New pipe-in-pipe design ensures effective insulation

Derek Bish

Tata Steel

Increasing demand for energy, matched with high commodity prices and advances in technology, are driving operators to extract whatever reserves remain in the challenging UK continental shelf. Therefore, the requirement to transfer these multi-phase products from often high-pressure/high-temperature (HP/HT) wells back onshore is an even more demanding prospect.

Up until now, the common belief in the industry was that pipe-in-pipe systems able to withstand environmental challenges such as corrosion, structural integrity, and thermal management, would be too costly and complex to apply to riser systems.

Tata Steel worked closely with supply partners to engineer, procure, and construct these assemblies to further develop this innovative technology as a cost-effective solution to flow assurance issues.

Need for insulation

HP/HT fields are technically more complex to develop because of the inherently higher energy in the well fluid and its multi-phase composition. Managing the extreme pressure and operating temperature must be based and evaluated on criteria such as corrosion, maintaining structural integrity, and thermal management.

One particular challenge is the management of pipeline shutdown. Less expensive solutions for managing the insulation of bends such as wet coatings, compromise overall shutdown times due to reduced thermal efficiency. Solutions, such as "self-draining" spools, present a significant design challenge that can be mitigated by the inclusion of pipe-in-pipe bends, enabling the same thermal integrity to be maintained in the whole line.

Tata Steel has previously implemented a solution for pipe-in-pipe bends for a North Sea development. Since then, new insulation techniques have been developed that give far superior insulation properties.

Risers, spools, and bends

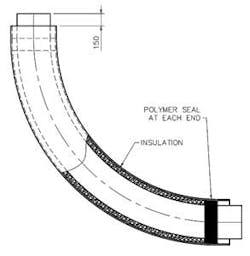

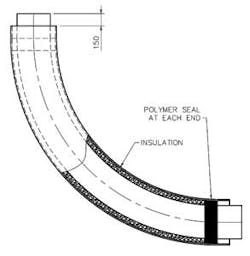

The main challenge with the construction of pipe-in-pipe bends is how to pass the inner flowline bend into the outer casing pipe. It is important that pipe bends have a straight portion on the end to enable efficient welding to the next pipe section and this can present the insertion of one bend into the other.

The second construction challenge is efficient insulation. Wrapping or sheathing is simply not practical here as the insulation would occupy the annulus of the assembly and prevent the integration.

New insulation system

The system developed by Tata Steel overcomes these problems by deploying granular Nanogel insulation into the annulus of the pipe-in-pipe system. Nanogel is made by first forming a silica gel, then expelling the water from the silica matrix. The resulting material is granular with trapped nanopores of air, inhibiting heat transfer by conduction, convection, and radiation (with the inclusion of an opacifier).

The deployment of a novel polymeric bulkhead, cast directly into the annulus, provides a solid barrier to retain the insulation, which allows for the relative movement of the inner and outer bends. The polymer is a "syntactic" material, silicone rubber with glass microspheres dispersed through the matrix with high strength, flexibility, and thermal efficiency. The tangent ends of the inner and outer bends are held rigidly to ensure that the assembly tolerances achieved at manufacture are retained when the unit is transferred to the welding contractor for incorporation into the pipeline spool or riser.

In order for the insulation to be effectively deployed and provide the consistent thermal performance, the annular gap throughout the assembly must be uniform. It is important the manufacturing tolerances of the pipe and bends are closely controlled.

Steel pipe and bend manufacture

Together with Tata Steel, Eisenbau Krämer (EBK) and the pipe bending plant of Salzgitter Mannesmann Grobblech (SMGB) have developed a series of controls, including a process and measurement system, to ensure all bend dimensions are closely controlled and mating bends can be produced, matched, and paired to ensure the most accurate assembly is produced.

In respect to the process-related thinning in the extrados of the hot induction bends, the wall thickness for the inner and outer mother pipes was increased accordingly. To match precisely, the mother pipes have been manufactured with the same ID as the riser pipes.

EBK supplied Tata Steel with the mother pipe, which has material properties that allow formation through hot induction bending. The main material challenges are to ensure the mechanical properties are suitable after bending. Therefore, SMGB is taking responsibility for the chemical design of the pre-material. This also involves the consideration of a series of heat treatment and forming processes. EBK uses a multi-pass welding process and steel plate from premium mills in Europe. The manufacturing process at EBK generates pipe of the closest dimensional control through a series of cold forming and sizing operations such as external calibration.

At the SMGB pipe bending plant, the special mother pipes are bent by hot induction bending. Heat is applied through electrical induction to the mother pipe materials and the pipe is slowly formed to give the correct geometry. In most pipeline applications the critical dimensions are the positions and attitudes of the ends of the bends (center-to-end dimension) to maintain the overall geometry of the pipeline. However, with pipe-in-pipe bends it is important that the bend radius is also accurately controlled to ensure the two bends can be integrated. The precise dimensions after bending also need to be maintained following heat treatment. For the inner clad bends, a full-body quench and temper heat treatment is applied at the SMGB bending mill in order to guarantee homogenized material properties for the bends, to fulfill mechanical and corrosion requirements.

HP/HT material properties

Additional material complexities have to be overcome. Generally, in HP/HT lines there are challenges because of corrosion, low temperature toughness, and strength. These parameters require careful material selection to maintain the balance of properties from the outset through to bend production. Thermal stresses need to be managed as the loads are shared between inner and outer pipe. In addition, the insulation can lead to extremes of temperature being retained in the pipe materials during operation and shutdown that can form challenging conditions for conventional steel products.

Conclusion

HP/HT well environments present some of the most challenging and technologically demanding conditions for field developments, not least because the properties in each reserve offer significant challenges in terms of material selection and design.

Tata Steel and its supply partners have expanded capabilities further with the design and creation of cost-effective insulated pipe-in-pipe bends for risers and spools - an accomplishment previously considered too difficult.

Pipe-in-pipe bends, while challenging technologically, can lead to simplification of overall pipeline design and can give better pipeline performance in times of operation and shutdown.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com