Evolution of subsea well system technology

Preston Mason, Subsea Consultant; Granherne/KBR

Industry develops production technology to follow where the explorer leads. In its methodical manner, the oil industry moved from land operations to inland waterways and then to offshore, with surface-piercing platforms in increasing water depths. As water depths of interest began to exceed proven fixed-platform technology, or as development costs increased to the point where reserves became uneconomic, the industry started developing subsea well technology as the possible key to deeper water.

Although a few subsea wells were installed earlier, subsea well technology development really started in the late ’50s. The deepest fixed platform was in about 300 ft, and the deepest floating drilling was in 640-ft water depth. Explorers were developing theories, indicating the possibility of prolific oil and gas reservoirs in deeper water.

By the ’90s, technology matured to the point that installation times and risks had fallen, start-up times had been significantly reduced, and operations were becoming considered normal. Installation times for multiwell system subsea equipment of less than two months, start-up times of less than two weeks, and availability during the first year operation of 99%, were becoming common.

This paper presents a “helicopter” view of developments in subsea technology, starting with the drivers and restrictions for early R&D, moving to the early development projects, describing the author’s selection of the most significant developments as the technology matured, and describing some recent application of the technology.

Subsea technology development timeline

It is worth understanding the environment in which subsea well technology was being developed. In 1960, the price of oil was $3/bbl and gas was $0.25/Mcf, and predicted to stay at those levels. The deepest fixed platforms were in 300 ft of water and the deepest floating drilling was in 600 ft. Actuated production valves were new. The only remote controls were simple hydraulic systems. There were no underwater flowline connectors, and there was no reliable, long-lived subsea electrical connector, much less underwater make and break connector. All equipment was guided to the seafloor on wires. Underwater cameras required a lot of light, and gave poor resolution. ROVs did not exist.

In that environment, oil company execs viewed subsea wells as the choice of last resort - used when economics or the environment precluded the use of “conventional technology.” Subsea equipment reliability was unproven, and the view was that “if you could not put your hand on it, you could not trust it.” Fear of equipment and well reliability drove the desire for low cost intervention capability, without regard for the type or quality of the reservoir and with little acknowledgment of research progress.

The period from the mid-’50s to the mid-’70s could be classified as the “concept select” period of subsea technology development. Oil companies independently defined and evaluated alternative ways to develop reserves in deepwater, selected the best, and developed those through component and prototype testing to a “commercial ready” status. Selection criteria included the required new technology, the cost and time required to “commercial ready”, the probability of success and the consequences of failure, and safety to people and the environment (yes even then).

Figure 1 provides an evolutionary timeline of subsea technology, and it shows that development of wet, remote-controlled satellite trees started in the mid-’50s with emphasis on proving actuated valves, simple hydraulic controls, and flowline connectors. Lack of proven reliable controls and monitoring equipment, and diverless maintenance procedures drove development of systems whereby subsea equipment was housed in dry chambers and crews could work at 1 atm pressure. One oil company pursued single well chambers and several companies developed dry manifold centers.

Development of all wet, diverless multiwell systems started in the early ’60s. Lack of accurate underwater measurement and positioning equipment drove use of well-manifold templates to control the position of subsea equipment for installation and maintenance. In the late ’70s, development of the ROV and the desire for flexibility in configuring subsea systems led to development of the “clustered” concept where satellite wells are drilled and connected by flowlines to a remote manifold. Component development has churned along from the early days and continues on to the present day. Some of these individual concepts are discussed in detail below.

Dry chamber systems

One of the first approaches to multiwell subsea production systems was to design chambers to house land trees and manifolds on the seafloor with no new development, and to allow oilfield production personnel to work on the equipment in a dry, 1 atm, “shirt sleeve” environment. Workers were expected to install flowline and controls connections, and to repair the production equipment. This approach was appealing to those in a hurry to develop in deepwater and did not want to wait for development of subsea connectors and other components.

Lockheed had experience with manned diving bells, and thus was contacted to develop a 1 atm chamber to house a conventional, above-water tree, and to develop a man transfer capsule to get people from the surface to the chamber. The company subsequently contracted to design a dry manifold chamber.

In operation, the well was drilled from a floating drilling rig using a “wet” wellhead, the downhole completion installed, and the well suspended. The chamber was lowered, landed on the wellhead, and locked. The man transfer capsule was lowered from the surface, landed on the “tea cup” at the top of the chamber, and sealed. Men in the upper chamber of the transfer capsule dewatered the transfer lock, and went into the well chamber to work. A wire-line lubricator was installed and tubing plugs pulled to complete the well. Flowlines and control umbilicals were pulled into the chamber and connected to the tree. The men left the chamber, and production was started by remote control.

Similarly, North American Rockwell had experience with small submarines and subsea habitats and was contracted to develop a dry manifold chamber to which wet trees could be connected. Men were to be transferred from the surface in a small submarine.

The dry chamber systems lost favor for several reasons, including realization that production equipment had to survive wet submergence in case the chambers flooded, that costs of dry chambers increased significantly beyond 1,500-ft water depths, and the inherent operational cost, time and concern of transporting men to the chambers and placing them in close proximity to “live” wells and other production equipment.

Wet satellite wells

Wet wells started with the use of the land trees underwater. This evolved by development of flanges that could be more easily installed by divers, and by development of remote controlled valves. The early remote controlled valves evolved from equipment developed for drilling BOP’s.

The size and cost of individual valves, and the realization that a stacked valve tree could not withstand horizontal forces that might occur during installation from a floating drilling rig, prompted the industry to move toward “block trees” where the valves are machined into a single forging.

The block concept was problematic at first, because of the need to accurately drill long, straight holes close together in a forging; many forgings were lost in manufacturing, and it was common for critical delivery to start with an extra forging. The technology developed to essentially eliminate this risk by the ’70s. Block trees are used widely now because of their reduced height and weight, and for deeper water and dynamically position installation vessels where their increased strength is important. Numerous versions of block trees currently are being used.

Some companies experienced failures with downhole safety valves and the need to frequently re-complete multi-zone wells. This led to the development of the “through-bore” tree. This was a vertically oriented tree with 7-in. master valves. The completion could be pulled through the tree bore without removing the tree. This tree had limited use because of the difficulty of designing and manufacturing the large bore master valves for higher pressures.

The horizontal tree followed the through-bore tree. The horizontal tree has no valves in the vertical bores of the tree. There are two valves in the valve block in each of the horizontal production and annulus flow paths between the well bores and the flowline connection. One valve in each flow path is designated the “master valve”, and the other the “wing valve”. There is a crossover between the annulus and production string to allow for bleeding annulus pressure.

The operational difference between a conventional “vertical” tree and the “horizontal” tree is in installation. With the vertical tree, the well is drilled and the completion is run through the drilling riser and BOP. The well is suspended, usually by setting plugs in the bores of the tubing hanger, but sometimes also downhole. The BOP and riser are then pulled or “set aside”, and the tree is run on pipe, a completion riser, or a running string. With the horizontal tree, the well is drilled and suspended. The tree is run and the well completed. A special “test tree” normally is used above the tubing hanger to allow sealing the tree bores and using the BOP during the completion operation. The drilling riser and BOP are used to run the tree and set plugs in the bores during completion. The tree cap is then run.

The modern vertical tree and the horizontal tree are used in most projects today, and arguments rage about which is preferable. The author’s view is that the selection should be project specific. If the project is fast track so trees are on the critical path of drilling the wells and starting production, and the reservoir can be managed with hydraulic sliding sleeves (hydraulic smart wells), the vertical tree is the answer. If drilling is not on the critical path of project schedule, and it is known that the well will require service or change of the completion during the first few years of operation, horizontal trees are the answer.

Conventional diver or remote vehicle equipment

Service companies interested in developing the early underwater intervention systems had the same dilemma as production system developers, namely, to determine whether men were required subsea.

One of the first units developed to observe subsea installation and operation, and to perform work tasks on “conventional” subsea equipment designed for diver intervention, was the “ARMS” diving bell, developed by Oceaneering. This bell was equipped with lights, cameras and two manipulator arms. In operation, ARMS was lowered to the seafloor, was driven by the operators to the work site using the built on propulsion thrusters, grabbed support points on the subsea equipment and performed the work.

Diving suits were developed next for those who believed divers were the only reliable maintenance system. The WASP, shown in Figure 2, was a second-generation suit developed in recognition that early suits moved slowly on the seafloor and that the man was subject to tripping or falling. In this unit, the operator’s legs are together in a cocoon-shaped chamber and the unit uses propulsion to move rather than the operator having to walk. The swimming WASP has much greater freedom to maneuver and the risk of entanglement is reduced.

Photo courtesy of Oceaneering.

The Cable and Umbilical Retrieval Vehicle (CURV) was one of the first attempts to develop an underwater work vehicle remotely controlled from the surface. It also was among the first of what would become known as remote operated vehicles, or ROVs. This vehicle was equipped with electrohydraulic controls and propulsion, TV and lights, and two manipulator arms - one for grabbing and the other for performing work. In operation, it was launched from its mother ship, lowered on an umbilical, “flown” by an operator on the surface to the work site by remote control, where it grabbed onto the subsea structure and performed work. It did not have gyroscopic positioning and communication was crude. This unit could do only simple tasks.

Photo courtesy of Oceaneering.

Today, ROVs are available readily in most areas with 200 to 300 hp, gyroscopic guidance systems, and superb communication systems. Available ROVs with special tools can perform work in installing, troubleshooting and in operations/maintenance of subsea equipment in water depths to 15,000 ft. The precision and intricacy of work that can be done with a modern ROV was unimaginable a few years ago.

All wet, diverless multiwell manifolded systems

The first system was developed in the GoM, with the first commercial use in the late ’70s in the North Sea. The significance of this was total commitment to development of controls, sensors, flowlines, and underwater make and break hydraulic and electric connectors; and the maintenance procedures to replace them.

In the first system, wells were drilled through a template that supported a manifold in the center. This approach allowed subsea equipment to be installed on guidelines and fixed the relative position of the equipment, eliminating need for accurate subsea measurement or navigation. The maintenance system was manipulators transported on a vehicle that landed and moved on a track around the manifold, avoiding the possibility of collision with subsea equipment.

As subsea measurement and navigation became proven, use of the template structure became unnecessary. Development of the ROV eliminated the need for tracked maintenance vehicles. Production components developed in this program were the basis of today’s wet systems.

Clustered well developments

When improved subsea measurement and navigation/communication was proven, and the need for templates was eliminated, the “clustered” well system first used with dry chamber systems was revived in all-wet configuration. All-wet clustered well systems started in shallow water in the North Sea in the late ’70s. This was the point where flowline connections and subsea controls and umbilical connections were deemed commercially ready. These systems were installed with diver assistance. Diverless clustered well systems started commercial application in Norway, Brazil, and the US GoM in the mid-’80s after diverless flowline and connection systems, and ROV replaceable control modules were deemed commercially ready.

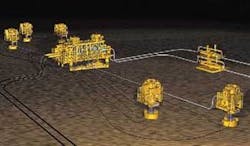

Clustered wells are now the concept of choice because of inherent flexibility. The clustered approach allows:

- Location of the wells to best develop the reservoir

- Scheduling well drilling and other construction activities to accommodate equipment and installation vessel availability, and to meet production needs and investment plans

- Future expandability with minimal up-front investment.

In most areas, these advantages outweigh the obvious disadvantage of increased vulnerability to dragged objects.

Subsea control systems

Development of components such as valves, chokes, controls components, seals, and connectors started as soon as a need was identified in one of the system concepts under development. The criticality of the component to a system concept or to a manufacturer’s or contractor’s envisioned product line controlled the timing of individual component development. This work started in the mid-’60s and continues today.

Development of remote controls started with hydraulic controls - “direct” with one control line per tree function, then “sequenced” where one or multiple functions were controlled through one hydraulic control line. These first hydraulic systems used water-based fluids developed for drilling BOP controls. The BOP fluids were corrosive, and either gelled or precipitated solids when left stagnant in a control umbilical or valve actuator for long periods.

Development of electrohydraulic control systems started in the ’50s using US Navy subsea connectors - which turned out to be unreliable for underwater make and break. Serious development of the subsea electrohydraulic system started when Exxon contracted TRW Systems to develop a reliable system, and started working with hydropower and connector manufacturers to develop reliable hydraulic and electric connectors. Modern systems are based on the work done in the Exxon system.

Subsea and downhole pressure and temperature sensors, and multiphase meters have been available for some time. Downhole sensors installed in the ’70s were prone to “drift” in calibration with time, the original electric cables were difficult to install with the tubing without damage, and the wellhead feedthrough connectors were unreliable. Advances in transducer and conductive connector technology provided more reliable sensors. Modern downhole gauges can function for several years after installation. The multiphase flow meters can measure wet gas or multiphase liquids accurately enough for allocation of production between wells, and with accuracy that is better than has been used in the past for custody transfer.

Umbilicals

Steel tube multi-line umbilicals and multi-stab connections allow even the most complex control system to be implemented. The umbilical includes steel hydraulic fluid and chemical supply lines, electrical control and communications cables, and fiber optic communications cables. Manufacturers could not have supplied this umbilical reliably even five years ago.

The polymer hydraulic hoses used in early umbilical systems deteriorated in a relatively short time. Also, they were limited in collapse resistance. High Collapse Resistance, HCR, polymer hoses, reinforced with fibers, can operate with up to 1,400 psi higher pressure on the outside than the inside. Ability to reliably manufacture steel tubes, availability of HCR polymer tubes, and procedures allowing ROV installation of umbilicals has made connection of remote wells feasible. The “balanced” hydraulic connectors developed in the ’80s require mating forces low enough for manipulators to operate, even when full hydraulic controls pressure is on one side of the connection.

Flowline connection systems

Methods to make first-end connections by “laying to” the subsea tree or manifold and pulling the flowline into a guidance system and into a connector, and systems for initiating the flowline installation vertically and then “laying away,” leaving the flowline hubs horizontal and available to be pulled and latched together, have been developed and used numerous times. Vertical initiation systems have been designed to run on guidelines, or to use a wedge-shaped plug to orient the connection in guidelineless systems. Either metal seals or improved elastomeric seals provide reliable, long-life sealing. Guidance and pull in systems to allow second end connections have also been developed and are widely used.

With the improved capability of dynamically positioned vessels, availability of powerful work ROVs, and instruments to accurately measure the position of equipment on the seafloor, the most common flowline connection system today is the U-shaped jumper. These jumpers up to about 120 ft can be handled from many work boats and drilling rigs. Metocean measurements take about one day, and fabrication of the jumpers takes less than a day, depending on location and logistics. It is not uncommon to install a jumper connection in water depths of 3,000 ft in less than a day.

Multiphase pumping

Technology to allow long distance tie-backs has been the “holy grail” of subsea well systems since their inception. Pumps have been operating reliably for several years, and can be operated at distances up to about 12 mi. The limitation is use of surface controllers for the motors. Beyond this distance, the controls electronics must be located adjacent to the pump, and controls with capability to operate in deep water just now are under development. Providing sufficient power for long distances to significantly increase production from deep water fields still is a problem.

The way forward

As a testimonial to the oil industry, subsea well technology has come a long way since the ’50s. Consider that:

- Subsea well systems are among most profitable offshore projects, worldwide. They allow maximum use of infrastructure and developing reserves that are too small to be economic by other production systems

- Start-up times short are now short - normally less than 2 weeks. System availability over 99% is common

- Demonstrated capability to design systems for any reservoir or management plan - oil to 15-30 mi, gas to 100 mi, to 6,000 ft water depth and 15,000 psi.

The author’s view of subsea systems reliability /complexity against time is shown in Figure 5 (an intuitive collaboration of the author and Bil Loth). This plot shows system complexity (number of components in the system that must operate to accomplish all functions) and system maintenance reliability (time between failures that require repair to maintain function). Starting in the mid-’80s until today, the complexity of the systems is increasing dramatically as more “gadgets” become available, and reliability appears to be dropping seriously.

Possible causes for decreased reliability include the systems are getting so complex with so many components, it is not theoretically possible to build each component to the quality required to have a high total system reliability. In addition, oil companies and retirements have robbed the equipment suppliers of the experienced personnel required to build high reliability equipment.

Today’s systems engineers have a dual task of deciding what capability to put into a subsea well system while maintaining high reliability. Rather than put all the bells and whistles onto a system, the author suggests that engineers on every project do a cost/benefit analysis of system requirements, and what will be needed to get the system up and running. A thorough FAT (factory acceptance test) and SIT (system integration test) process should be followed as well to verify that the equipment meets the required specifications for installation and operation.

The author would like to acknowledge the sponsorship and support of Granherne and KBR.