Real-time production management system gives advanced warnings, improves decision making

Jo Elder, Knut Erik Spilling - SPT Group

In comparison to topside processing facilities, a subsea production system (wells, flowlines, and risers) has little instrumentation. At best, there may be bottomhole pressure and temperature instruments in each well together with measurements at the wellhead choke valves and at the top of the riser.

Unfortunately, there is a lot going on between the sand-face and the topside’s manifold. There are complex hydraulic phenomena, and the system dynamics are significant.

So how do we make qualified operational decisions with so few measurements?

Traditionally, the problem is overcome by using highly conservative operating procedures. Even then, experienced operators can find system responses counter-intuitive and, occasionally, an upset event causes sustained period production drop.

Dynamic, online production management technology is making the pipeline “transparent”, to provide advanced warning of abnormal situations and to allow for better, less conservative, decisions. This technology is changing the industry’s approach to operating multi-phase production systems.

The drive to find replacement reserves increasingly pushes the offshore exploration and production industry into deeper water. For such developments, the robust and reliable operation of the production network is crucial to commercial success.

Amongst the engineering challenges are the fluid flow, heat transfer, and production chemistry characteristics that give rise to formation of hydrate or wax solids at low temperature and unstable, slugging flow regimes. Normally covered by the term “flow assurance”, these matters are not exclusive to deepwater, but a number of factors increase the deepwater risks.

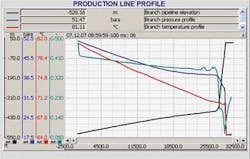

During the design of deepwater developments, therefore, significant effort is made to understand the conditions within the production network. Computational dynamic, multi-phase pipeline flow models show engineers the physically measurable (e.g. pressure, temperature and flowrate) conditions at all points in the system as well as un-measurable variables such as liquid accumulation or chemical concentrations.

SPT Group’s edpm product is now extending design stage understanding into the online, real-time environment. Over the last three years, the company has developed around 15 of these online production management systems worldwide. The demonstrated benefits include less downtime, lower OPEX, and higher production rates.

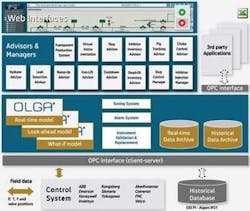

Efield dynamic production managment (edpm) is an online production support system using first principle mathematical models of the production network. SPT Group’s OLGA software is the simulation engine, and multiple sets of OLGA models run in edpm across different time domains.

The system is connected directly, using standard OPC protocols, to the control system or, in some cases, a historical database (e.g. OSI PI). At frequent control system scans, information is updated so the models working in real-time mirror real-life conditions. Virtual instrument readings for both measurable and un-measurable variables are calculated in the production system to supply a full picture of the system conditions.

As well as making the pipeline “transparent”, the product has Advisors and Managers to simplify and automate key operations; giving operators more time to concentrate on other value adding activities. They apply knowledge-based functionality and often deliver a higher level of decision making, by using transparent pipeline parameters, than could be achieved by an operator responding to plant measurements. In some Advisors and Managers, the future is predicted using faster than real-time models (look-ahead mode).

In addition, if the operator or engineer wants to test the impact of a non-standard set of actions, for example when planning a new alignment of wells to the flowlines, the faster than real-time “what-if” mode provides a manually driven simulation environment.

Information must be communicated effectively to realize its value. Some users choose to return key variables, such as a pig position during scrapping operations or the required chemical injection rate, back to the control system for display at the operator interface. The majority of information is, however, presented in a dedicated graphical user interface (GUI). Using thin client technology and Internet Explorer, the GUI is accessible on any Windows-based PC operator station, whether in an onshore support center, at the production engineer’s desk, etc.

Application

User feedback shows the benefits of online production support systems can be summarized simply as: providing advanced warning of abnormal situations, enabling proactive control of the production network, and allowing better and faster decision making.

The ways in which benefits are delivered vary with each application, since each development faces a unique set of challenges. Even with customization, a payback time of less than three months has been reported and substantial savings have been identified.

Deepwater edpm project highlights:

•BP Na Kika Advanced Warning System- Location: Gulf of Mexico

- Online: 2005

- System integration: Honeywell Experion with OSI PI Historical Database

- Gas lift: The gas lift flowrate required to eliminate severe slugging and the rate subsequently required to maintain stable flow is calculated. The latter usually is much less than the first and, therefore, the system advises operators to reduce gas injection once the initial dynamic disturbances have been eliminated.

- Cooldown: Low temperatures on shut-down risk hydrate formation. Inhibitor or dead oil displacement may be used to prevent problems. Edpm calculates the cooldown time based on the actual process conditions so that operators can choose between hydrate injection and dead oil displacement operations. Previously, inherently conservative recommendations from the design analyses were used.

- Field of the future: The system has been shown to fit with BP’s digital infrastructure, linking with and complementing other Field of the Future applications such as reservoir performance managers and topsides optimizers.

- Additional functionality: Transparent Production System and Virtual Metering.

- • Chevron Lobito Tomboco Pipeline Management System

- Location: Offshore Angola

- Online: March 2007

- System Integration: Yokogawa Centum CS3000

- Alarm system: The edpm alarm system monitors two key variables that are not measurable; the liquid hold-up at the bottom of the riser advises on the formation of a slug in the riser, and the margin from hydrate variables report the risk of solid formation in jumpers, wellbore, and flowlines. An alarm triggered from the Virtual Instrument (real-time model) is shown in the GUI and a lower level signal (Alert or Warning) is activated if the “look-ahead” or “what-if” modes predict a future problem. Excessive separator liquid level and pressure excursions also are monitored in look-ahead and what-if modes.

- Online tuning: The system is equipped with online tuning in case the predictions of the real-time model drift from actual conditions due to changes in the well boundary conditions. Different tuning options are available and these are activated, if required, by the operator or the support engineer.

- Additional functionality: Transparent Production System, Virtual Metering, Gas Lift Advisor (as above), and Cooldown Tool (as above).

- • StatoilHydro/Shell Ormen Lange Pipeline Management System

- Location: North Sea, Norway

- Online: October 2007

- System integration: ABB Industrial IT

- Leak and Blockage Detection/Locator: The system applies continuous online monitoring from a parallel real-time model. The deviations between simulated behavior and field measurements are monitored and a leak position and magnitude is calculated to account for any discrepancy. The operator is alerted through the alarm system.

- Pig tracking: Edpm advises on the current velocity, the average velocity, and the location of the pig, together with the remaining pigging time. Different pig types are available to reflect real-life operations.

- Additional functionality: Transparent Production System, Virtual Metering, Hydrate Advisor, Ramp-up Advisor, Automatic Start-up Tuning, and Look-back Tuning.

The Ormen Lange PMS is an integrated part of the Flow Assurance System delivered by FMC.

eField Dynamic Production Management (edpm) and OLGA are registered trademarks of SPT Group. For more information, please visitwww.sptgroup.com.