FPSO monitoring technique improves damage tracking and prevention

Offshore contractors are interested in the feasibility of installing permanent monitoring systems for floating production platforms. These structures are expected to be at sea for long periods (typically 20 years) without being brought to dry-dock for maintenance.

In recent years, emerging trends have created a favorable context for such a study. These include deeper offshore activities, the conversion of old tankers for use as FPSOs, the financial impact of interruptions to production using these platforms, increased awareness of safety and environmental issues, and the general insistence on "real-time" monitoring solutions.

Problems arise from the local nature of crack initiation in a large and complex structure such as a floating platform. On FPSOs, most fatigue cracks are located in the side shell, more specifically in the connection of longitudinal girders to transverse web frames and in the central area of the ship close to the middle cross-section. Heavy concentrations of cracks are located in the area below the waterline.

Fatigue damage is caused by:

- Vertical and horizontal wave-induced bending moment and outside water pressure on the side shell in the area of fluctuation of the waterline

- Loading and unloading of the FPSO

- Fabrication imperfections.

Cracks occur typically at welded joints, but may also appear in other areas prone to build-up of stress, such as notches, openings, shackle holes, and incorrectly finished welds. Moreover, it is difficult to assess if a crack is approaching critical length when rapid and unstable growth occurs.

Progress in numerical simulation is enabling longer-term prediction of global structural behavior and the assessment of potential stress and damage, but this process requires that historic internal and external loading conditions are known with good precision. In the case of old (converted) structures, two main approximations have to be made when using such a simulation. But in the absence of a permanent monitoring system onboard, the load applied on the structure – and the associated structural damage – remains only roughly estimated.

If there is a lack of historical damage on the boat prior to its conversion to an FPSO, a theoretical "zero point" can be assessed. With the development of dynamic monitoring approaches, it becomes possible to detect sufficiently early a change of measurable properties associated with localized damage and to pinpoint this damaged area.

Over the past five years, Principia, based in La Ciotat, near Marseille, has developed hull-monitoring systems for the French Navy, LNG tankers, and fast-ferries. The company's technique can be adapted to employ either conventional strain gauges or optical fiber-based (Bragg) technology, or a combination of both.

The main advantages of the Bragg system are:

- Long-life duration without the need for any human intervention (more than 20 years)

- Potential to control strains, temperatures, and pressures

- Multiplexing technology that allows more than 40 sensors on a single fiber

- Time saving in installation

- Simplified network based on a unique cable

- Large scale of sensor sampling for Hz to KHz

- No need for anti-deflagration protection, thanks to optical technology.

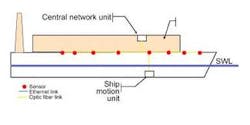

The sketch shows an example of such a system. Digital and analogue systems can be added, allowing the addition of various sensors. All data is centralized on a PC for real-time and delayed use. Alarms can be programmed according to pre-defined levels.

The experience gained by Principia on ship monitoring can be adapted easily to an FPSO. The system will encompass a numerical mock-up, allowing computation of the FPSO's response to sea and cargo loading. This response will be linked to the ship's motion and the sea state, allowing predictions on a future condition statistics basis. The monitoring system allows predictions to be calibrated.

Local stresses on a pre-defined location can be obtained by using the numerical mock-up, leading (through counting) to detection of the associated damage. In the case of a new structure, the system can also predict the remaining life span. A facility can be added to survey larger critical areas, or to detect a localized rapid change, and this feature can be integrated into the monitoring system.