Larger rotary steerable systems designed for offshore applications

John Clegg, Weatherford

Following a focused and compressed development of less than two years, Weatherford launched its Magnus rotary steerable system (RSS) in April 2018.

The system addressed two key requirements for RSS tools that had emerged in the market in recent years. It was designed to be simple and cost effective to use, with much improved asset utilization compared with its predecessors, to reflect the economics of the current market. In addition, it was designed to reflect the way wells are currently drilled, with longer horizontals, faster drilling, more power to transmit, and more demands on wellbore quality. In short, the new system represented a fundamentally different approach from those used in the past. The following will discuss the new, larger diameter variants of the Magnus RSS which have been specifically designed for the offshore market.

At the time of its launch, the system was exclusively available as a 6¾-in. diameter tool, known as Magnus 675. This was to enable rapid testing of the sub-systems and components of the tool, using a “fail fast” philosophy in order to maximize learning and make the tool as robust as possible, as quickly as possible, before a commercial launch. In order to achieve this, a year-long testing program at a private facility in Oklahoma was devised. The new RSS was taken there about once per month, to drill for a week at a time. The development team was driven to resolve problems encountered during each drilling test within the approximately three-week period before the next test. Not all problems could be resolved within three weeks, obviously, but many were. The rest were resolved over two or three test cycles and the rapid cadence of these tests provided the springboard needed to quickly work all the major bugs out of the system. These tests culminated in the drilling of a vertical, curve and lateral well in Oklahoma in February 2018. This led directly to the commercial launch two months later.

The system has seen successful application in eight countries in North America, Continental Europe and the Middle East, in both onshore and offshore fields. At the time of writing (January 2020), it has drilled more than 550,000 cumulative ft (167,640 m). The longest single run in terms of footage is 12,482 ft (3,805 m), and the longest run in terms of hours is 346 circulating hours in 21 days downhole. The first of these was achieved in the northeast USA drilling the Marcellus shale, and the second was achieved in the Permian basin.

Buoyed by this initial success, larger tool sizes, 8¼-in., 9½-in. and 11-in., were developed.

Designed for offshore applications, these tools use the basis of design successfully proven with the 6¾-in. tool. They share the same fully rotating push-the-bit design. Even in these larger sizes, the absence of a rotating sleeve makes the tool as slick as possible, in order to minimize stuck pipe risk, and as strong as possible. Using push-the-bit technology allows the tools to be simple and cost effective. Regardless of size, the tool was designed to be capable of being repaired at any location with a breakout machine and an overhead crane, allowing repair and maintenance as close as possible to the location where the tool is used and thereby maximizing utilization, a key driver for RSS economics.

Magnus has three independently controllable and addressable actuators to push the bit sideways. This provides redundancy which means that the tool can likely continue to drill even in the unlikely event that one actuator fails, but also allows the tool to be “switched off” and only push the bit sideways when needed. This in turn allows the drilling of smoother wellbores and less tortuous wells and enables automated control of direction in so-called “autopilot” mode. It also allows proportional steering control, which means that the tool can drill a smooth curve at any dogleg between perfectly straight and its maximum rate. This is a unique capability for a fully-rotating RSS tool. An added benefit of being able to effectively switch the tool off is the ability to drill out the casing equipment, or to ream, without lateral bias of the drill bit interfering with the process. The larger tools use a duplicate of the control system developed and tested for the 6¾-in. tool, but with larger actuators to match the hole sizes for which they were intended and to provide the higher loads needed to lift and to bend the larger bottomhole assemblies used. The 8¼-in. tool builds on the established 6¾-in. to provide the ability to drill 10⅝-in. hole and facilitate offshore under-reaming while drilling to set intermediate liners. The 9½-in. and 11-in. tools are effectively identical to each other, apart from hole-size specific actuator designs and a larger box connection to match drill bit pins in the largest hole sizes.

Once the larger tools were designed and built and following lab testing in the R&D facility in Houston, a 9½-in. tool was taken to the Oklahoma test facility. A drilling test using the 9½-in. tool started in late August 2018.

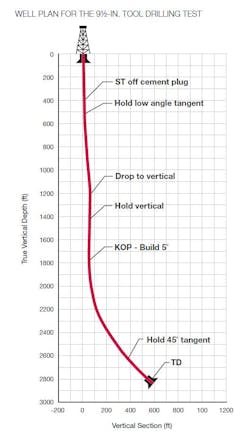

The test required the tool drill to a well plan as shown in the first figure. It was able to drill the plan in a single run, achieving the following objectives:

• Maintained a low angle tangent section using autopilot mode

• Drilled the vertical section using vertical hold mode with inclination below 0.5°

• Kicked off from vertical in open hole

• Achieved 6°/100 ft dogleg in the curve section

• Maintained 45° inclination using autopilot mode.

The test demonstrated all aspects of functionality without failure and thereby qualified the 9½-in. and 11-in. tools for commercial operations. The low-angle hold capability was tested here specifically to demonstrate this ability to operators in the USA. Following this qualification test, the Magnus 950 (as the 9½-in. tool is known) was launched drilling 12¼-in. diameter wells for these operators in the SCOOP (South Central Oklahoma Oil Province) and STACK (Sooner Trend, Anadarko, Canadian and Kingfisher) basins. Here it was consistently able to drill wells requiring kick off from vertical and holding a low-angle tangent for thousands of feet in difficult applications, using its autopilot mode to hold inclination and saving significant time when compared with motor-based applications. From here it went to Mexico, both onshore and offshore runs, where the same success was repeated and similarly smooth tangent sections, with minimal dogleg and minimal deviation from plan.

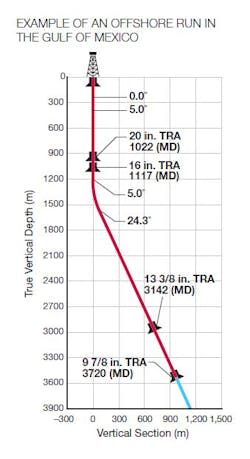

The second figure shows a typical example of an offshore run in the Gulf of Mexico. Here, autopilot mode was used for the entire run of 1,939 ft (591 m) in order to hold a 24.3° tangent to section target depth (TD). The maximum distance from plan throughout the run was 5.2 ft (1.59 m). There was minimal deviation from tangent angle and minimal dogleg, both which result from the use of the autopilot function. The smooth wellbore that autopilot can drill results in turn from the Magnus control system design and its three independently controllable and addressable steering pads.

At the time of writing, the Magnus 950 has been used on 29 runs, drilling more than 80,000 cumulative ft (24,384 m). A notable case history was recently achieved on an offshore well in the Arabian Gulf. This was an application drilling primarily argillaceous limestones and where there was a strong history of stuck pipe events. On the same well, two RSS tools had become stuck, requiring days to free them at significant cost to all parties involved. The slick design of the Magnus 950 was intended to prevent just such an event, and the tool was used to drill 1,774 ft (541 m) in a single run to TD, with no sticking or other dysfunctional drilling events. In this run, the well was built according to plan from 56.1° to 78.2° inclination, achieving a build rate up to 2.51°/100 ft as required. This dogleg was achieved with a 50% bias from the Magnus tool, indicating a dogleg yield consistent with the tool’s specification and showing that a smooth wellbore can be achieved when drilling at less than 100% bias. It is also noteworthy that the trip out of hole was slick, with no back reaming required.

The first deployment of the 11-in. tool was a 17½-in. surface hole application, drilling a 17½-in. hole while maintaining vertical over 1,903 ft (580 m).

Magnus 1100, as it is known, has been deployed twice in the Gulf of Mexico. In the first of these offshore runs, the tool was used to drill a 17½-in. section to 5,348 ft (1,630 m) TD, initially building with over 3.5°/100 ft to achieve the directional objectives of the well and then holding a 54.4° tangent section with distance to plan again held well within client limits.

Building on these successes, both Magnus 950 and Magnus 1100 are set for further deployment in primarily offshore applications around the world. Except for some large diameter drilling onshore in the Middle East, Magnus 1100 is expected to be deployed exclusively offshore with more work planned for the Gulf of Mexico. Also, the tools are expected to deploy in the North Sea in 2Q 2020.

As the case histories above have illustrated, these tools are well suited to solving the challenges associated with offshore applications and bring new options for drilling challenging offshore directional wells. •