Nanofiltration provides upgrade to injection program

Tony Vaughan

Statoil

Wayne Evans

Axsia

Jeremy Beckman

Editor, Europe

Last November, the Heidrun TLP became the first Norwegian platform equipped to remove sulfate from seawater. The nan-ofiltration membrane system, supplied by Gloucester, UK-based Axsia (part of the NATCO Group), was installed as part of a major water injection upgrade program, which included produced water injection. This had been commissioned by operator Statoil with the twin aim of boosting oil recovery – linked in part to the Heidrun North satellite development and reduction of scale deposition – and also to comply with new regulations requiring zero discharge of harmful by-products from Norwegian shelf operations.

Heidrun, located in 350 m of water in the Norwegian Sea, was brought onstream in late October 1995 by the development operator Conoco. Until recently, the field was still producing at its peak capacity of 190,000 b/d of oil and 6.0 Nm3/d of gas. Water injection had been applied from the outset for pressure support on production wells completed in the Fangst reservoir. The original system, incorporating acid back washable filters, could provide up to 2,186 cu m/hr of de-aerated seawater at an injection pressure of 175 bar. Serious barium sulfate scale build-up in the (Fangst) wellheads and well tubing occurred as a result.

To prolong plateau production, Statoil decided to target sections of the main reservoir (Åare and Tilje) for secondary recovery. Seawater injection had not previously been applied in these areas. While raising the volume of water required, Statoil opted for a combination of produced water reinjection and seawater injection with sulfate reduction using the membrane technique, which had been adapted successfully by Axsia to various platforms since 1988.

null

Membrane-based sulfate reduction was first applied offshore on Marathon's Brae A platform in the UK North Sea. That original system is still in service today. Others have since been installed by Axsia in fields off the UK (Janice, ETAP), and Angola (Kizomba A and B). Axsia is a sub-licensed original equipment manufacturer for application of the technique, which is patented by Marathon Oil and licensed by the Dow Chemical Co.

Statoil, along with the contractor VM (Modification and Mainten-ance) Alliance responsible for the water injection upgrade program, identified numerous benefits for Heidrun:

- The process would allow the wells to remain open, by reducing the scale potential and limiting the need for costly chemical injection

- No harmful discharge of produced water into the sea, in line with government requirements.

Based on Statoil's experiences elsewhere in the Norwegian and Danish sectors, Statoil contracted VMA and Axsia to install de-sanding hydrocyclones to the produced water injection system, to prevent solids build-up in the injection pumps. This complex project, which had to overcome severe space restrictions on the platform column top, led to the creation of the world's first dedicated hydrocyclone performance test bed.

Prior to commissioning the new equipment, Statoil requested engineering studies to examine the practicality of supplying the water volumes required for secondary injection into the Nord Flank and Lower Tilje and Åare sections of the main reservoir. The early assumption was that normally de-aerated seawater would serve as the primary source water. As the field matured, seawater injection would be lessened to accommodate increased flow of produced water.

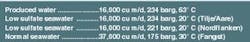

Statoil assembled a pilot produced-water injection plant to test the impact of produced water injection on the reservoir. It operated comfortably for over a year, demonstrating that produced water could be injected without any significant decline in injectivity. Another study commissioned Kværner to investigate the technical and commercial implications of reducing sulfate levels in the seawater. This study was based on the following flow rates:

This FEED study produced a concept for the project, which could then go out for tender.

The project was put out for an EPIC tender in mid-2001. Time constraints meant that Statoil had already procured numerous long lead items. These included two booster pumps (Kværner Eureka), two high-speed water injection pumps (Framo), and a produced water injection filter (40 microns) package (Betex).

In October that year, the VM Alliance of Fabricom and Sorco was awarded the contract to build the produced water treatment/injection plants, with Axsia – a participant in the VMA tendering team – sub-contracted for the sulfate reduction package and de-sanding hydrocyclones in January 2002.

Water injection plant

The water injection module (M 343) is approximately 16 x 12 m and 10 m high, with an installed weight of 500 tonnes. The module, which contains three injection pumps each of 7500 hp, is installed on top of the existing M 30 Process module.

The pumps are initially configured as 2 x low sulfate water injection and 1 x produced water injection. As the produced water volume increases, however, the design of the manifolds will quickly allow the duty of the pumps to be changed to 2 x produced water and 1 x low sulfate water injection.

The requirement to inject produced water, which is classed as a hydrocarbon, dictates that the injection module be located within a hazardous area, as opposed to the original seawater injection pumps, which are located in the M 10 utility module.

The seawater injection system retains it's original design capacity.

Low sulfate water

Statoil's production prognosis called for a 32,000-cu m/d (200,000-b/d) membrane separation system producing low sulfate seawater at a guaranteed quality of 40 mg SO4 /liter. The system designed by Axsia is supplied with 42,700 cu m/d (267,000b/d) of strained and chlorinated seawater. The water is then passed through the acid back washable filters, the existing filters having been upgraded by the addition of three further filter vessels. This allowed the filter flux rate to be reduced in order to achieve the required silt density index (SDI) of 3.5. This ensures that colloidal and small particulate matter does not foul the membrane. The water is then pressurized and passed through cartridge filters prior to separation of divalent ions (i.e. of sulfate, calcium, and magnesium) within the membrane system. Each of the four membrane trains feature Dow Filmtec SR90-400 nanofiltration membrane elements. Axsia also supplied an off-line membrane cleaning facility.

There were some design challenges.

- Statoil had specified that all piping and materials in contact with 20° C seawater should be made from titanium. There are only limited numbers of companies qualified to work with this material, and a limited number of skilled welders. Axsia could identify only two specialist yards, one in Norway and the other the Babcock yard in Rosyth, Scotland who were ultimately awarded the sub-contract.

- The low temperatures at this northern latitude. In warm water regions such as West Africa, the seawater temperature doesn't vary. On Heidrun, the system has to operate at 20° C, as the water is passed through the coolers on the crude oil train. Early on, it became apparent that it would also have to be capable of operating at temperatures of 7° C to maintain flow into critical wells when the oil production is shut down. This change required the hydraulics to be re-engineered.

Being a Norwegian sector platform, the equipment and installation also had to fully comply with Norsok requirements, in terms of operator access, lifting, and so on. That meant introducing significant changes to the way the plant was laid out, including the method for inserting and changing out the membranes. A mechanical handling study was necessary to ensure that membranes (each weighing 33 kg when wet) could be changed safely and efficiently.

The other real challenge was the drainage. The sulfate reduction plant rejects 25% of the water produced, or around 11,000 cu m/day. That leads to an overflow, which could not be accommodated in the deck's existing drains. So new drainage lines had to be installed – a complex operation on an existing platform.

Heidrun's H 15 sulfate reduction plant module is fully enclosed and environmentally controlled with heating and ventilation systems.

Produced water treatment

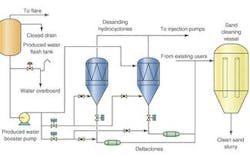

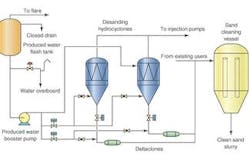

When the contract was awarded to VMA in late 2001, the original premise was that produced water with an oil content below 40 mg/l would be sent from Heidrun's existing flash tank at 1.4 bar to a produced-water booster pump. The water would then flow through a 40-micron filter package before entering a booster and injection pump pressurized to 234 bar.

Statoil, however, wanted to remove suspended solids of 40 microns-plus from the produced water, due to concerns over potential seal damage in the injection pumps. With the knowledge that the produced water contained napthanic acids, there was some doubt that a wedge wire type strainer would be successful.

The VM Alliance was asked to investigate the use of de-sanding hydrocyclones as an alternative. During the pilot injection project, Axsia Mozley hydrocyclones had successfully protected the reciprocating injection pump. As Heidrun's produced water would not feed through at a constant flow rate (due to process interruptions or occasional well shut-ins), the study needed to determine the optimum number, capacity, and configuration of the hydrocyclones.

Heidrun's TLP was already equipped with a produced-water treatment system comprising de-oiling hydrocyclones followed by a flash vessel, from which produced water had been sent overboard. Under the new scheme, reinjection water would be taken from the outlet line associated with this vessel, which has a pressure slightly above atmospheric level. Produced water would be pumped through the new de-sanding hydrocyclones to the water injection pump inlets, pressurized at 5 bar. The hydrocyclone underflow was directed to the existing sand cleaning system to further minimize environmental impact, with the sand slurry being cleaned before being discharged overboard.

Produced water flow was expected to rise from 5,000 cu m/d, once the system began operating, to a worst case scenario of 39,000 cu m/d by 2010, as water cut increased. This variation was considered too great for a hydrocyclone system to manage without intervention, and Statoil had stipulated minimal manual intervention for safety reasons. It was also targeting 98% availability, which limited the scope for enforced production downtime.

Axsia evaluated three options, based around a Mozley Sandspin S2C050606 hydrocyclone, which has a capacity of 19.1 cu m/hr at 5 bar differential pressure, reduced to 13 cu m/hr at 3 bar. These options were:

- A single hydrocyclone vessel capable of treating all the flow, but would require frequent shutdowns to adjust the cyclone capacity to match operational requirements

- Two vessels, with respective capacities of 13,000 and 26,000 cu m/d, allowing hydrocyclone numbers to be altered early on without the need for a shut-down

- A 2 x 100% option, which would provide greater operational flexibility, without the need for any shutdowns.

Statoil opted for the latter, as it guaranteed the system's operability through the general build up in volume and would handle fluctuations in flow due to well intervention without the requirement for shut downs.

The hydro cyclone system could also be maintained without the need to discharge produced water to the sea. The final design incorporates the largest desander cyclone vessels so far produced by Axsia.

Following analysis of two surveys commissioned for the produced water re-injection pilot test, the design value for suspended solids was fixed at 100 mg/l. Sand separated at the hydrocyclone underflows would be treated in Heidrun's existing vertical sand-cleaning vessel. To interface with this vessel, further parameters would have to be accommodated:

- The hydrocyclones had to operate normally with a closed underflow, solids being collected within the hydrocyclone vessel for batch discharge, thereby minimizing the volume to be treated

- The hydrocyclone vessels had to store separated solids for at least 12 hr, to allow completion of sand jetting from the production separators into the sand-cleaning vessel

- Maximum batch volume to the sand-cleaning vessel kept to 13 cu m

- As the vessel is positioned 70 m away from the hydrocyclones, and has an elevation 5 m above the hydrocyclone discharge, the sand slurry must be trans- ported to the sand-cleaning vessel without settling.

In response to the 12-hour storage requirement, Axsia devised an accumulation section in each hydrocyclone vessel capable of holding and treating up to 1,950 kg of solids, or around 4 tons/day. Sand discharge and transportation, at a rate of 13 cu m/hr, were designed based on work at Axsia Mozley's laboratory in UK.

The accumulation section of each hydrocyclone vessel was designed as a cone, to help slurry flow out, with spray nozzles being installed in each vessel to fluidize the sand prior to discharge. A dilution connection was also installed on each nozzle of the solids outlets to limit slurry concentrations to below 15% v/v. This connection also served to flush the slurry lines after use.

On Heidrun, the operating requirements for the hydrocyclones were set as follows:

- Capacity - 39,000 cu m/d

- Operating differential pressure - 3-5 bar

- Separation - d98 < 40 microns at 3 bar dP

- Max. inlet solids concentration - 100 mg/l

- Solids density - 2,650 kg/cu m

- Water density - 1,036 kg/cu m

- Water viscosity - 0.5 cP

- Water temperature - 68° C

Statoil wished to witness factory performance tests, as it was not possible to test hydrocyclones in the field. Axsia was requested to come up with a test procedure. The company invested in a specially designed test rig at our UK laboratories, the first instance of performance testing for this type of technology anywhere in the world. The test facility has since been used for other projects.

Tests witnessed by Statoil and VMA showed that if anything, Axsia had slightly overestimated Heidrun's operating conditions. The selected hydrocyclone met the separation efficiency required, but correlation's used to determine the system's capacity did not account entirely for actual differences in density and viscosity. This led to a further three hydrocyclones being added to each vessel.

Space restrictions on the platform's deck meant that the hydrocyclone package had to be installed on top of the H 30 column, while the injection pumps were located in the M 343 module situated on the weather deck of the M 30 process module. In fact the hydrocyclones would be placed directly above the platform tether intervention equipment supporting pins that could be subject to periodic use.

The design was modified, with the package structure elevated to allow access below for tether intervention activities. As there is a tendency for ice to accumulate and drop from the flare boom above the H 30 location, the cyclone plant was installed with a pitched roof and dropped-object protection.

Retrofitting of the de-sanding hydrocyclones into the produced water treatment module was completed successfully, in time for produced water treatment to re-start in June 2003 (and prior to the start of water injection in November). The system, which can treat 245,000 b/d of produced water, has so far performed to expectations.