Digital well delivery requires contextualization

Dr. Per Arild Andresen, Cognite

Digitalization of well delivery—from well construction to completion—requires a shift in thinking about data ownership and data control. Accessing high-quality data is the first and biggest bottleneck, but digital transformation will also require an advanced solution founded on principles of data liberation, data contextualization, and data sharing.

Today, each step of drilling activity planning is performed in separate spreadsheets/documents and legacy applications. All require point-to-point data integrations, frequent data import/export, and manual data entry. Reusing data in this scenario is extremely cumbersome, limiting the ability to learn from previous activities or to scale the ones that work.

Scalability is the ultimate victory, of course. Nearer term digital goals would be to use data to make better plans and to communicate the drilling activity plan to all stakeholders and partners involved in the value chain. But by approaching digitalization the right way, scalability remains an important motivator, influencing priorities and tactics toward standardization along the way.

Cognite has spent the last few years liberating and contextualizing data on the production side. It has delivered value through automated contextualization and hybrid solutions involving both ML and physics-based modeling. But the data problem runs the full length of the value chain. To extract maximum value, and to set all the players along that chain up for future success, the company needs to deploy its technology, solutions, and expertise so that they include well delivery.

Well delivery data is different, more complex, and even more locked down than production data. A simple analogy would be the difference between digitalizing the construction process and digitalizing a house that has already been built.

The construction process involves a plan that includes many uncertainties and, naturally, changes/adapts along the way. A built house rarely changes, so it is more about monitoring something that is relatively fixed. Digitalizing an ongoing process, particularly in the extreme conditions associated with drilling and wells, takes the challenge to the next level.

Beyond the more difficult challenge, the company sees a corollary increase in both potential value and the speed at which that value can be realized.

The company’s experience in production has taught it to tackle digital transformation “stone by stone,” one use case at a time. This strategy maps exactly onto the practicalities of liberating data and putting it through a so-called contextualization pipeline. The most potentially valuable use cases require data from several separate systems. By addressing each use case in turn, you can select the data relevant to that case and liberate it, an exercise which is rarely simple. However, once that data has been liberated and collected in one place for contextualization, it is available for future use cases, reducing the time to value repeatedly.

One of the main reasons so many digitalization use cases fail is that data scientists and data engineers have to spend 80% of their time getting access to the right data and linking it together manually. Automated contextualization cuts through that wasted time so that teams can focus on finding and creating physical and data-driven solutions instead.

Contextualization is the process of identifying and creating relationships between data to mirror the relationships that exist between the objects generating that data in the physical world. By connecting all industrial data sources (sensor data, maintenance information, 3D models and more) it is possible to create a standardized industrial data model, enabling users to query for data using meaningful semantics.

In other words, once data has been placed in context, workers at every level of well delivery can solve the use cases that mean the most to them, quickly and efficiently and with an eye on future scalability.

Industrial use cases fall along a spectrum of increasing complexity and potential value, from making data available to getting active advice to automating control.

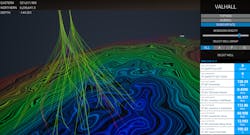

Organizations can achieve instant value by making data available to their teams in the form of insightful visualizations. One of the earliest use cases the company worked with was based on visualizing well construction data. High-quality data is critical to sound decision-making. Fast, accurate visualization of contextualized data allowed the right people to find obvious quality issues, such as location references and other data gaps, and to fix those issues in the source systems. This also enabled the continuous monitoring and improvement of data quality, increasing the odds of success for all future, related digital initiatives.

The company is also working on use cases for well planning, well operations, and reporting.

Embracing the well delivery plan and execution phases into a standardized and structured data-driven ecosystem saved time and costs and enabled automation.

Cognite Data Fusion uses APIs to make it easy to find, share, and store data, enabling increasingly efficient well workflows performed by multiple third parties. The technology implements a standardized phase breakdown, including realistic logistics and detailed operations information, from high-level well planning to machine instructions. With this data structured in context with all other well-related data, engineers can set up rules to trigger alarms and get active advice based on real-time data.

Eventually, this digital foundation would also support physical simulations and machine learning-based instructions enabling drilling automation.

Standardization in data handling will also be critical to the digital transformation of subsurface beyond wells. Finding data is primarily important, which is why the company supports the Open Subsurface Data Universe. At the same time, it is thinking beyond pure search, pushing toward the advanced solution of contextualization of the whole value chain.

This would enable intervention workflows that require well construction data, completion data, integrity data, lessons learned, real-time data, and production data set up with streamlined integration to other systems. The same is true for advanced real-time analytics that require data from multiple sources, using both physical models and machine learning models to achieve the deepest operational insight.

Such a comprehensive digitalization effort will, of course, also require subsurface companies to share the tough-but-essential work of setting up for data handling. This includes defining standardized data structures, data definitions, and any other part of the digital process that does not need to be proprietary. These elements contribute to a digital foundation that will elevate the group. Everyone who chips in can subsequently increase their own competitive advantage in other ways, empowered by clean, easily accessible data, and increased insight over their own operations.

The future of well delivery, like the industrial future as a whole, is digital. The sooner we work together to deploy existing technology to solve our problems, the sooner we progress to a state that allows for greater creativity, productivity, and profit. Data, accessible in context, is the key. •

About the author

Dr. Per Arild Andresen is vice president Drilling & Subsurface Solutions at Cognite. He has more than 20 years of software development, product development, analytics, and management experience within the oil and gas industry. He holds a master’s degree in Industrial Chemistry from NTH in Trondheim, and a Ph.D. in Petroleum Technology from the University of Bergen.