Hurricane preparedness

David Petruska, BP

Steve Leverette, SBM-Atlantia

Bob Wolfram, ExxonMobil

Jim Stear, Chevron

Skip Ward, Offshore Technology Research Center

David Wisch, Chevron

A number of API’s recommended practices are being revised based on what was learned in the 2004-2005 hurricane seasons as well as recent design and operational experience.

An article, “Response to hurricanes - significant, diverse, widespread,” published inOffshore in June 2007 summarized API’s initial assessments of the impacts of the 2004-2005 hurricanes and the collaborative efforts with member companies to incorporate lessons learned into improved design guidance. API interim bulletins were issued and rolled out to the industry via API forums, an Offshore magazine webcast, and conferences. Several in-depth studies were initiated to further examine and to better understand the more critical observations.

Work also was initiated to incorporate this new knowledge and experience into revised recommended practices that will supersede the interim bulletins. This article summarizes the progress and status of revisions to several recommended practices.

MODU moorings

Mooring failures during hurricanes Ivan, Katrina, and Rita resulted in the total or partial loss of station keeping for 24 MODUs. Some drifted many miles through the offshore infrastructure of floating and fixed platforms, subsea wells, and pipelines, and resulted in the potential for damage from collisions or anchors dragging over pipelines. TheAPI RP 2SK Task Group (Station Keeping) was reactivated and rig owners, contractors, and regulators joined operators to address these mooring failures. The MODU Mooring Strength JIP also was launched to study the failures and successes of mooring systems for MODUs exposed to these storms, and to look at ways to reduce risks and improve future performance. The task group and the JIP collaborated to revise guidelines incorporating many of the JIP’s results.

API RP 2SK 3rd Edition, published in October 2005 as a result of API’s policy to update or reaffirm each RP every five years, incorporated a number of important and useful improvements and updates. Failures observed during Ivan were being studied as the third edition went to press. API decided to issue the third edition to incorporate learnings from Ivan — and then Katrina and Rita — into interim updates and commentaries as soon as possible. The task group developed API 95F Interim Guidance for Gulf of Mexico MODU Mooring Practice – 2006 Hurricane Season 1st Edition (May 2006) and 2nd Edition (April 2007) and a commentary to API RP 2SK 3rd Edition was published in May 2008. This has allowed the task group to get the latest information out to the industry as learnings from Ivan, Katrina, and Rita evolved.

The API RP 2SK Commentary incorporates these learnings. The commentary provides a framework to determine the acceptability of a MODU to drill at a given location during hurricane season. It is based on risk assessment and the consequences of the MODU’s mooring failure. The commentary recommends three levels of risk assessment:

- Initial Screening

- Basic Risks

- Supplemental Risks.

This process begins with theInitial Screening Assessment.

Consequence classes are characterized by type (structures, pipelines) and production rates of nearby infrastructure and its distance from the proposed MODU drill site. Most MODU locations will fall into one of three consequence categories as shown above:

Risk-based analyses were used to estimate appropriate return periods for the metocean condition that should be used to design mooring systems for each consequence category. Risk was taken to be theprobability of an adverse event multiplied by the consequences of that event. Financial consequence were examined quantitatively, whereas the other consequences were considered in a more qualitative or subjective manner. This initial assessment assumes the risks are not mitigated.

The return period for metocean conditions for the most common consequence categories during a hurricane are shown in the adjacent table.

For the 10-year return periods and with the new Central Zone metocean criteria, design loads on mooring systems have increased by about 60%. In the other zones, the increase in loading is not nearly as severe. From the prior 10-year return period to the new Central Zone 20-year return period, design loads on mooring systems have more than doubled. From the former 10-year return period to the new Central Zone 50-year return period, design loads on mooring systems have approximately tripled.

TheBasic Risk Assessment can consider the following consequences:

- Personnel health and safety

- Environmental damage

- Financial loss

- Corporate reputation and image

- Industrial reputation and image

- National interest.

The basic risk assessment must be completed following the initial assessment and should quantitatively address:

- Potential mooring failure modes

- Mechanical integrity of the MODU’s mooring system

- Probability of mooring failure

- Likelihood and consequences of damage to nearby infrastructure due to a mooring failure

- Impact of operational options on failure or consequences

- Mitigation options to reduce the probability of failure or the resulting consequences.

The probability of failure for the mooring system should be estimated from the load expected to fail the mooring system, the metocean conditions that could cause such a load, and the return period associated with that metocean condition. Hurricane metocean condition inAPI Bulletin 2INT MET for that site should be used, along with the present mooring system analysis methodology, which adequately predicted the successes and failures observed in recent hurricanes. The analysis should estimate the actual capacity of the mooring line strength and anchor capacities, and the impact of various mitigation measures. The mooring line strength should reflect the most recent mooring line and component inspection in accordance with the recently revised API RP 2I issued in 2007.

Results will describe the mitigated risks of the proposed MODU at the drill site. The risks may be acceptable, or may suggest that another more remote drill site should be considered for that MODU during hurricane season and the original location should be drilled after hurricane season.

If the MODU is not on site during the peak of hurricane season, seasonal criteria can be used and are available now in the recently issuedAddendum 1 to API Bulletin 2INT MET.

TheSupplemental Risk Assessment can be used to further assess specific critical risks identified in the Basic Assessment and to more thoroughly evaluate mitigation measures for non-financial risks. This assessment is required for atypical MODU operations, i.e. offset drilling from MODU, tender-assisted drilling adjacent to a permanent facility, and MODU operations within the mooring radius of a permanent facility.

API RP 2I 3rd Edition was published in April 2008. Major changes address the inspection of fiber moorings and guidance on assessing damage and need to retirement, mooring component traceability, inspection, retirement documentation, MODU mooring inspection for areas prone to hurricanes, and inspection of permanent moorings

Most of the changes focus on enhancing the reliability and performance of MODU moorings during the hurricane season. Some of the major changes are summarized here.

Inspection of fiber mooring. Polyester rope moorings have become a commonly used mooring line for preset MODU mooring systems and also have been used in several permanent moorings. Guidance on inspecting and handling damage to this material was needed since demand had increases subsequent to the release of the second edition.

Ropes that have been damaged during installation or while in service need to be assessed to determine if they can remain in use or if they need to be retired. Damage can be concentrated, distributed, in the splice region, or to the jacket. The ropes also may be adversely affected by marine growth, soil ingress, and twisting.

For fiber ropes,API RP 2I 3rd Edition mostly addresses concentrated damage. Concentrated damage may be assessed using the allowable strength reduction or allowable fiber area reduction method. The rope may remain in service provided the remaining strength is greater than 90% of the original specified minimum breaking strength (MBS) per API RP 2SM (same criterion that has been used for steel components).

Two JIPs were undertaken to investigate explicitly the damage tolerance of polyester ropes to aid in developing discard and retirement criteria. Both projects looked at different degrees of simulated rope damage to develop the relationship between the damaged strength versus extent of damage. Unfortunately, results were of limited value for developing generic discard criteria due to the limited number of undamaged and damage tests conducted, significant scatter in the damaged rope test data, and the use of ropes with different constructions. This showed that rope design had an impact on damage tolerance. However, the test results indicated that the allowable damage to satisfy the 90% remaining MBS criterion is small.

The RP does not recommend the use of test inserts for inspecting or assessing the long-term strength of ropes in permanent mooring systems. Industry experience from conducting such tests indicates the information gained has been of limited benefit. However, regulatory requirement presently calls for test inserts as part of the inspection plan. For MODU moorings, inserts are not recommended since the entire rope is routinely brought to the surface.

The reduction of strength due to ingress of soil particles into the load carrying core resulting from rope contact with the seafloor can be justification for discard of the effected portion of the rope. However, today’s ropes generally use particle filters which have been shown to be effective at preventing the ingress of soil particles to the load bearing core.

Mooring component documentation. Guidance is provided on documentation requirements to maintain a complete, auditable record of the history of all mooring components from cradle to grave. This helps ensure that all components meet the minimum requirements for use during hurricane season.

MODU mooring inspection for areas prone to hurricanes. Guidance is provided for a rigorous mooring inspection that should be completed prior to operations in hurricane season and also to ensure mooring integrity and to minimize the probability of mooring component failure. Guidance also is provided for inspecting components following a failure due to overload, and conditions for reuse in subsequent operations.

Deepwater production systems

The first API recommended practice to address deepwater production structures wasRP 2T for TLPs. It was first issued in 1987 and revised in 1997. Until a few years ago, RP 2T was the only API RP that addressed deepwater floating production systems. Although focused on TLPs, RP 2T along with other classification society documents and European codes, served as a technical basis for other types of deepwater floating structures. API RP 2FPS, which addresses other floating systems such as spars, semisubmersible production systems, and FPSOs, was issued first in 2001.

The impetus to updateRP 2T and RP 2FPS was driven by several factors. Operational experience and technology for both TLPs and FPSs have grown significantly, and new concepts and configurations for these structures have evolved. Engineering design tools and practices have improved greatly. And the understanding of the Gulf of Mexico environment has changed significantly following the 2004 - 2005 hurricane seasons.

API RP 2T 3rd Edition is scheduled to publish this year. It is a substantial update based on 20 years of experience with 24 installed TLPs. In that time, substantial progress has been made in platform types, design methods, and procedures.

Some of the evolution of TLPs over the past 25 years is evident in the major configuration variations. The third edition ofRP 2T is intended to cover all of these TLP types (except for concrete TLPs), and to provide a basis for future permutations.

One of the most significant changes is the shift from being a consensus “primer” on TLP design, into a more code-like document with “code equations” for checking the design.

A probabilistic design check is required to ensure that the environmental load cases used in the design cover a sufficient range of wind, wave, and current combinations. Deepwater structures respond dynamically to the environment, which results in a more complex process required to evaluate extreme responses to combined environmental factors. More specific requirements for a required probabilistic design check are provided along with guidance in using response-based criteria, which help ensure satisfactory results from this final design check.

A 1,000-year survival check is specified for deck clearance and minimum tendon tension, and to assess the overall robustness of the TLP system in performance beyond the design level checks. The latter criterion was in response to the lessons learned from the 2004-2005 hurricane season. These robustness checks are not intended to increase general safety factors, but to let the designer, operator, and owner identify and understand the potential first failure points for the system to encourage a more balanced design with potentially higher overall system reliability.

Guidance is provided on TLP ringing responses and vortex induced motions and vibrations of the hull and tendons, and extensive guidance is provided on marine systems. This topic has not been covered in an API RP, and represents a considerable contribution, which may be used for other floating systems.

A task group is currently preparing a second edition ofAPI RP 2FPS according to the SC2 document strategy of aligning and merging it with a corresponding ISO offshore structures standard. ISO 19904-1, for floating structures, was developed in recent years using much of RP 2FPS as a base document, with current practices and learnings from industry experience with FPS units around the world.

The merging and aligning will be done via the use of an API wrapper toISO 19904-1. The wrapper will include provisions currently found in RP 2FPS that are not included in ISO 19904-1, and a few technical updates based on recent industry experience. The second edition of RP 2FPS will consist of ISO 19904-1 as the core document, which will be unchanged, and the wrapper as an overlay.

Technical updates toRP 2FPS will focus primarily on incorporating lessons learned from recent GoM FPS projects and on addressing issues raised by the reassessment of the GoM hurricane environment. Guidance on hurricane preparedness and survival of floating platforms that was included in API Bulletin 2INT-DG will be incorporated into RP 2FPS, including:

- Clarification of the air gap design requirements and provision for a check of the air gap in a rare event, i.e. a 1,000-year wave crest, to ensure robustness

- A weak point analysis of the mooring system to identify the probable failure mode and mitigation measures if appropriate

- A robustness check of structural integrity and stability in a hurricane with return period longer than 100 years.

A second area of focus will be on requirements for the use of disconnectable FPSOs. The initial application of the FPSO concept on the OCS is designed to be disconnectable to mitigate damage from hurricanes. The guidance currently inISO 19904-1 will be reviewed in light of industry experience in other parts of the world and the typical approach to hurricane abandonment of platforms in the GoM, to ensure that design requirements are consistent with realistic operational scenarios.

null

Metocean conditions

API Bulletin 2INT MET was published in 2007 and contains updated hurricane wind, wave, and current conditions that incorporate learnings from hurricanes Ivan, Katrina, and Rita. Addendum 1, issued in 2008, extends that information to include seasonal conditions on hurricanes. Hurricane season officially runs from June 1-Nov. 30, with the most severe activity generally occurring during August, September, and October. Seasonal conditions are provided for the pre-peak (June 1-Aug. 1) and post-peak (Oct. 21-Nov. 30) seasons, and can be useful in planning operations scheduled for those periods. During the peak season, conditions based on the total population of hurricanes throughout the year should be used (same conditions as used for the design of permanent structures). The addendum also includes deepwater hurricane conditions associated with the Saffir-Simpson Scale for hurricanes.

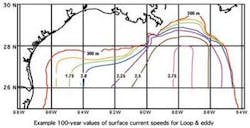

A stand-alone API RP on metocean conditions, tentatively designatedRP 2MET, is being developed. This document represents a new chapter in API offshore standards in that metocean conditions are being broken out from their traditional location in RP 2A for shallow water fixed platforms. In the present era of offshore development, additional metocean guidance needs to be provided for deepwater platforms and floating MODUs, which are covered by different API RPs, e.g. 2T (TLPs), 2FPS (Floating Production Systems), 2RD (Risers), and 2SK (Moorings). In addition to hurricane wind, wave, and current conditions, these deepwater facilities and risers must withstand additional types of currents that occur in deepwater. API RP 2MET will contain extensive guidelines on hurricane conditions in the GoM (including the updated hurricane conditions published in 2007 in API Bulletin 2INT MET), as well as guidelines on other phenomena such as sudden hurricanes, winter storms, seasonal criteria for short-term operations, Loop and eddy currents and other deepwater currents, and joint hurricane-eddy current conditions.

API 2MET will be aligned with the ISO metocean standard 19901-1, and will follow the “align and merge” strategy to reconcile API and ISO standards. The new RP 2MET document essentially will be a copy of the existing ISO 19901-1, Petroleum and Natural Gas Industries – Specific Requirements for Offshore Structures – Part 1: Metocean Design and Operating Considerations, with key changes and updates to various sections to cover the GoM. API Bulletin 2INT MET was published as a stand-alone metocean document as a step towards a stand-alone RP on metocean conditions. API RP 2MET is expected to be issued in 2009.

Authors’ note

More information is available in 2008 OTC papers: 19602 (API RP 2MET), 19603 (API RP 2T and 2 FPS), 19606 (API Offshore Standards in general), and 199607 (API RP 2SK).

Mooring upgrades

Soon after hurricanes Ivan, Katrina, and Rita there was a strong drive by the industry and regulators to improve the MODU fleet’s mooring capabilities. Even before the new requirements were established, while yards and equipment suppliers were swamped with repair and recovery activities in addition to demands for drilling and production systems, the offshore drilling industry started upgrading MODUs as rapidly as possible. Mooring upgrades for most MODUs involved adding an additional mooring line per column, such that eight- and nine-line systems became 12-line systems. The extra lines increased the storm capacity of many MODUs by 30-50%. In addition, many operators have augmented mooring systems with polyester mooring lines and higher capacity anchors. This has created a strain on the availability of polyester rope and high capacity anchors, and increased demand for high capacity anchor handling boats.

Webcast panel discusses hurricane preparedness

On July 23, a panel of industry experts discussed the latest API initiatives in developing recommended practices for MODU moorings and floating production systems. Lessons learned from recent hurricanes were also included in the discussion. Access the free online webcast event archived atwww.offshore-mag.com/webcasts.