Two Cook Inlet operators find success with innovative strategies

By Bill Penrose,

Bobby Smith,

Mike Langeler

XTO Energy Inc.

Paul White,

Rob Stinson

Forest Oil & Gas Inc.

Lee Smith

Alaska Energy Resources Inc.

Carey Perry

Security DBS-HES

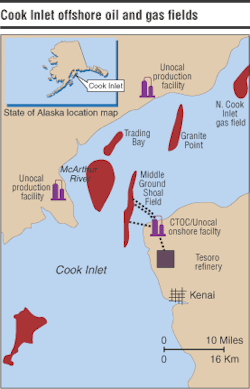

Alaska's Cook Inlet operators are imple-menting innovative directional strategies to extend commercial applications in the difficult target formations of the Middle Ground Shoal Field, infusing new life and interest in a field that has produced since the mid-1960s.

In an application that traditionally requires multiple roller cone bits and regularly destroys polycrystalline diamond compact (PDC) bits, operators are devising directional drilling plans that maximize exposure to the target by using advanced cutter technology to withstand longer hours in the interbedded formations.

Discovered in 1963, the field is offshore Kenai and has never been a common application for PDC technology. In fact, Cook Inlet formations are notorious for wiping out PDC bits - sometimes in as little as 150 ft. "Good" runs are 500 to 1,000 ft, while roller cone bits typically achieve runs between 200 and 600 ft. However, a new cutter design that backs up premium PDC cutters with diamond-impregnated cylinders provides a dual cutting structure that has been shown to drill faster and last longer than both roller cone and conventional PDC bits.

Having just completed two runs with the Elite Series bits, operators XTO Energy Inc. and Forest Oil & Gas are running the advanced cutter PDC designs on two offshore rigs in the area. Another major operator recently logged a 5,000-ft run in 55 hours on land with one of the Elite bits from Security DBS.

XTO used an 8 1/2-in. FM2643R with the advanced cutters to drill for more than 100 hours and 2,500 ft. This FM matrix body bit run followed a 2,500-plus-ft run with a similar, steel-body FS design with Elite cutters.

Having total depth (TD) of the section at a measured depth greater than 20,000-ft, a 6 3/4-in. similar type bit has drilled more than 900 ft for Forest Oil, run both in sliding and rotating modes. The performance is the first single bit run to TD the section, leading Forest Oil to now consider drilling the entire 6 3/4-in. section exclusively with these bits, where previously, at least five insert bits were planned.

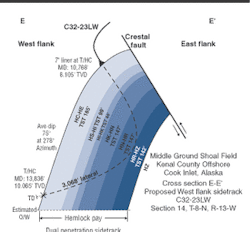

This new cutter technology has allowed XTO Energy to use an innovative dual penetration directional strategy to maximize exposure to the target formations. The U-shaped dual penetration trajectory has allowed economic commercial development of applications previously not even considered PDC-drillable.

In early April, Forest Oil completed the deepest well ever drilled in Cook Inlet, reaching a measured depth of 20,203 ft in the Redoubt No. 4 well, designed to determine the down dip limit of the field. The well extended the lowest known oil by 50 ft without encountering the oil-water contact.

Difficult target

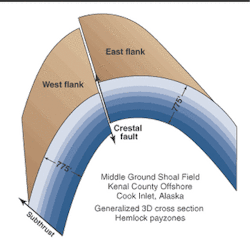

The Middle Ground Shoal Field in Alaska's Cook Inlet is a north-south trending asymmetric anticline with east and west flanks isolated from each other, from a pressure standpoint, by three high angle thrust faults. In addition, the east flank dips up to 55°, while the west flank is nearly vertical-to-overturned in places. The field produces from multiple zones within the Hemlock member of the Tyonek formation, between 7,300 ft and 10,000 ft total vertical depth (TVD).

The Hemlock pay is comprised of six sandstone/conglomerate sub-intervals, stratigraphically separated by impermeable siltstones, fine-grained sandstones interbedded with pebble conglomerates. The upper sands tend to be sandstone-dominated, while the lower sections are primarily conglomerates. Porosities average 9-10%, with permeabilities ranging from 0-50 md.

The depleted west flank of the field was the primary target for development, as it was underdeveloped and isolated from the east flank pressure maintenance program. Using wellbore data from 31 previous west flank penetrations, the operator mapped six Hemlock sub-interval net pay isopachs and identified several "holes" where additional deviated wellbores could be placed, including a few with more than one location in multiple zones.

The tempting targets, along with high offshore drilling costs and few sidetrack alternatives, led the operator to consider drilling two locations with one wellbore, as Shell had done in the mid-1990s. Then, Shell successfully added dual penetration sidetracks to two existing west flank producers, both of which were nearly horizontal. The plan was to drill across the top of the anticline, set casing at the top of the west flank, and drill dual penetration wellbores with strong vertical components.

Prior to this, PDC bits had little success drilling the reservoir and overlying Tyonek formation due to the widely varying lithologies encountered over short intervals. The PDCs were not sufficiently robust to drill through the sands, silts, coals, and conglomerates typically encountered in any bit run over 100 ft. The dual penetration drilling program at Middle Ground Shoal offered an opportunity for development of a PDC bit that could withstand the harsh lithology to achieve much longer bit runs and reduce trip time.

Advanced cutter PDC designs

The Elite PDC cutter technology is an enhancement of the proven Deep Ring Claw (DRC) cutter, a premium thick diamond PDC cutter that offers impact resistance approaching that of much thinner diamond layer products. To further increase bit life and drill through unknown sections, these bits combine the premium DRC cutters with impregnated disks as back-up, creating a dual-cutting action bit. While the PDC cutters shear the rock, the impregnated disks add a micro-shearing failure mechanism for maximum drilling efficiency in medium-hard formations.

Backing up the premium PDC cutters with diamond-impregnated cylinders provides a dual cutting structure that drills faster and lasts longer than both roller cone and conventional PDC bits. The diamond-impregnated cylinders trail the cutters in a seamless direct extension. Thus, when abrasive rock is encountered, the cutters wear down slightly, and the diamond cylinders effect a micro-shearing action. Even in the instance of impact damage, the secondary active cutting structure takes over for the leading cutter, essentially extending the application to harder formations.

Key to this technology is a proprietary process for producing diamond segments and disks at a lower temperature, resulting in self-sharpening synthetic diamonds with the strength and durability required for drilling difficult formations. The diamond segments and disks are incorporated into the bit designs in a double phase impregnation process that produces a self-sharpening cutting edge, as well as protection from erosion and abrasive wear.

The performance gained from the new cutters has been the step change necessary to facilitate consistent good runs in the fluvial formations of the Cook Inlet Basin, where the pay zone can be encountered as deep as 15,000 ft TVD. In addition, the dual penetration strategy employed by the operator in this case required not only extended bit life but also directional capabilities as doglegs exceed 3°/100 ft.

Consistent drilling performance

Drill bit performance is improved by longer bit runs with fewer trips to replace worn bits, by increased rate of penetration, or by both. Use of the new bit designs with natural diamond-impregnated back-ups provided a clear advantage to Cook Inlet operators in terms of improved performance. The new dual cutting structure bit ultimately developed has replaced multiple roller cone runs at lower penetration rates, with faster drilling bits that don't run the risk of leaving a cone in the hole.

Using this cutter technology, Forest Oil has realized faster penetration rates while drilling to TD with the 6 3/4-in. bit. This bit was run with a 5-in. Sperry Drill (6/7) mud motor with 1.22° bend, and integral stabilizers at 28 and 75 ft from the bit.

This bottomhole assembly had a 3-4°/100 ft left-hand walk tendency. Sliding was difficult and nullified the walk, but could not bring the hole back to the right. The slides were made as far as the formation would allow, usually 10 ft to 15 ft, after which the hole had to be reamed out. In addition, the stabilizers appeared to be hanging up.

At the depth of 19,769 ft, a short trip to the shoe was made, pulling up to 18,960 ft and back reaming to 18,933 ft, then washing to the shoe at 18,516 ft. The short trip allowed hole conditions to be considered for the possibility of coring, which was disregarded.

Drilling ahead still required some 40% sliding to counter the walk/drop tendency. Also, rate of penetration (ROP) through the Hemlock is slow, with an average of 9 ft/hr. However, at the bottom of the Hemlock, ROP increased to 18 ft/hr, drilling to TD at 20,203 ft. The bit drilled a total of 951 ft in 95 hours, for an average ROP of 10 ft/hr, in what is one of the best bit runs in the field to date.

Summary

Additional field data confirms that advances in cutter technology have enhanced drilling capabilities beyond that expected from simply replacing roller cone bits in these conglomerate, abrasive formations. The data trend consistently illustrates best-in-class performance, facilitating more complex and demanding drilling strategies that ultimately will enable operators to more fully realize the potential of the Cook Inlet fields.

Both XTO Energy and Forest Oil have developed truly innovative development strategies for the Cook Inlet that have allowed them to maximize their return on investment in this unique region.

Acknowledgments

The authors would like to thank XTO Energy Inc., Forest Oil, Security DBS-HES, Fairweather E&P, and Alaskan Energy Resources. Additionally, they thank Larry Driskill and Larry McAllister of XTO, BHI's Eric Brown and Jason Long Sr., as well as Inlet drilling tool pushers Brad Rasch and Jerry Sandidge, Inlet Drilling contractor/crew as well as the full range of services contractors. Additional thanks go to Forest Oil Drilling Foreman Mike Murray and Mike Mello and Toolpushers Mike Willams and Paul Barr. The authors thank Robert Wall and Joe Grubb, SperrySun Senior Directional drillers, Craig Asuchak, SperrySun Senior MWD operator, and the full Nabors Alaska drilling crew and service providers on the Osprey Platform. We also acknowledge John Kelety, Rusty Milam, Calvin Elmer, and Rozena Turner, and the staff of the Houston Waverly SDBS manufacturing plant.

About the Authors

Bill Penrose, consulting engineer, is Senior Drilling Engineer, Bobby Smith is Drilling Manager, and Mike Langeler is Senior Geologist, all for XTO Energy. Paul White is Drilling Manager, and Rob Stinson is Drilling Engineer, both for Forest Oil & Gas Inc. Lee Smith is President of Alaska Energy Resources Inc. Carey Perry is a technical professional with Security DBS-HES.