helicopter-transportation, catering, etc.). Simplified logistics.

• Improvements are not only for MPD drilling operations but also for completion operations, and coring operations, etc. (not discussed in detail here).