CRP Subsea secures deepwater contracts offshore Brazil, Angola

Offshore staff

LANCASHIRE, England — CRP Subsea, an AIS company, has secured a contract with an energy technology company to supply its distributed buoyancy modules (DBMs) to a deepwater oil field project in the presalt Santos Basin offshore Brazil.

CRP Subsea’s DBMs will be utilized on a flexible production riser transporting oil from the subsea facility to the FPSO vessel above.

Specifically engineered, CRP says the DBMs will establish a dynamic subsea lazy wave configuration to mitigate the top tension on the FPSO. They feature a high-capacity compliant internal clamp, designed to ensure controlled and uniform circumferential clamping pressure around the riser. This is designed to maintain the position of the DBM as well as eliminate the risk of pipeline damage, contributing to the prolonged lifespan of the field.

Manufactured at CRP Subsea’s manufacturing facility in northwest England, project engineering works are set to begin imminently, with delivery scheduled for June this year.

Deepwater project offshore Angola

In addition, CRP Subsea was awarded multiple contracts last month by a major oil and gas original equipment manufacturer to supply four of its solutions to a deepwater oil and gas field offshore Angola.

CRP Subsea’s integral buoyancy modules will be attached to two dynamic umbilicals to establish lazy wave configurations. An integral compliant clamping technology will be used to ensure a uniform clamping pressure around the umbilicals, thereby eliminating the risk of damage to them, CRP said.

Additionally, hold back clamps will be provided to support the main dynamic umbilicals, ensuring that they hold in position. Uraduct also has been chosen for subsea crossing protection during the laying of the umbilicals on the seabed. CRP says Uraduct is designed to give the umbilical’s superior abrasion and impact resistance as well as reduces the risk of dropped object damage.

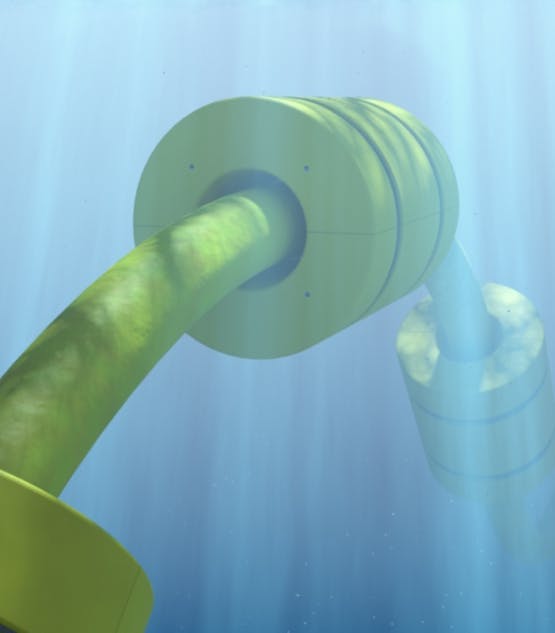

Finally, bend stiffeners (pictured above) will be engineered to cater to the requirements of the umbilicals where they connect to the FPSO vessel.

Manufactured at CRP Subsea’s manufacturing facility in England, project engineering works were scheduled to begin soon, according to the mid-December 2023 news release. Final delivery is expected in the second quarter of this year.

01.10.2024