Advances in dual gradient drilling will facilitate deepwater development

Don Francis

Special Correspondent

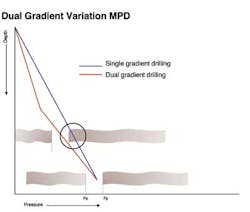

When drilling conventionally, the column of wellbore annulus returns (mud and cuttings) presents a single depth versus pressure gradient. Dual gradient drilling (DGD) technology involves creating two or more depths versus pressure gradients in the returns path.

The concept itself dates to the 1960s, and during the 1990s the technique gained favor as an underbalanced drilling (UBD) technique on land drilling programs. A parasite string alongside the casing enabled the injection of a gas (usually nitrogen) at some depth, creating a DG. The objective was to invite the well to flow while drilling, primarily for the purpose of increasing well productivity by avoiding damage to the porosity of the pay zone.

The technique was later introduced tooffshore drilling as one of the four variations of managed pressure drilling (MPD). Unlike onshore UBD applications, the offshore application of DG is certainly not to invite the well to flow. The primary purpose is to more precisely stay within shifting, narrow and sometimes relatively unknown safe mud weight windows, and to achieve greater depths with each size casing string.

Don Hannegan, Weatherford manager, strategic technology development-MPD notes that in conventional deepwater and ultra-deepwater operations, the marine riser is filled with weighted mud and cuttings that exert excessive hydrostatic pressure on the exposed wellbore. This severely impacts casing design and creates a host of problems, not the least of which is well control. DGD is particularly suitable for addressing a number of offshore drilling challenges because it enables a wellbore pressure profile to more closely match the pressures presented by nature, reducing or eliminating the impact of water depth on well design. Regarding well control, current methods of achieving dual gradient enable drilling with heavier mud weights than is possible with conventional methods. Because dual gradient is created in the annulus returns path and not within the drill string, concurrent processes such as MWD and LWD are usually not affected.

The method with the greatest number of applications to date is riserless dual gradient, also called riserless mud recovery. This method employs subsea pumps and a dedicated flowline for returning mud and cuttings back to the rig, as opposed to the riserless "pumping and dumping" method of establishing subsea wellheads.

There are several DGD methods suitable for deepwater rigs with conventional marine risers and subsea BOPs:

- Subsea mud-lift (pumps near the seafloor)

- Controlled annular mud level (pumps shallower to the rig)

- Mud dilution (with concentric riser)

- Inert gas injection (with parasite string).

Wellbore pressure management (ECD management) is similar to the constant bottomhole pressure (CBHP) variation of MPD. Depending on the method and specialized equipment, modified kick circulation procedures may be required.

The subsea mud-lift method uses positive displacement pumps and is often referred to as "true" DGD because the subsea wellhead sees only seawater gradient pressure, as if the rig were on the seafloor. Depending upon water depth and capability of the subsea pumps, the method may allow drilling with a kill-weight mud, posing less risk of environmental consequences in the event of an emergency disconnect.

The controlled mud-level method is often referred to as "mid-riser DGD." The level in the riser some distance below sea level is managed by subsea pumps mounted alongside the riser.

The mud dilution method is somewhat akin to that of using a booster pump to inject cuttings-free mud into the riser at some depth. A concentric riser enables a lighter mud from the rig to be injected between the inner and outer riser into the annulus returns. Centrifuges may be used to recondition the injectable mud.

The inert gas injection method involves injecting an inert gas, such as nitrogen, into the riser or casing at some depth. The use of a nitrogen production unit (membranes) aboard may be most practical source.

In each method, the specialized equipment required should comply with applicable industry standards. For example, the subsea mud-lift method requires a subsea rotating control device (SRD) to serve as an annulus barrier, allowing the riser above to be filled with seawater and to positively divert returns to the subsea pumps.

It is important to note that each method requires considerable preplanning, appropriate hazard identification, hydraulic flow modeling, crew training, and (in most waters) pre-approval by regulatory bodies. The specialized equipment required to perform each method is still relatively new, and care should be taken to qualify each component of the DGD "kit" with shop tests or controlled field trials to ensure that it is fit for purpose.

Dual gradient drilling challenges

According to Frederic Jacquemin, Pacific Drilling's dual gradient drilling program director, there are several challenges to successful DGD operations. "There is a lot of equipment involved, a lot of heavy equipment especially on the particular dual gradient drilling technology that we are deploying with Chevron," said Jacquemin. "Most of the equipment is right above the BOP on the seabed. The key equipment is called the MaxLift Pump. It's about the size and the weight of the BOP and has the complexity of the BOP as well, with control systems and hydraulics, and despite all the redundancy built in the system presents some incremental overall downtime risks."

The MLP is the heart of the DGD system, says Jacquemin. "It's the pump that is on the seabed and brings all the returns on a separate 6-in. line along the riser to provide the dual gradient mechanism. Therefore, we end up with heavy mud below the mudline and a very light fluid with a density equivalent to seawater inside the riser, above the pump."

In deepwater, mud-lift pumping is the solution that provides the most benefit of dual gradient, "because we have the benefit of the full mud column all the way down to the seabed being lightened to the equivalent seawater density," Jacquemin explained. "The full benefit of dual gradient can only be achieved with the pump right on the seabed; any other mechanism of pumping somewhere in the mud column or in a dilution-based system cannot achieve those results."

Another challenge, he notes, is the automation of the control systems for these pumps. "We've spent a lot of time getting our rigs ready for dual gradient drilling by automating a lot of the fluid managing system. We are talking about three different types of fluid: the heavy mud that is used to drill below the mudline, the riser fluid that is equivalent to seawater, and then we have the seawater power fluid that is powering this pump on the seabed," Jacquemin noted. "So we are talking about three completely independent fluid systems that need to be managed, that need to be transferred from A to B to be manipulated on the surface without any mixing of the different fluids."

And, it should be very clear at all times where each fluid is and how it has been transferred, Jacquemin added. "Having all those additional lines, additional valves properly tagged, most of them being remotely controlled, all the virtualization tools and screens and means to operate those valves and educate all the crews and the third parties into the different lineups is where we spend a lot of effort, and this is where the bulk of the rig modifications were, to revamp the fluid management system."

The technologies that need development are in the valve control systems and in data transmission, Jacquemin observes. The goal is "to gain as much as we can in rig integration, in having the controls of the system from the rig side and from the pump side all integrated into a comprehensive system on the rig. This will assist with training of personnel, and the virtualization of different lineups will make sure that everything is lined up properly and minimize the risk of misplaced fluid, environmental contamination, or other incidents by having the wrong lineups."

Ultra-deepwater DGD

GE Oil & Gas is one of the companies leading the way in the development of new dual gradient drilling technology. Ahmet Duman, GE Oil & Gas MaxLift pump engineering manager, recently described some of his company's latest efforts in this arena. "Our DGD technology removes the unwanted hydraulic pressure on a formation by filling the riser with seawater-density fluid instead of mud, and using a subsea pump at the mudline to transfer mud from wellbore annulus to the rig through a separate mud return line," explained Duman. "The hydrostatic head of the mud from the rig to mudline is totally eliminated from acting on the formation, replaced with the hydrostatic head of seawater-density fluid. The system can drill in tighter fracture and pore pressure gradients of heavy subsalt plays, making previously unreachable reservoirs possible to reach."

"Our dual-gradient technology was developed and tested 13 years ago in a joint industry project and proven in the world's first DGD well in 2001 in theGulf of Mexico," Duman continued. "After a seven-year pause, we spent more than four years designing and manufacturing the subsea MaxLift Pump, which is the heart of the entire system. The 30-ft high pump, the size of a lower blowout preventer stack, is powered by seawater and lifts mud to the surface from the seabed floor. It is rated for 10,000 ft water depth and can pump up to 1,800 gal/min, at up to 6,600 psi."

DGD becomes essential

"Appropriate caution is advised, but it is well worth the effort and cost because the size of the prize is great," Hannegan observes. "We have already drilled almost all of the easy deepwater prospects with conventional systems, whose hydraulic principles were developed more than a century ago. Remaining prospects are likely to be considerably more challenging or even impossible to drill safely and effectively with conventional means." As with other variations of MPD, DGD's ability to drill the undrillable is likely to ultimately play out to be its legacy—that of increasing the world's recoverable resources from what otherwise would have been the case.