Odd-Magne Nesvåg

Aleks Karlsen

Stian Ruud

DNV GL

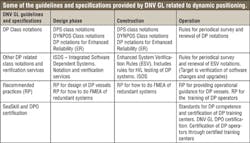

Dynamic positioning (DP) is a system that automatically keeps a vessel on a given position and heading by using the vessel thrusters and propellers. Today such systems are extremely accurate and applied by a wide range ofvessels due to their many advantages. Examples of operations performed with DP include offshore supply and construction, drilling, lifting, pipe and cable laying, diving, and many more. Applications also include vessels with larger capabilities used in deepwater and harsh environments.

Risks

The main risk in DP operations is loss of position control and subsequent injury to the DP vessel or nearby objects, with potential loss of lives, damage to installations, and emissions to the environment. For the maritime and offshore industry, this introduces increased risk and potential larger consequences related to their DP operations. These risks need to be handled and managed. At the same time the industry faces increased expectations from authorities and the public for reduced environmental emissions and incident-free operations.

DP class notations

DP vessels classes range from DP-0 to DP-3. DP-3 implies the highest integrity toward loss of position and is typically used in operations with the highest risk potential. Today the most commonly used DP classes are DP-2 and DP-3 which requires redundancy in technical design so that the vessel can safely terminate an operation if a system fails. For DP-3 the systems belonging to different redundancy groups shall be physically separated to withstand the consequences of fire or flooding.

Advanced technologies

In the design of modern DP vessels, advanced technologies are being introduced to produce more flexible designs that are able to carry out efficient and environmentally friendly operations. A recent example of this is the maritime and offshore industry's use of advanced software-based protection systems to run DP with redundant power systems that are closer connected (closed bus-ties). Another trend is increased use of software to integrate more functions into larger software-dependent systems. At the same time, the challenge is to ensure that DP vessels and operations comply with acceptable safety standards. One result is the increased need to control the risks involved in all phases of a DP unit's life cycle. The main phases in this aspect can be divided into design, construction, and operation.

Design phase

It is crucial that the design is based on a documented philosophy which considers both DP capabilities and the unit's capabilities to perform its industrial mission. The DP redundancy design intentions must be clearly specified with respect to grouping of equipment and capacity. This also includes specification of the intended capacity after a failure in the DP system.

The industrial mission capability is the unit's capability to perform its intended operation (e.g., drilling). For the industrial mission systems, it is important that the power system, which is normally shared with the DP system, be designed with sufficient capability for all intended operational modes. The power system must be able to support both systems simultaneously.

Failure to meet such design requirements may impose increased risk during operations or increase the possibility that the vessel is not able to perform its industrial mission with the intended capabilities.

Construction phase

Typically a high number of equipment suppliers are involved in building a vessel. This imposes a huge coordination challenge and implies a need for a system integrator to control the integration of the systems during the construction phase. Lack of sufficient control imposes a risk that problems will not be discovered. Problems found late in the project can cause significant delays in delivery plus extra costs. The construction phase must also include thorough testing to verify the required robustness and fault tolerance. Typical test methods today include failure mode and effect analysis (FMEA testing) and simulator testing using hardware in the loop (HIL) simulators.

Operational phase

The achieved quality at delivery influences the operational performance and the risk for incidents, accidents, and potential downtime during the vessel's operation. The main technical factors influencing the operational risks are typically related to wear and tear, conversions, maintenance, and replacement of software and hardware. To control these risks, the main mitigation will be a rigid change management system combined with verification through documentation, analysis, and testing. The management of crew and operators' competencies is also crucial to maintaining acceptable risk levels and the main mitigation in this respect is education and training.