Advanced digital solution will monitor two submarine cables offshore Saudi Arabia

Ahmed Sami Khaiyat, Saudi Aramco

Abdulmuti Ruhaili, Saudi Aramco

Bård Johan Svensson, Nexans Norway

In offshore oil and gas fields, submarine composite cables are the primary means of transmission of power to offshore oil and gas producing and processing facilities. The healthiness of these cables plays a vital role in efficiently operating and maintaining a robust power supply system. Continuous monitoring of submarine cables is one method of achieving the robustness.

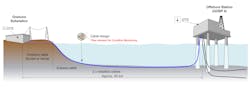

In line with the Saudi Aramco’s technology deployment strategy, the Marjan Offshore Gas-Oil Separation Plant-4 (MOGOSP-4) development project is deploying an advanced digital solution to monitor the condition of two 230kV composite submarine cables with a total length of 90 km each, including a 72-strand fiber optic (FO) cable. Upon installation, these cables will be recorded as two of the longest submarine cables ever installed in the region. They will deliver approximately 260 megawatts of power to the Marjan offshore field. The deployed digital solution is represented by the distributed temperature sensing (DTS) and real-time temperature rating (RTTR) system.

DTS and RTTR are integral monitoring systems that utilize a dedicated fiber optic strand as a continuous-applied sensor along the composite submarine cables. This is in lieu of a huge number of discrete sensors scattered along the cables. The FO strand, used as the sensor, is activated through a laser signal originated from a component of the DTS, called the interrogator. The signal propagates back and forth to the interrogator for which a raw temperature profile of the cable conductor is created in the DTS based upon the signal variations.

Another type of system, Distributed Acoustic Sensing (DAS), operates in a similar fashion as a DTS, but it analyses the response from the fiber differently. It detects and stores all vibrations in the cable, such as when an anchor hits the cable.

In contrast, an RTTR is a software-based system installed in a server where calculations are performed through programmed algorithms to compute the temperatures of the cable conductor as a function of distance. The RTTR can also predict and forecast the temperature of the conductor for a short period of time using the data stored in DTS.

Moreover, the RTTR and DTS systems are integrated into a power management system and power system automation which will provide a human-machine interface for monitoring and controlling the electrical parameters, or generating alarms to maintain the desired outcome of the power network.

DTS and RTTR systems offer many advantages to offshore facilities. Through real-time temperature sensing, a complete monitoring of the temperature of the power conductor within the cable is achieved at any time. Also, with this solution, the RTTR can identify an electrical fault occurrence where a temperature variance is detected. Moreover, the DAS can detect and locate the mechanical stress that originates from impacts on the cable, or other events that create vibrations. This advantage will reduce the opex cost associated with cable repairs. Such a system can also help the asset operation team identify trends based on the collected data across the life cycle of the cables. These trends can be an advantage in planning major repairs or services.

Saudi Aramco looks forward to analyzing the outcome of this digital solution upon commissioning. The data gathered by this system should enable the asset operations team to improve the design of future long submarine cables and optimize the opex associated with operating such cables. The system will also enable early response to emergency incidents resulting from faults or mechanical damages.