Evolution of minimal platform concepts for marginal developments

Proprietary structure growth reflects industry needs

Robert Rosenblum

Atlantia Offshore Limited

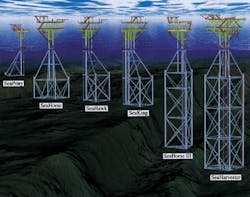

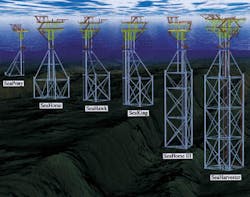

Atlantia's SeaHorse family of platformsMinimal platforms were born in the late 1970's when major oil companies, burdened with the responsibility of developing a marginal lease or returning it to the government, decided that it would be better to farm out the lease to smaller independent oil companies. These independents were open-minded and receptive to new technologies. The minimal platform concept fit well with their development philosophy by decreasing capital expenditures and reducing the time required to bring new production on stream.

The use of minimal platforms did not become prevalent until the mid-1980s. In 1982, the industry experienced a significant downturn as a result of over-development during a period of high oil prices. Oil companies that had become prosperous in the 1970s were now faced with an economy that could no longer support their large operational budgets.

Forced to reduce costs, they began by cutting staff and postponing or eliminating all but the most lucrative projects. Finding ways to reduce capital expenditures on marginal projects became the most important part of every development scenario.

Oil prices behave cyclically, and when they began to rise again in the early 1990s a new breed of oil company emerged. The majors had seen the bad times and were more receptive to working with the independents in farming out smaller marginal field properties.

The independents had successfully used minimal platforms and proven them as a viable commercial technology. Even major oil companies began deploying minimal unmanned platforms as satellite test facilities, tied back to existing production platforms for processing. Several small engineering companies, sensing the demand for minimal platforms, soon entered the market with their own proprietary designs. This point marked the expansion of minimal platforms in the oil and gas industry.

To be more globally competitive in the oil and gas industry, North Sea operators are working with service companies to persuade government regulatory bodies to relax unnecessary requirements. To date, several minimal platform concepts have been developed or modified from Gulf of Mexico designs and installed in the southern sector.

Atlantia Offshore Limited's focus is the development of economical platform concepts for marginal developments, and the reduction of costs during design and fabrication. New platform concepts allow Atlantia to decrease structural weight and reduce fabrication costs.

The firm's SeaHorse platform was developed in 1982 and originally designed to support a single conductor and small test facility, in water depths less than 100 ft. This jacketed structure consists of four skirt piles and one or two surface piercing columns to support the deck. This platform can be fabricated in 6-10 weeks and installed by a jackup drilling rig. In some instances, this has eliminated the need for a costly mudline suspension of the well and has reduced installation costs by eliminating the need to mobilize an expensive derrick barge spread.

To provide support for smaller satellite platforms, the SeaHorse platform was optimized, removing two of the skirt piles and providing a vertical structural member to act as the main leg of the jacket. This modified SeaHorse platform was dubbed SeaPony, and until the further refined SeaHorse III platform was developed, it was one of the most widely used of Atlantia's proprietary platforms.

As interest in the SeaPony and SeaHorse platforms grew, their designed water depths have increased to well over 200 ft. With this increased water depth came the request for full gas processing capabilities. To accommodate the increased deck size requirements and crane capacities, the SeaPony platform was modified, through the addition of two deck legs, to provide a three-point support for the deck. This new structure, the SeaHawk platform, can support the required production equipment in water depths of up to 300 ft.

In order to adequately distribute the loads from these larger decks into the jacket, several diagonals were added to form an under-deck truss, also referred to as a "spider deck," since its diagonals resemble the legs of a spider supporting the deck. The diagonal framing of the spider deck can be easily adjusted to support many different deck configurations, providing the versatility necessary to support both new and salvaged deck structures.

The SeaKing platform was specifically designed to allow non-obstructed wellhead access by a cantilevered or slot-type drilling rig by locating the wellheads at the extreme edge of the deck. The jacket's structure is framed on the far side of the wells, away from the drilling rig, to allow adequate clearances between the jacket and the base of the drilling rig. Due to the structural framing inherent in this platform, it can be designed to easily accommodate up to six wells, in contrast to the SeaHorse and SeaPony platforms, which are typically designed for 1-4 wells.

The concepts developed to this point were for minimal unmanned gas platforms. In order to provide Atlantia's clients with an economical platform capable of handling oil production and supporting workover/drilling rig operations in water depths where conventional jackup rigs cannot operate, Atlantia returned to the original SeaHorse concept and created the SeaHarvester platform. The SeaHarvester provides four columns for support of the deck structure, which increases its payload capacity and provides support for up to twelve wells in water depths of 300-650 ft.

The firm's minimal platforms have come a long way from original SeaHorse, which began as a small gas test facility, to the high capacity SeaHarvester drilling and production platform. Significant increases in both deck payload and water depth have caused increases in the natural period of these structures.

In order to better assess these effects on the platform's dynamic response, Atlantia deployed a bi-axial accelerometer package on a SeaHarvester in 367 ft of water during the winter of 1998, while drilling operations were underway. The resultant motions were compared to values provided in the ISO 6897-1984 (E) curve, "Suggested Satisfactory Magnitudes of Horizontal Motions of Structures." The platform's response was well below the curve for fixed offshore platforms.

Floating platforms

In October of 1998, British Borneo Exploration brought onstream the first SeaStar TLP platform on their Morpeth field (Ewing Bank 921). This marginal field was turned into an economically viable project through the use of the patented SeaStar. The SeaStar is the first mono-column tension leg platform (TLP) installed in the world. It enables the economic development of marginal reserves in water depths beyond 6,600 ft. Atlantia is currently fabricating its second SeaStar platform for British Borneo's Allegheny field development.In developing the SeaStar platform, emphasis was placed on applying platform concepts developed in the evolution of the SeaHorse platform, wherever possible. While the SeaStar's hull is unique, the deck's support structure was created by incorporating the SeaHarvester's spider deck into the lower deck's framing, to create an under-deck truss. This truss allowed for a reduction in the diagonal framing between the deck levels, providing a more effective utilization of space for the equipment. For fixed platforms, from project award to loadout, including installation of the production facilities, onshore hookup and commissioning are often completed in less than sixteen weeks.

Several factors contribute to achieving this fast-track schedule. Standardization and optimization of the structural design, through the reduction of complex joint framing details and design of easy-to-fabricate box sections for the jacket, helped to reduce fabrication time requirements.

Facilities procurement and fabrication usually control the overall schedule. Atlantia pre-bids and then short-lists equipment suppliers and fabricators in order to attain confidence in working with companies that have a reputation of performing well on fast-track schedules.

Author

Robert Rosenblum is a Project Manager at Atlantia Offshore Limited, specializing in the supervision of turnkey contracts from engineering through installation. He has eight years of experience in the field of offshore platform design and project management concentrating on minimal platforms in the Gulf of Mexico. He holds a BS in Maritime Systems Engineering from Texas A&M University at Galveston.

Copyright 1999 Oil & Gas Journal. All Rights Reserved.