Lukoil/Seaway progressing first Russian Baltic project

Nick Terdre

Contributing Editor

Lukoil is leading the first offshore develop-ment in the Baltic Sea off the Russian enclave of Kaliningrad. The Kravtsovskoye oil field in block D6, which is operated by the Russian company's subsidiary Lukoil-Kaliningradmorneft, is due to come onstream in late 2003.

The field is being developed with two platforms, the transport and installation of which have been contracted to Seaway Heavy Lifting. Offshore installation by SHL's crane vessel Stanislav Yudin is due to take place in August and September, according to Youri Vorobiev, SHL's project manager for the full scope of work.

Lukoil and SHL have been involved for several years. Lukoil-Kaliningradmorneft is the owner of the Stanislav Yudin, along with Stolt Offshore, a partner in SHL, the joint venture company that has managed and operated the vessel since 1991.

One of the jackets to be used in the Krav-tsovskoye development comes from an earlier phase of the development work. SHL completed installation of this eight-leg jacket in 2000 with the installation of the skirt piles.

SHL's scope for this summer includes the installation of a living quarters module on the existing jacket, plus the installation of a drilling and processing platform with an eight-leg jacket. Unusually, the jacket incorporates a protection frame at sea level for the 20 conductors. Ice is a possible risk though it does not occur every winter in this part of the Baltic, Vorobiev says.

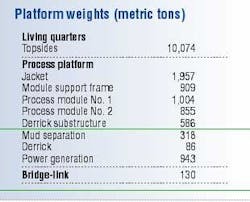

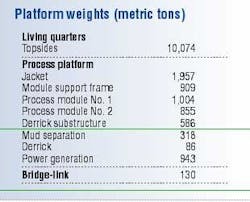

A module support frame with water and storage tanks built into it will be installed on the jacket, on top of which will go modules for power generation, drilling, and process facilities. The drilling facilities will be installed in three lifts – derrick substructure, mud separation module, and derrick. The total topsides will weigh 6,660 metric tons. A 70-m bridge will link the drilling and process platform with the living quarters.

The various structures are being built at Kaliningrad Fabri-cation yard, a Lukoil subsidiary, in Kaliningrad. SHL will use four barges to transport them to the field, though two of the barges will make two trips each, making a total of six trips. Kravtsovskoye lies 24 km offshore in a water depth of 30 m.

The earliest start date for the offshore installation is Aug. 23. SHL has allocated 21 days for lifting and construction operations. The whole operation is scheduled to be completed by mid September, opening the way to offshore hook-up and the start of development drilling.

Processed oil will be exported to shore by a 45-km, 10-in. pipeline to be laid by Potvodtrubostroy, a Russian marine contractor. It will also travel through a section of onshore pipeline to a new Lukoil terminal.

SHL strategy

Now in its 12th year of operating Stanislav Yudin, SHL has been implementing a strategy that takes it beyond its home market of the North Sea in search of work. Not only is demand in the North Sea much lower now than in the mid and late 1990s, but there is usually little activity in the winter period from October to April because of the likelihood of having to spend time waiting on weather, says Marketing and Business Development Manager Aart Ligterink.

In this period SHL instead aims to be active in the Middle East market, and as the vessel has to sail through the Mediterranean to get there, it is available for work in this area too. With an average sailing speed of 8-9 km, the Stanislav Yudin can get from the North Sea to the Mediterranean in 17 days.

Activity levels in the Middle East market are reasonably high, buoyed not least by Iran's multi-stage South Pars development and the participation of foreign oil companies in it. SHL has worked on parts of all the first five stages, including installing a deck in phase three and jackets in phases four and five. It was awarded the South Pars 4 and 5 deck installation in late 2003. It is also tendering for work in phases 6, 7, and 8, for which offshore construction is also scheduled for late 2003 or early 2004.

In Iran, SHL often works with Iranian Offshore Engineering Co., a main contractor whose capability includes heavy lift, pipelay, and fabrication. Jointly with IOEC, SHL installed the first two wellhead platforms of the South Pars development using IOEC crane barge Abouzar 1200.

null

SHL is currently negotiating with Romanian company Petreco for the installation of a small platform in the Black Sea this autumn. Such an assignment would fit the strategy of performing jobs in the Medi-terranean en route to the Middle East, Ligterink says.

The Yudin's summer schedule in the North Sea started in July, with the installation of Wint-ershall's Q4-C platform in the Dutch sector, involving a 1,200-ton jacket and 1,800-ton deck. The vessel was next due to move to the UK southern basin to install Shell's Carrack platform (jacket 1,250 tons, topsides 2,200 tons) and the Clipper PR platform (jacket 800 tons, topsides 1,000 tons). This job is a subcontract from SLP Engineering, a UK fabricator with which SHL has executed many projects over the years.