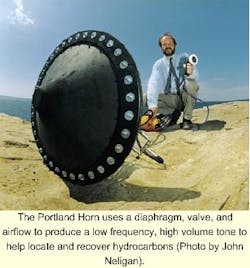

Vibrator used for enhanced recovery, seismic source

When Tim Snape of Abbotsbury Software, a company based in southern England, set out to develop the Portland Horn in the early 1990's, he had in mind a simple device to help divers and their mother ship to communicate. The equipment, resembling a Frisbee at one end, would allow the vessel to call the divers if, for example, a storm were brewing.

The UK Department of Trade and Industry granted the company funding for further development. Soon, the potential for use in finding and extracting more crude oil from marine fields emerged. The device is now being tested by a multinational oil company.

A flow of air in the horn causes an elastic diaphragm to vibrate, but the exhaust air is allowed to escape only through a valve, which produces the sound. When it is used underwater, it generates a low frequency tone with a high volume. By varying the tension in the horn's diaphragm, a change in the frequency of the tone is achieved.

According to the developers, the equipment has major applications in the oil industry where current technology is capable of yielding only about 40% of oil from reservoirs.

- Employed in seismic monitoring, the Port land Horn offers a faster and cheaper alternative to time-consuming acoustic explosions on the ocean floor and computer processing of the data into a three-dimensional model.

- The horn can be used to ease the flow of oil during the extraction process by focusing acoustic energy to produce a shock wave around the wellbore. This is believed to be more environmentally friendly and achieves greater yields at lower costs. But how vibration works to increase oil flow is not yet known. One theory is that it agitates particles in the liquid. More development work and tests are scheduled to refine the product.