Cary Griffin

Ricky Thethi

2H Offshore

With the increasing push toward high-pressure/high-temperature (HP/HT) wells, design requirements for steel riser pipe wall are consequently thicker and pipe joints heavier. In deep and ultra-deepwater, there is a cost-driven preference to use steel catenary risers (SCR) over other riser types. Current SCR pipe manufacturing and welding fabrication capabilities are being stretched, particularly for wells that are a combination of deepwater, high temperature, and high pressure. The industry has been evaluating ways to overcome these obstacles through the qualification of thicker pipe and riser-quality welds.

Thus, the implications of a riser design required to withstand full wellbore pressure for HP/HT projects (i.e. pressures over 15,000 psi/1,034 bar and temperature above 250°F/121°C) must be understood.

The thicker riser pipes required lead to a number of issues, such as reduced inner diameter and flow area, and richer pipe chemistry, which leads to higher hardness levels. Pipeline joining is also affected: There are extensive qualification requirements that accompany thick welds. In turn, these thicker welds are less robust and make sour service challenging. Higher installation tension requirements might also restrict vessel selection. In addition, there is a larger payload on the host. Larger stress joints at the vessel’s hang-off interface are required. Overall, these thicker pipes can also prove more challenging for a reeled installation method.

How far can conventional X65 pipe and welding technology be stretched? Currently, 10-in. outer diameter girth welds are limited to less than 2-in., with qualification programs having been completed for welds of 1.86-in. and 1.9-in. The thickest field-proven production SCR wall thickness is currently 1.65-in. and is designed for sweet service.

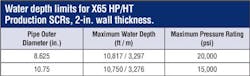

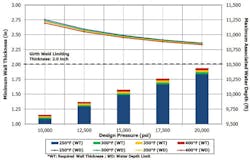

To give an idea of the water depths, pressures, and temperatures that current pipe and welding technology can provide, the minimum wall thicknesses for two production risers are determined. The wall thickness sizing is carried out in accordance with API RP 1111. The methodology includes checks of collapse, burst, and axial capacity. For high-pressure production risers, burst resistance predominantly determines the wall thickness. The API code allows for a relaxation of conservatisms if a burst testing campaign is conducted during manufacture.

The following ranges of design conditions are considered:

- Temperature range: 250°F - 400°F (121°C - 204°C)

- Shut-in pressures at surface: 10ksi - 20ksi

- Water depth: 5,000 ft - 10,000 ft (1,524 m - 3,048 m)

- Pipe outer diameter: 8.675-in., 10.75-in.

- Riser top angle: 12°

- 2.5-in. thick insulation

- 3 mm corrosion allowance

- X65 pipe grade.

The chart shows maximum wall thicknesses production risers with the associated maximum water depths for each wall thickness. The maximum water depth that the risers can be installed in is limited by the axial capacity of the pipe. Assuming a 2-in. wall thickness, the maximum water depths are given in the table. HP/HT SCRs can reach water depths of 8,000 ft (2,438 m) using X65 steel, with pressures up to 20,000 psi for the 8-in. riser.

To reach greater depths, higher strength steels are required, which introduces challenges in meeting welding mechanical properties or using alternative riser designs. Steel lazy wave risers (SLWR) are one option to go deeper by adding buoyancy and thus alleviating some of the weight the upper riser must carry.

Systems considerations must be taken into account for HP/HT SCRs. Installation loads will be higher than for lower-pressure SCRs, but a recent survey of J-lay vessels shows the installation loads are within current capacities of a handful of vessels. Flexible joint technology of HP/HT is currently still in development, so, on recent projects, operators have been choosing to design in steel or titanium tapered stress joints at the SCR hang-off. Due to the heavy wall riser pipe, these stress joints will see large axial loads and bending moments; for ultra-deep applications, this could result in very large forged taper joints requiring careful manufacturing procedures to ensure acceptable through wall mechanical properties.

Lastly, host vessels will have to be designed with sufficient capacity to handle the increased interface loads. With diligent engineering, none of these systems considerations prevent HP/HT SCRs from being successfully implemented.

For HP/HT wells, riser designs are reaching the limit of pipe manufacturing and weld fabrication; however, acceptable systems designs can be achieved and qualified by balancing the riser outer diameter and system configuration (simple catenary versus lazy wave) for the design pressure, temperature, and water depth combination.