Funmilola Asa

Rotimi Olajide-Adetolu

Ibrahim Orehin

Chevron Nigeria Ltd.

Offshore hook-up and commissioning activities on the Chevron-operated Meren Gas Gathering and Compression Platform (GGCP) project were completed offshore Nigeria during a tight, four-month window to deliver first gas from the 120-MMcf/d-capacity facility. The Systems Completion (SC) procedure was a key contributor toward the seamless commissioning of the platform during this short window. First gas from the facility was recorded on June 28, 2015.

Project profile

The Meren GGCP, operated by the Chevron Nigeria Ltd./Nigerian National Petroleum Corp. JV, was installed in late December 2014 at the Meren field offshore Escravos, Nigeria, in approximately 50 ft of water. The platform is part of the JV’s Escravos Gas Project Phase 3 Stage 2 to end routine gas flaring in Chevron Nigeria’s North Offshore Operational Area.

Dynamic positioning float-over installation of the integrated topsides onto the jacket substructure followed by the installation of ancillaries such as connecting bridges to existing production platform and emergency flare towers were completed on Jan. 1, 2015. The topsides, weighing about 7,000 tons, were fabricated and assembled in Ulsan, Korea. The jacket, piles, and ancillaries, weighing almost 3,000 tons combined, were fabricated in Nigeria under an EPCI contract with Hyundai Heavy Industries (HHI). The platform gathers associated gas from about nine production platforms and compresses the gas prior to transporting through a 20-in. pipeline to an onshore gas processing plant. The key components of the Meren GGCP, include: two 50% gas compression trains, two 100% turbine generator sets, one essential power generation package rated at 650-kW, one platform crane, and a flare system designed to handle emergency flare from the platform and the connected production platform which has capacity to handle 170 MMcf/d.

Systems completion procedure

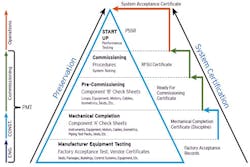

The SC process is the sequential activities within a project to verify and prove that the selection, design, construction, installation, integration, testing, and preparation of systems have been completed correctly; confirming the facility is ready for start-up and operations. It is the structured process through which the technical integrity of a newly built or modified facility is verified, and then it is turned over from the project team to base business owners (operations, maintenance, and facilities engineering). Industry-wide application of the SC process is guided by API Recommended Practice 1FSC, while Chevron’s Project Resource Co. also provides company-specific guidelines through the Systems Completion Handbook supported by a suite of procedures and detailed guidelines.

The SC process begins early in a project and continues throughout the construction phase. Appropriate documentation and certification is used to facilitate the effective custody transfer of the facility to the base business. Key activities include manufacturing equipment testing, mechanical completion, pre-commissioning, commissioning, and ready for start-up. The lead roles for SC are rotated among the construction, systems completions, and operations teams for each of these activities. The SC team takes the lead for pre-commissioning and commissioning activities while supporting operations and construction for the other activities.

Systemization, a critical step in SC, is the process of breaking down a facility into manageable and commissionable pieces to optimize the phased handover and start-ups. A suite of tools and documentation support the SC of a project. These include milestone certification (mechanical completion, ready for commissioning, ready for start-up, system acceptance, and facility acceptance), asset registers, inspection test records/check sheets, system/sub-system turnover strategies, plans, procedures, etc. A key tool for effective SC deployment on any project is the use of a database for planning, tracking, and progress reporting. The database tracks project activities to ensure that the facility is constructed, commissioned, and ready for safe operation while providing a comprehensive set of data for use during the life of the asset. Hence, the effective deployment of SC has far reaching benefits in the successful operating life of the facility while ensuring process safety compliance.

Best practices

System engineering was carried out on the Meren GGCP project with the facility subdivided into 27 systems and 165 subsystems. The system boundary definitions considered the sub-contractor scope delineations, which supported the successful integration.

The SC process on the project helped to manage the interface, integrate stakeholder involvement, Quality Assurance vs. Quality Control (QA/QC), and information management compliance into construction and commissioning execution. A key example is, while developing the launch files for the SC database during detailed engineering, a detailed cross-referencing of tagged equipment across discipline documentation such as process and instrumentation diagrams and electrical diagrams helped to resolve interface issues between disciplines and identify missing items. In addition, an SC turnover strategy workshop held early in execution defined the system acceptance criteria that would align with the base business operations. A key recommendation is to develop system acceptance criteria check sheets to facilitate sign-off by operations and track progress with the SC database.

The database software used on the Meren GGCP project served as a secure repository of the project construction and QA/QC documentation. Updates to engineering deliverables/launch files were tracked with database change controls, which provided qualitative analysis of changes for use in verifying contractor claims. This helped to identify changes that were a result of a lack of engineering due diligence by the EPCI contractor and those that were a result of a company request. Another feature used on the project is the allocator application within the SC software, which ensured the filing of check sheets based on a bar code scanning system. This facilitated the check-out and check-in of documents for proper tracking and it also provided an electronic backup for the contractor’s hard copy check sheets thereby securing the key process safety information.

This system-based progress tracking identified bottlenecks and helped prioritize and focus completion efforts toward systems that were close to being ready for pre-commissioning/commissioning. Weekly progress meetings were held with the contractor to guide work planning and drive early closure of potential commissioning issues during construction. The contractor also incorporated SC processes in their commissioning execution plan and QC procedures.

The SC process also links completion certificates/milestones to key activities and punch list close-out. This was critical to ensuring that the contractor closed out critical punch list items as defined by the completion certificate requirements thereby resulting in a high-level of fabrication yard completion and a significant reduction in carryover works on the GGCP topsides; thus, facilitating smooth commissioning offshore. For instance, a mechanical completion certificate is linked to the completion of construction inspection test records (A- check sheets) and the closure of safety related punch list items. Multidisciplinary walk-downs were conducted to verify the readiness of systems for construction completion and ready for commissioning stages. This resulted in the generation of punch list items with the critical ones required to be closed as appropriate prior to certification. On the Meren GGCP project, the punch list items were managed through the database with fault codes (based on pre-determined categorization) that could only be changed/downgraded by the commissioning manager. Hence, the contractor was driven to complete the required punch list items in order to attain the necessary completion certificates for the systems as this was tied to milestone payments. The result was a reduction in punch list items at facility start-up.

Effective preservation was another key benefit of the proper implementation of the SC process. Early in the project execution, operations and maintenance (O&M) personnel reviewed vendor provided data and O&M manuals, and based on experience developed a checklist of preservation activities for all tagged equipment. This information was translated into the preservation tag-type matrix and tracked using the SC software though weekly preservation reports. The activities were categorized into phases: 1P - during warehouse storage; 2P - when installed at the fabrication yard; 3P - during sail-away and transportation; and 4P - after pre-commissioning.

Conclusion

The SC process is an integral part of successful project execution. It should be deployed early in the project as it provides a structured approach to project construction and QA/QC to ensure a seamless commissioning and facilities turnover to base business operations. The deployment of this process on the Meren GGCP project in addition to other robust project management and construction management practices were significant contributors to the success of the project commissioning and start-up. Another key enabler was the significant front-end loading, engagement, and alignment of key success drivers.

Consistent deployment of SC results in higher quality, improved schedule performance, safer start-ups, safer operations, improved reliability, and ultimately increased revenue.

Acknowledgment

This article is based on a paper presented at the Offshore West Africa Conference & Exhibition held in Lagos, Nigeria, Jan. 26-28, 2016.