VAALCO acts on failed ESPs

Electrical submersible pump (ESP) failures at its Avouma 2-H well continue to plague VAALCO Energy. The company recently pointed to the equipment as the main reason that its production offshore Gabon declined during 3Q.

The operator is mobilizing a hydraulic workover unit onto the Avouma platform to remove the ESPs so that the manufacturer can analyze the cause of the failure. VAALCO is working on a plan to replace the pumps in the affected wells and anticipates restoring at least part of the shut-in production by year-end.

It estimates its net share of the cost at around $3.1 million.

In late August, days after upping its stake in the Etame Marin permit by 3.23%, VAALCO restarted production on the Avouma platform after a July failure of the primary ESP on Avouma 2-H. It said then that performance was stable, with the well producing approximately 1,850 gross b/d of oil. The well was producing around 2,700 gross b/d of oil prior to the first ESP failure.

Prior to attempting to start the secondary ESP, VAALCO and the original equipment manufacturer which installed the pump worked closely to re-design the start-up procedure and adjust the operating conditions in an effort to prevent another failure.

This summer, the electrical submersible pumps (ESPs) in the South Tchibala 2-H well failed, too. The well, which had been producing 1,700 b/d of oil through the Avouma platform, was shut-in.

After its August re-start, the lower pump in Avouma 2-H remained operational for approximately 10 days. In mid-September, VAALCO informed that it had attempted to restart the lower ESP without success and the well was temporarily shut-in pending a workover. The company also announced it had been forced to shut in the well once again and had begun the process of mobilizing a hydraulic workover unit to the platform to recover failed ESPs in the Avouma 2-H and South Tchibala 2-H wells.

In September, the company said it planned to immediately install a replacement ESP in the Avouma 2-H well and said then that it anticipated restoring production from the well by mid-4Q.

ROVs adapted for Shell inspections

James Fisher Subsea (JF Subsea) claims to have reduced inspection downtime for Shell UK through use of asset-based remotely operated vehicles (ABROV) on inspection programs in the North Sea.

To avoid the hazards of securing an ROV to the offshore platform, JF Subsea provided Shell UK with a gravity-based ABROV system. The units were trialed on a planned riser and structural inspection on the Brent Bravo platform in the UK northern North Sea. Post-project analysis concluded that downtime was reduced to 2% over the four-month campaign.

Following the 2016 ABROV inspections on the Brent Bravo, Shearwater, Curlew, Brent Alpha, Gannet, and Nelson platforms, Shell UK is now in discussions with the contractor on supplying this service for the next five years on various North Sea platforms.

Subsea 7 expands Egyptian backlog

Subsea 7 has completed offshore operations on the fasttrack East Nile Delta project in the Egyptian sector of the Mediterranean Sea.

During 3Q, theSeven Borealis was engaged in pipelay for the first phase of the West Nile Delta project.

Last month, Subsea 7 secured an EPIC contract for the Atoll project in the same area, lifting the total value of its contract awards offshore Egypt over the past 18 months to almost $1.8 billion.

Elsewhere, the company completed its third seasonal campaign on Statoil’s Aasta Hansteen in the Norwegian Sea. All flowlines and control cables are connected, and the subsea infrastructure is now ready to hook up to the spar platform when it arrives in 2018.

In the UK central North Sea, work on Premier’s Catcher project neared completion with installation of a technically complex riser system comprising 10 flexible risers and three umbilicals supported by three large tethered mid-water arches.

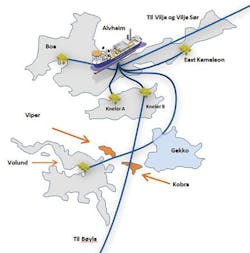

Tieback enables Viper-Kobra start-up

Aker BP has started production from the Viper-Kobra structures via a subsea tieback to theAlvheim FPSO in the Norwegian North Sea. Development costs came in on budget at around $217 million, and included drilling of two wells, subsea installations, pipelines, and hook-up. The initial production rate should average 15,000 boe/d.

The two small developments are in the Alvheim area. Kobra was discovered in 1997 in production license 203, and Viper was discovered in 2009 in PL 203 in 2009. Those accumulations constitute part of the Alvheim field and development was therefore included in its plan for development and operation.

The operator originally announced that the development would be given the greenlight in January 2015. The scope comprised a new subsea installation with a pipeline tied into the Volund manifold. The four well slots accommodate one well each on Viper and Kobra, with two slots remaining for potential future wells in the area.

Aker BP estimates that the two reservoirs each contain about 4 MMbbl of recoverable oil including gas. The total recoverable is 9 MMboe.

Aker BP operates the Alvheim license in partnership with ConocoPhillips and Lundin Norway.