New statistical data can help pinpoint pipeline decommissioning costs

Editor's note: This article first appeared in the March-April issue of Offshore magazine. Click here to view the full issue.

By Mark J. Kaiser, Louisiana State University

In the final part of this series, cost statistics for pipeline decommissioning in the shallow-water (<122 m, <400 ft) Gulf of Mexico are described. The summary statistics and unit cost described here are based on cost estimates performed by BSEE and reported on the BSEE Online Query System. These cost estimates are based on statistical methods, work decomposition methods, and possibly combinations of the two.

Probabilistic vs. deterministic cost

BSEE reports two types of cost estimates, probabilistic (P50, P70, P90) or deterministic, for each decommissioning stage. The method applied is not disclosed, but it is reasonable to assume that probabilistic cost estimates are made where there is an adequate sample of operator-data, while deterministic approaches are applied where probabilistic descriptions are not feasible or possible, namely for small samples or specialized and diverse operations.

For most shallow-water wells and platforms, probabilistic (P50, P70, P90) cost estimates are reported, and in Parts 2 and 3 of this series, results for P50 cost statistics and functions were described.

All BSEE pipeline decommissioning cost estimates are reported in deterministic terms, probably an indication of the wide variation in reported data, which is not surprising considering the nature of the operations and the diversity of pipeline types.

The use of a single statistic (most likely the average or median of operator data) is classified as deterministic, although in principle other methods such as work decomposition approaches, could also be applied.

Pipeline type

Pipelines are used to transport raw and processed production between wells and platforms, between platforms, and from platforms to shore. They range in size from less than 1 inch to 54 inches in diameter, and may be less than a hundred feet to several miles long.

Pipelines transport bulk (raw) streams from the wellhead, processed oil and gas, water, and various other products. Described by segment number, a pipeline segment originates at one location and water depth and terminates at another location and water depth.

There are a few dozen product codes applied but only a handful are important in shallow water. Bulk gas (BLKG) and bulk oil (BLKO) represent full well stream production from gas wells and oil wells, respectively.

After first processing, pipelines are classified as gas (GAS) and oil (OIL) and these are export line designations.

Lift (LIFT) lines are used to send natural gas to a wellbore to help lift oil to the surface and are common in shallow water.

All the other product classifications are used less frequently with much less installed mileage such as gas and condensate (G/C), gas and oil (G/O), and oil and water (O/W) pipelines. If trace amounts of hydrogen sulfide are present in the streams, an H is affixed to the label; e.g., GASH, OILH, G/CH, G/OH.

Cost factors

In accord with BSEE regulations, a pipeline may be abandoned in place if it does not constitute a hazard to navigation or commercial fishing operations and does not unduly interfere with other uses in the OCS. Pipelines abandoned in place need to be flushed, filled with seawater, cut, and plugged with the ends buried at least 1 m (3 ft) below the mudline.

Pipeline abandonment cost is determined by the water depth involved, the length and type of the pipeline, the number of endpoint connections, and whether the pipeline terminates at a subsea tie-in or another platform.

Pipelines need to be purged and cleaned and one factor influencing pipeline decommissioning cost is the volume of fluids used to clean the line, which can be estimated by the diameter of the pipe multiplied by the length of the line.

Water depth is another factor in the cost of pipeline abandonment operations because water depth places a physical restriction on the amount of time divers can safely work, and divers are often used in shallow water to make pipeline cuts.

Pipelines transiting sand resource areas may require full removal so as not to interfere with other resource users, and removal operations are much greater than leave-in-place options.

Cost statistics

All BSEE pipeline decommissioning cost estimates are reported in deterministic terms, probably an indication of the wide variation in reported data, which is not surprising considering the nature of the operations and the diversity of pipeline types.

The status of a pipeline is not expected to impact the cost of decommissioning since whether the pipeline is active or out of service, the close-out activities remain essentially the same, and even though starting points of the operation may be different, distinguishing differences in cost at this level of granularity are usually not possible or relevant.

This is borne out statistically, to some extent, since each of the four main status categories have quite similar average decommissioning cost by segment and vary in value by only a few percent from each other. Status is not considered a useful attribute for cost estimation.

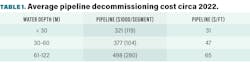

Pipeline decommissioning cost statistics are summarized in Table 1 by segment and footage. In aggregate, average costs increase from $321,000 per segment in water depth <30 m, to $377,000 in water depth 30-60 m, and $498,000 in water depth 61-122 m.

Normalizing by length, a similar increasing trend emerges, from $31/ft in water depth <30 m, to $47/ft in water depth 30-60 m, and $65/ft in water depth 61-122 m.

Costs grouped by product type is also insightful (Table 2). Five product categories are employed and the data shown include the sample size (number of segments), total distance in footage (1000 ft), and estimated decommissioning cost of the sample ($ million). Unit costs are depicted by pipeline footage ($/ft) and segment ($/segment).

Bulk oil and gas, oil and gas, and lift constitute most segment counts, footage and cost in all water depth categories, but the unit cost show no obvious trends across water depth category or product type, and no hypothesis or explanation are offered on how the BSEE cost data was prepared and evaluated except that the use of simple averages or median values were likely employed.

In water depth <30 m, unit cost depicted range from about $29/ft to $68/ft, while in 30-60 m, cost ranged from $37/ft to $52/ft, and in 61-122 m, from $49/ft to $75/ft. Note that unit cost per product type do not necessarily increase in increasing water depth, but the overall ranges (min and max value) tend to increase.

Cost per footage is likely a better statistic than segment cost, unless segments are relatively small. One might expect bulk lines to cost more to decommission than export lines, but the statistical evidence is mixed and inconclusive.

Lift lines, which are similar to gas (export) lines but much smaller, show no consistent trends.

In total, for all product types and segment counts, unit cost increase with water depth.

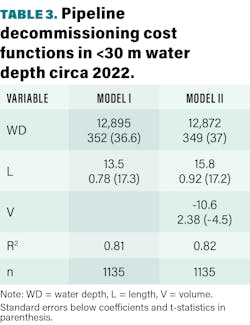

Regression models were built using water depth, segment length, and volume (to include diameter variation), and although the results are encouraging (Table 3), we believe more work is needed on the input end (i.e., BSEE data processing) before further examination of the output data is warranted.

About the author

Mark J. Kaiser is Professor at the Center for Energy Studies, Louisiana State University, Baton Rouge, Louisiana.

About the Author

Mark J. Kaiser

Center for Energy Studies

Mark J. Kaiser is Professor at the Energy Institute at Louisiana State University. His research interests cover the oil, gas, and refining industry, and relate to cost assessment, fiscal analysis, infrastructure modeling, and valuation studies. Kaiser has led several studies and published extensively on decommissioning in the Gulf of Mexico. He holds a Ph.D. from Purdue University.