COMPOSITE RESEARCH: Enclosed fiber-reinforced plastic tubes provide buoyancy for Spars, TLP units

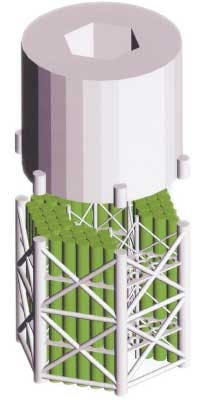

A system of floating or tension-moored offshore production units that use a central deep-draft hull consisting of enclosed fiber-reinforced plastic (FRP) tubes has been developed by Fiberglass Structural Engineering, Inc. (FSE).

The tubes are lightweight and corrosion-resistant, and efficiently use space and material. A non-exclusive licensing agreement with Shell International Exploration and Production for this patented technology is in place.

With the expanding need for floating offshore drilling and production facilities, the industry is increasingly interested in cost-effective, reliable and low-maintenance flotation systems. The fiber-reinforced plastic (also known as FRP, GRP, or composite material) flotation tube concept has undergone initial feasibility studies with these goals in mind. Early results show significant cost savings and a reduction in weight, according to the developers, compared with conventional steel hull construction techniques.

Using a Spar, for example, the vertical FRP tubes with a sealed top press against the keel of a shortened conventional spar hull at 80-100 ft below the water's surface. On the tubes are steel bumpers that press laterally against a rigid steel structure. The tubes and steel structure together comprise a flotation module located between the upper hull and the truss structure extending to the bottom ballast tank.

Pressure adjustment

The tubes are open at the bottom and internally pressurized with air to provide buoyancy. Buoyancy is adjusted by varying the internal air pressure. Because they have open bottoms, the tubes experience no external hydrostatic loading and no axial tensile loads from the internal pressure. Therefore, they are designed primarily for hoop tension, which in turn minimizes the required wall thickness. The steel tubular components of the flotation module are sealed to provide additional buoyancy.

According to the developers, the benefits of the FRP system are as follows:

- Reduced capital expenditure: Preliminary investigation demonstrated a cost savings of 10-20% using flotation tubes versus conventional steel construction.

- Reduced operating expense: FRP is substantially inert in seawater and needs no protective paint coat, cathodic protection, or sacrificial anodes.

- Weight savings: Preliminary estimates show that, considering the weight of the FRP tubes and structural steel elements in the flotation module, and considering the total displacement of the flotation module, the density is 6-8 lb/cu ft displacement.

- Uses proven/conventional design manufacturing: No new materials, design methods, or manufacturing methods must be developed to produce FRP flotation tubes. Qualified fabricators are in place, and materials and manufacturing capacity are plentiful.

- Modular design: Tube length is varied to meet design buoyancy needs. For example, 10-ft diameter tubes are suitable under a 125 ft plus diameter hull. This provides approximately 40,000 kips net buoyancy contribution from the flotation module itself.

- Reduced construction schedule: The FRP tubes are manufactured off-site, concurrent with truss/hull construction. They are deli-vered to the fabrication yard for final assembly. FRP fabricators estimate that 9-12 months are required to produce the tubes.

- Adaptability: Flotation tube technology readily adapts to provide flotation for truss or caisson Spars, tension leg platforms, risers, mooring lines and tendons, mid-water buoyancy elements, and as retro-fit flotation for existing structures.