Laser-based gas sensors keep moisture out of pipelines

Because natural gas produced at the wellhead often contains contaminants, including water, it must be cleaned and brought to “Pipeline Quality” before it can be safely delivered to high-pressure, long-distance pipelines. Natural gas that is not within certain moisture levels can cause operational problems, pipeline corrosion and long-term deterioration, and even the possibility of pipeline ruptures. Various processes are used to remove this water vapor.

In the past, many natural gas producers, processors, and distributors have relied on direct contact, surface-based electrochemical and crystal sensors to measure residual moisture in gas. However, that technology may produce false data that results in unwarranted shut-ins and/or contaminated gas getting through lines.

“If we were to shut-in a producer due to a false moisture reading, millions of cubic feet of gas could be delayed and possibly incur unnecessary dehydration costs,” says Melvin Yancey, a field measurement technician at the El Paso Natural Gas Co.’s San Juan District in the Four Corners Area.

To avoid those possibilities and to meet quality standards of pipeline gas, El Paso has installed new laser-based sensors where each of its 16 major producers in the San Juan area joins the pipeline. Each producer can monitor El Paso’s gas analyzer readings by capturing the electronic signal from El Paso’s unit via a SCADA system and viewing the readings in the producer’s control room.

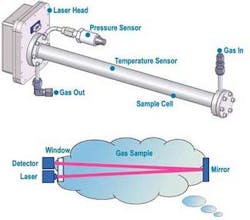

Marketed under the SpectraSensors brand, this is an advanced and trustworthy monitoring technology - a tunable diode laser (TDL)-based technology developed at NASA’s Jet Propulsion Laboratory at Caltech that is effective in detecting contaminants in natural gas. Manufactured by SpectraSensors Inc., a developer and producer of optical-based gas sensors, the reliable, “bread box-size” gas analyzer provides non-contact measurement of moisture, carbon dioxide, and other corrosives in natural gas pipelines.

Tunable laser-based gas sensors are fast, accurate, and flexible. They are also cost effective. While initial purchase price is somewhat higher than surface-based gas sensors, even conservative evaluation of this technology indicates that maintenance saving alone can provide a return on investment in a short time.

For example, transmission pipeline operators traditionally rely on electrochemical sensors as gas analyzers to monitor moisture. These sensors use a coated surface, and a higher electrical capacitance across the surface indicates higher water content. However, these capacitance sensors are susceptible to contamination by glycols or amines in the gas, which can cause exaggerated readings or a failure to detect.

An erroneously high reading could force a temporary shut down of the pipeline, costing thousands of dollars. The gas producer may choose to over-process the product to ensure it is within the tariffs imposed by the pipeline operator. Because the laser-based gas analyzer responds quickly and provides a reliable measurement that will not drift, it can be used in a closed loop to control the blending of dry and wet gas, allowing the producer to optimize costs by staying within the tariff.

Because a laser system never contacts the contaminants, the laser-based gas analyzer has lower maintenance and operations costs. Studies show the cost of operating and maintaining “conventional” electrochemical sensors can reach an annual expense exceeding $50,000 per unit for labor, recalibration and rebuilding, back-up sensor heads, as well as unnecessary gas dehydration and tariffs. The laser-based gas sensors avoid these costs.

This technology is used by natural gas producers in three locations: the Gulf of Mexico, the North Sea, and Vietnam. Plans are to add users in more offshore locations.