Virtual flow metering improves field data

Efficient monitoring, better field management among the benefits

Richard Heddle

John Foot

Hugh Rees

BP

Nearly 10 years ago, BP launched its "Field of the Future" program to bring to reality the aspiration of safely operating assets at the technical limit of efficiency, recovery, and cost. Most of the technologies developed under the program are digital in nature and focus on enhanced surveillance, alerts, and control. The intention was not only to create a portfolio of technologies, but also to advance their deployment across most of the company's operated fields.

One such technology which has been deployed is the Integrated Surveillance Information System (ISIS). This is a browser-accessed online application for the surveillance of entire subsurface systems. A core module integrated with other surveillance tools within ISIS is the Rate&Phase virtual flow metering (VFM) system.

The VFM system estimates the production rates of individual wells using hydraulic models and requires only the instrumentation typically installed on new wells. It enhances surveillance and understanding, making operations safer, increasing production, improving reservoir management, and highlighting opportunities.

Currently more than 300 producer and injector wells in 20 assets across four continents, from the UK North Sea to Angola, and the Gulf of Mexico to Indonesia, have the VFM system. These have been deployed in the past five years and so far have produced far in excess of 10 million well rate estimates. Preparations are on track for the system to monitor first oil of two fields expected to start-up in 2012.

The benefits of the VFM system include:

- The availability of well production rate estimates in near real time allows better understanding of changes to well performance and assists in production optimization

- Daily production reconciliation factors typically are closer to unity than previously, and less effort is required to compute them

- Pressure transient analysis can more accurately estimate inflow performance parameters such as skin because the well rates are known prior to shut-in.

- Engineers can be confident that operation is within equipment integrity limits because of the high-quality rate estimates

- The reliability and consistency of the VFM estimates can alert to inaccurate measurements

- Well testing can focus on wells where performance has changed to reduce both risk and production deferral

- Reservoir management benefits from more accurate allocation of production because this yields improved reservoir simulation models.

The system applies exactly the same procedures that an engineer would follow when calculating rates manually, and uses the same modelling as other petroleum engineering activities within the company, and can be verified manually. The results have been excellent.

Going with the flow

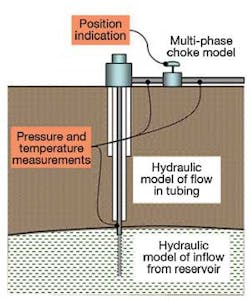

The Rate&Phase VFM system is based on hydraulic models calibrated to past production data. The oil or gas rate is computed so as to honor both the physics and the conditions measured across the well. The components of the well model represent the inflow from the reservoir, flow in the tubing, and flow through the choke. Rate&Phase requires no added instruments beyond those routinely installed on new wells. The system applies to oil, gas and retrograde condensate producer wells, and water and gas injector wells.

Hydraulic well models based on the physics of multiphase flow and calibrated to actual operating data often can extrapolate beyond the envelope of past conditions than systems based on statistical functions generated from operating data.

Where sufficient measurements are available, it is possible to combine the separate model components. Thus, they can, for example, not only infer multiple possible oil rates for the well, but also infer other operating or performance factors such as a phase parameter (watercut or gas-to-oil-ratio [GOR]) and/or a reservoir performance parameter (reservoir pressure or productivity index/skin). Where instrumentation is lacking, the system may only be able to determine the oil or gas rate and the quality of the estimates may decline. Innovative multivariable root-finding schemes have been applied to locate solutions quickly and to handle discontinuities.

As an example, the procedure applied to an oil producer well with known watercut but unknown GOR and reservoir pressure would be to use the tubing model to deduce the oil, gas, and water rates from the change in pressure and temperature in the tubing. The rate can be confirmed using the choke model and then the current reservoir pressure to be estimated by the inflow model (assuming an unchanging mechanical skin).

Model calibration

The system is based on models which incorporate multiphase flow correlations. These require routine revalidation and recalibration when conditions change significantly, or well performance changes. This requires measurement of the oil, gas and water production rates, and so it is necessary to be able to perform this measurement. Typically this requires that the well be routed to a test separator or a multiphase flow meter for a period of time every month or so.

The VFM is often required to estimate rates over a range that extends from near shut-in to maximum flow. Experience shows that the models are only accurate over such a wide range of conditions if data is obtained from multiple tests. The factors commonly adjusted within the models to calibrate the well model are the choke performance curve, tubing friction, and hydrostatic coefficients and the inflow productivity index.

Streamlined system

ISIS provides a browser-accessible interface to most of the subsurface sensor data and surveillance information engineers require to manage the fields. Trends, tables, and the process schematics are pre-configured and customisable to provide rapid access to relevant information, while an events and alerts management system provides 24/7 monitoring of key parameters.

Modules integrated with the Rate&Phase VFM system within ISIS include those to perform pressure transient analysis, manage well testing, and monitor well integrity. Operation of the Rate&Phase and other modules are computationally intensive, and so a service orientated architecture (SOA) has been adopted.

ISIS handles all the data required by the VFM and calls several times an hour for rate estimation for all online wells. A configurable rule-based system within ISIS selects a "composite" rate from the values computed by the hydraulic models. Then, starting at the well rates, ISIS computes the flow along all flowpaths (pipelines, headers, risers, etc.) through to the separator. Finally, the well and flowpath rates are reconciled against all meters in the system to minimize errors and to provide a final field production allocation.

The VFM also calculates other parameters valuable in integrity monitoring such as velocities in the tubing and bottom hole pressure (with correction for friction and hydrostatics below the downhole gauge). All calculation results are stored in the production historian for offline trending and analysis, and for access by any other modeling and reporting systems.

The Rate&Phase Web interface permits remote configuration and management. The system is designed to recover automatically from any exception because it uses modeling software not originally designed for unattended use on servers.

Gulf of Mexico success

In normal operation, the accuracy of production allocation is quantified by a reconciliation factor which is the comparison of the total flow rate from all wells with the fiscal/export flow meters. Without a VFM system, many assets struggle to maintain reconciliation errors less than 10%. Assets with ISIS Rate&Phase typically achieve better than 5%.

The reliability and quality of the estimates allows assets to control well flow rates to minimize vibration and erosion on subsea pipelines and risers. Others are able to minimize the risk of damage to sand screens because the flux through cased and perforated completions is continuously estimated.

Accuracy in Africa

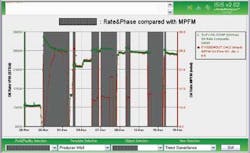

The absolute accuracy of the ISIS Rate&Phase flow estimates for individual wells has been assessed by comparison with flow meter measurements. The excellent agreement over a range of conditions is typical of many wells. (The relevant periods when the well was routed to the seabed multi-phase flow meter [MPFM] are those with the pale background.)

The VFM system has identified two wells in Africa where the GOR or watercut change significantly after start-up. The wells are instrumented with working pressure and temperature sensors downhole and at the wellhead. The data shows how closely the estimated phase parameters match the measured values for periods after start-up. The good agreement has been seen on numerous recent start-ups of these wells.

Conclusion

ISIS and the Rate&Phase VFM system are deployed across BP-operated assets including many major oil and gas fields. Benefits arise from the ability to efficiently monitor well stock, better manage fields, and more accurately allocate production. Production gains come by operating the assets closer to constraints with confidence in the flow rate estimation.

Rate&Phase exploits commonly used modeling, is designed to be easy to deploy/configure, and integrates with other surveillance tools. Acceptance of the system has been hastened because it is not regarded as a black box and all results can be reproduced manually offline. Current production and performance information is readily available and changes over time can be easily trended.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com