Global oil and gas PPE market set to grow to $9.5B by 2028

By Kapil Garg and Shalom Divekar, MarketsandMarkets

Rising awareness about the importance of workplace safety and stringent regulations in developed countries is promoting the use of personal protective equipment (PPE), which is used to provide protection against health risks in hazardous work environments

According to the Respiratory Protection Standard, 29 CFR 1910.134, of the US Occupational Safety and Health Administration (OSHA), it is mandatory for employers to have a complete respiratory program. Workers that wear respiratory protection must participate in written respiratory programs and follow OSHA’s guidelines, which include medical evaluation, respirator fit testing, and training.

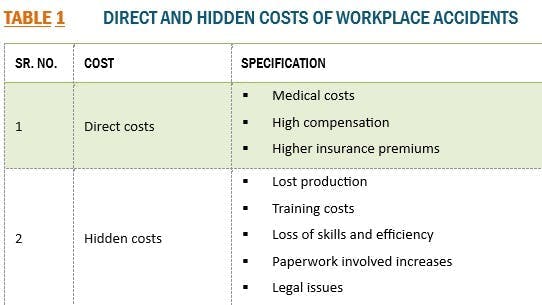

According to OSHA, workplace injuries have witnessed an increase each year in the US. OSHA reported that workplace eye injury costs an estimated $300 million per year in medical treatment, lost productivity and worker compensation. Data from the US Bureau of Labor Statistics also supports the fact, stating that most of the injured workers were not wearing PPE at the time of the accident. A few losses, both direct and hidden costs, occur when a workplace accident occurs. Direct costs are realized at the time of accidents, whereas hidden costs are realized post-accidents.

High energy demands

The increasing population influences the burgeoning demand for energy worldwide. According to the UN World Population Prospects, the global population is expected to rise from 8 billion in 2022 to 8.5 billion by 2030. Various energy sources, such as thermal, nuclear, renewable, oil and gas, and electricity, are required to meet the growing energy demand.

Regions with high energy demand plan to increase offshore oil and gas production. As shallow-water fields mature, companies are turning their focus to deep and ultradeepwater opportunities, leading to investments in offshore and subsea activities. Oil and gas companies are expanding their search for new reserves, particularly in ultradeepwater areas, including the Arctic. The US Geological Survey’s Circum-Arctic Resource Appraisal in 2008 estimated large amounts of oil and natural gas in the Arctic, with the region holding significant undiscovered reserves. This has increased interest and investment in the area, particularly in offshore drilling services.

More offshore operations results in more workers, thus the need for companies to implement HSE strategies and put plans in place to ensure worker safety.

Hazardous environments

The oil and gas industry faces different types of risks and hazards, thereby giving rise to serious accidents that might adversely impact people, assets and the environment. Safety is the most critical concern in the oil and gas industry. However, the lack of proper safety systems in this industry may lead to production loss, stress on affected components and systems, and hazards during system restoration.

Oil and gas drilling and servicing activities are undertaken in hazardous environments, which mandate the installation of safety systems for such activities. Oil rig activities can be hazardous and lead to major accidents, with potentially severe consequences for workers' lives and health, environmental pollution, direct and indirect economic losses, and the deterioration of energy supply.

The inherently hazardous nature of oilfield operations necessitates rigorous safety measures, and digital technologies can offer a robust framework to enhance safety protocols. Industrial safety systems are designed to eliminate or reduce the after-effects to a minimum level if any emergency situation arises at a facility or plant. Real-time monitoring through sensors and IoT devices allow for immediate detection of anomalies or potential hazards, enabling swift response to mitigate risks.

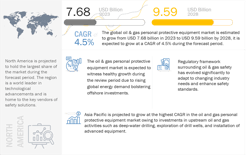

Regulatory framework

The regulatory framework surrounding oil and gas safety has evolved significantly to adapt to changing industry needs and to enhance safety standards. Governments and regulatory bodies worldwide are placing greater emphasis on pipeline integrity and the prevention of incidents. This includes developing and implementing more stringent regulations, bars and guidelines governing offshore inspection and monitoring practices.

In the oil and gas industry, standards such as IEC 61508, IEC 61511, and the Norwegian Oil and Gas guideline 070 provide recommended frameworks for implementing industrial safety. Additionally, there is an increasing focus on risk-based approaches, incorporating advanced technologies and data-driven methodologies to assess and manage offshore infrastructure integrity. Advanced analytics and predictive maintenance further contribute to proactive safety measures by identifying potential equipment failures before they occur. Additionally, the use of automation and robotics reduces the need for human intervention in high-risk tasks, minimizing the exposure of personnel to dangerous environments.

The evolving regulatory framework aims to foster a proactive and systematic approach to safety, ensure continuous improvement, and reduce the potential for failures and environmental impacts.

Market outlook

The global oil and gas PPE market is estimated to grow from $7.68 billion in 2023 to $9.59 billion by 2028, at a CAGR of 4.5% during the forecast period. This growth can be mainly attributed to rising global energy demand, especially in emerging economies, which has spurred offshore exploration and production investments. Offshore reserves frequently hold substantial quantities of oil and gas, rendering them appealing for addressing the growing energy requirements. According to S&P Global Commodity Insights, there is an increase of 11% in spending on exploration and production in 2023, with a 20% increase in offshore activity. In addition, governments and energy companies are increasingly recognizing the potential of offshore fields to meet rising energy demand.

Workers involved with oil and gas operations are exposed to serious life-threatening hazards such as harmful chemicals, gases, vapors and fumes as well as the risks of falls, burns, fires, explosions and vehicle accidents. In offshore drilling, there are increased risks of blowouts and the release of hydrogen sulfide and formaldehyde, threatening those working at such locations. Additionally, workers are exposed to high risks of noise-related hearing loss. These risks emphasize the need for specialized PPE in the oil and gas industry.

To prevent workplace incidents, associations such as OSHA, the Information Security Education and Awareness, the National Fire Protection Association, and the National Safety Council mandate workers in the oil and gas industry wear PPE such as helmets, gloves, footwear, protective clothing, safety glasses, ear plugs and respiratory guards.

About the Author

Kapil Garg

Kapil Garg is the practice lead (manager) of the Energy & Power Practice with MarketsandMarkets.

He has more than 13 years of experience in the energy, chemical and material industries. He has worked on various consulting and business research projects in areas such as digital oil field, renewable energy, environmental technology, paints and coatings, construction chemicals, and others. He holds a bachelor’s degree in petroleum engineering from Pune University.

He can be reached at [email protected].

Shalom Divekar

Shalom Divekar is a lead business analyst (assistant manager) of the Energy & Power Practice at MarketsandMarkets.

He has a total work experience of more than seven years. His experience pivots around verticals such as oil and gas, power, and renewables. He has worked extensively on research and consulting projects for oil and gas majors, power equipment manufacturers, utilities and energy management companies, and he has helped them navigate the energy transition landscape. He graduated from the University of Pune with a focus on geology, and he holds a postgraduate degree in petroleum technology from the University of Pune.

He can be reached at [email protected].